Abstract:

The casting process design and production practice of the 12V190 cylinder head, a critical component for a gas engine. By analyzing the compact and thin-walled structure of the cylinder head and formulating a casting process plan, combined with reasonable control of material chemical composition and vermicular inoculation treatment, effective measures such as improving the sand core structure were implemented. This resulted in the production of cylinder head castings that meet customer technical standards, reducing production costs and improving product quality.

1. Introduction

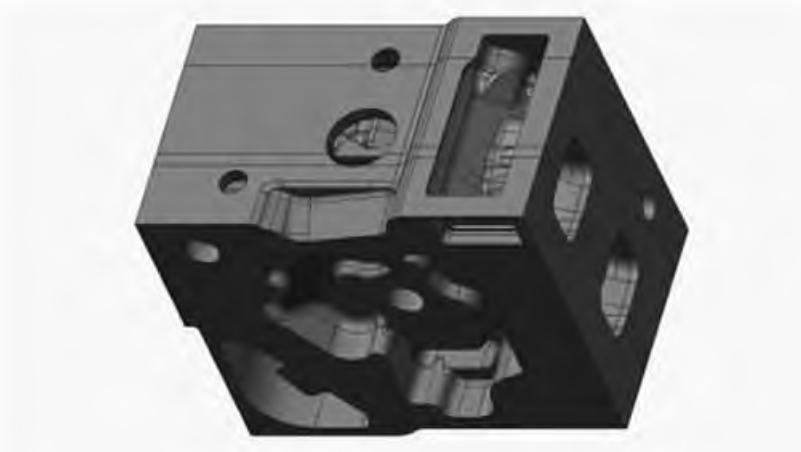

The 12V190 cylinder head, as a key component of a gas engine, is characterized by its complex internal surfaces of the air passages and cooling water chambers, thin local wall thickness, and compact overall structure. Due to its unique operating conditions, the cylinder head material must possess higher heat resistance and fatigue resistance compared to those used in diesel engines. Therefore, the casting process for this cylinder head is relatively complex and challenging. Unreasonable casting process design can lead to an increased risk of casting defects such as slag inclusion, cold shuts, and porosity, resulting in a higher scrap rate.

2. Casting Process Design

2.1 Overview of the Casting Process

Drawing on the casting process of cylinder heads for diesel engines and combining existing tooling conditions, the product structure and process were designed as one mold for two pieces. Dedicated tooling was used for the sand box, with a sand-to-iron ratio of 1.66:1. The casting linear shrinkage rate was designed to be 1%, and a machining allowance of 5mm was set for the combustion surface, intake surface, and exhaust surface. The molding and core-making methods combined machine molding, machine core-making, and manual core-making. Water-based graphite paint was used for the mold, while alcohol-based graphite paint was applied to the sand cores through brushing and dipping. The mold assembly adopted a layered core assembly process.

Table 1: Overview of Casting Process Parameters

| Parameter | Value |

|---|---|

| Sand-to-Iron Ratio | 1.66:1 |

| Casting Linear Shrinkage Rate | 1% |

| Machining Allowance | 5mm |

| Molding Method | Machine molding & manual molding |

| Paint Type | Water-based graphite & alcohol-based graphite |

2.2 Core Material and Process Methods

Based on the product structure and existing process levels, furan resin sand was used for the upper and lower molds and the peripheral contour sand cores. Coated sand was used for the internal chambers such as water chambers and air passages. The use of coated sand cores facilitated better dimensional accuracy of the internal chambers and good collapsibility, which was conducive to the subsequent cleaning of internal core sand, ensuring the cleanliness of water chambers and air passages. The cylinder head was designed with six bolt connection holes distributed evenly from top to bottom, which were directly cast out. Therefore, electrode graphite material was used for the bolt hole cores, ensuring core strength, preventing core breakage during mold assembly, and providing a certain chilling effect to prevent porosity defects in the casting, ensuring a dense internal structure of the casting.

2.3 Ventilation Design of the Casting Mold

Due to the large amount of gas volatilized by furan resin sand and coated sand under the action of high-temperature molten iron, the inability to effectively vent the gas from the mold cavity in a timely manner can easily lead to porosity defects in the casting. Therefore, effective ventilation of the mold during pouring is crucial. Combining the cylinder head structure and core process, five 30mm×10mm×300mm exhaust risers (commonly known as flat risers) were designed on the upper mold. Ø10mm×300mm vent holes were designed on the top of the triangular core, spark plug core, and auxiliary water chamber core heads. Ventilation grooves were designed on the side wall of the lower mold for auxiliary ventilation of the gas on the side of the water chamber core head during pouring. If needed, ventilation holes could also be drilled manually on the side wall of the lower mold to enhance the ventilation capacity of the mold during pouring.

2.4 Pouring System Design

Considering the many curved surfaces in the internal water chambers and the locally thin wall thickness of the cylinder head, the pouring system design was based on the principle of “smooth molten iron filling, good slag removal effect, and uniform mold temperature field” according to the theory of proportional solidification. A straight pouring gate with molten iron filtration function and a gating basin were designed, along with slow-flow cross gates distributed on the upper and lower molds. The cross gates allowed molten iron to flow through the “overlapping” form of the upper and lower molds. At the same time, layered and dispersed “step-type” ingates were designed to allow molten iron to enter the semi-closed pouring system of the cylinder head casting. The cross-sectional ratio relationship of the gates was ΣAin:ΣA横:ΣA直 = 1:1.5:0.53. This pouring system ensured smooth molten iron filling with good slag removal, resulting in a uniform temperature field within the mold cavity. The solidification process of the casting basically achieved simultaneous solidification, reducing the risk of casting defects such as slag inclusion, cold shuts, and porosity.

Table 2: Pouring System Design Parameters

| Gate Type | Description | Ratio |

|---|---|---|

| Straight Pouring Gate | With molten iron filtration function | ΣA直 = 0.53 |

| Cross Pouring Gate | Slow-flow design | ΣA横 = 1.5 |

| Ingate | Layered and dispersed “step-type” | ΣAin = 1 |

2.5 Melting and Pouring Process

The chemical composition control for melting was based on the principle of “high carbon equivalent, low phosphorus and sulfur content, and a certain manganese content”. Considering the locally thin wall thickness of the cylinder head, the carbon content was controlled at the upper limit.

Vermicularization and inoculation treatment: The tapping temperature was controlled between 1510~1550℃, and vermicularization treatment was carried out in the ladle using the in-stream method. After vermicularization, an inoculant was added to the surface of the molten iron for inoculation treatment. After inoculation, 0.1%~0.15% of cryolite powder based on the total volume of molten iron was covered on the surface. Pearlite was used for slag removal at least 4~5 times to clean the slag and impurities in the ladle. The pouring temperature was controlled between 1360~1390℃, and the pouring speed was controlled at 20~25s/mold, with a pouring mass of 200kg/mold. During pouring, attention was paid to mold ventilation and molten iron slag blocking operations to ensure a smooth and orderly pouring process. After pouring, the mold was allowed to cool for 12 hours before opening and cleaning operations were performed.

3. Process Testing and Validation

After the design of the cylinder head casting process, molds and tooling were produced, followed by subsequent process testing and validation based on actual conditions. Operations such as molding, core-making, and paint application were carried out according to the requirements of the process plan. The mold assembly process involved assembling the internal chamber resin sand supplementary cores and coated sand cores in four layers according to the principle of “from outside to inside, from bottom to top”. Firstly, the first layer of peripheral contour supplementary sand cores was placed in sequence. Then, round steel core supports were placed at the center core seat position of the lower mold. Subsequently, the cores were placed layer by layer according to the specified core-placing sequence. The joint surfaces between the lower water chamber core head and the lower mold core seat, as well as between the auxiliary water chamber core and the lower water chamber core, were bonded using casting glue. The amount of casting glue water used between each layer of sand cores was controlled appropriately to ensure that the sand cores bonded with casting glue were firm, and there was no glue overflow or other issues. During the core-placing process, a special wall thickness gauge was used to check the wall thickness of key internal areas. Any issues encountered during core-placing were promptly adjusted. After core-placing, the molds were grouped, stacked, and lifted to the surface-drying oven for drying.

4. Test Results and Analysis

4.1 Pouring Process and Observations

Melting was conducted utilizing a 5-ton medium-frequency induction furnace to produce the molten iron. The initial pouring temperature was set at the upper limit of the specified pouring temperature range, which was 1390°C. This ensured that the iron would maintain a sufficiently high temperature to facilitate proper fluidity and filling of the mold.

The pouring process adhered to the “slow-fast-slow” principle to guarantee a smooth and orderly operation. This method involves initiating the pour slowly to prevent splashing and turbulence, increasing the pouring speed to efficiently fill the mold, and then slowing down again near the end to minimize any potential disruptions or entrainment of air or impurities. The actual pouring time achieved was 23 seconds per mold, which was within the desired range for this process.

During the pouring process, careful attention was paid to ventilation and slag blocking operations. Ventilation was crucial to allow the escape of gases produced during the solidification of the molten iron, preventing the formation of porosity defects. Slag blocking operations ensured that impurities and slag were effectively prevented from entering the mold, thereby maintaining the cleanliness and integrity of the casting.

No common issues such as “boiling” (a term used to describe vigorous gas evolution and bubbling within the mold, often indicative of excessive gas content or poor ventilation) were observed during the pouring process. This indicated that the ventilation system was functioning adequately and that the molten iron was of good quality, with minimal gas content.

4.2 Chemical Composition and Mechanical Properties Analysis

Following the pouring and solidification of the castings, samples were taken for chemical composition and mechanical properties analysis. The results of these analyses are summarized below:

- Chemical Composition: The chemical composition of the castings was found to be within the specified limits. The carbon (C) content was 3.77%, silicon (Si) was 2.63%, manganese (Mn) was 0.73%, phosphorus (P) was 0.031%, and sulfur (S) was 0.010%. The copper (Cu) content was 0.66%, which was also within the desired range. These chemical compositions contributed to the desired mechanical properties and microstructure of the castings.

- Mechanical Properties: The mechanical properties of the castings were tested and found to exceed the specified requirements. The ultimate tensile strength (Rm) was 402 MPa, the yield strength (Rp0.2) was 330 MPa, and the elongation at break (A) was 4.0%. The蠕化率 (vermicularization rate) was 85%, indicating a good distribution of vermicular graphite in the microstructure, which enhances the thermal conductivity and fatigue resistance of the castings. The matrix microstructure consisted of ferrite (F) and 45% pearlite (P), with a hardness of 187 HB.

4.3 Dimensional Accuracy and Internal Quality Assessment

The castings were inspected for dimensional accuracy using a coordinate measuring machine (CMM). The results showed that the contour dimensions of the cylinder heads met the design requirements, and the machining allowances on the combustion surface, intake surface, and exhaust surface were reasonable.

An internal density dissection inspection was conducted on the cylinder heads to assess their internal quality. This inspection revealed that the internal microstructure was dense and free of defects such as porosity. The wall thickness measurements showed that, with the exception of a localized area near the spark plug hole in the lower water jacket and the air passage, which was slightly thinner than specified (measured at 3 mm instead of the required minimum of 8 mm), the rest of the casting met the design requirements for wall thickness.

4.4 Analysis of Issues and Improvements

The thinner-than-specified wall thickness near the spark plug hole was analyzed, and the cause was identified as a lack of sand core positioning during the molding process. The round steel core support, which was intended to support the sand core, did not provide adequate positioning, allowing the sand core to shift during pouring due to the static pressure and buoyancy of the molten iron.

To address this issue, the sand core structure was improved by incorporating positioning pins into the spark plug hole sand core. Additionally, the use of the round steel core support was discontinued, as the improved sand core design provided sufficient strength and positioning accuracy. These modifications ensured that the spark plug hole sand core was accurately positioned during the molding process, preventing shifts during pouring.

Following the implementation of these improvements, another round of testing and validation was conducted. The results showed that the wall thickness in the critical area was now uniform, with measurements ranging from 7 to 8 mm. This confirmed that the taken measures were effective in addressing the wall thickness issue.

In conclusion, the casting process for the 12V190 cylinder heads was successfully developed and validated through a series of tests. The use of multiple core materials, such as furan resin sand, coated sand, and electrode graphite, along with a combination of machine molding, hot-box core shooting, and hand molding methods, significantly improved production efficiency and reduced costs. The implementation of a slow-flow layered dispersion pouring system with iron filtration capabilities effectively addressed issues related to iron purification and prevented defects such as inclusions, cold shuts, and porosity. By carefully controlling the chemical composition and optimizing the sand core structure, the castings achieved the desired mechanical properties and microstructure, meeting or exceeding customer specifications.