The acceleration of urbanization in China has promoted the increasing demand for infrastructure construction such as highways and railways, as well as real estate projects. With the continuous increase of infrastructure projects in China, the market demand for excavators has also increased. Especially large excavators, due to their large excavation force and high operating efficiency, have been widely used in large quarries and mines.

Large excavators have high requirements for the reliability of structural components, and users hope that the structural components will not break during their entire life cycle, otherwise it will seriously affect the value of their second mobile phone. In response to multiple fracture failures of the front support of a 30t excavator’s boom steel casting during use, a macroscopic analysis was conducted on the fracture surface of the front support, combined with metallographic structure, chemical composition, and mechanical performance testing of the fracture surface of the failed steel casting, to determine the fracture nature and cause of the front support. To prevent the occurrence of such fracture failures, suppliers are required to adjust their casting and heat treatment processes to avoid casting shrinkage, crack defects, and more brittle Weinsteinite structures.

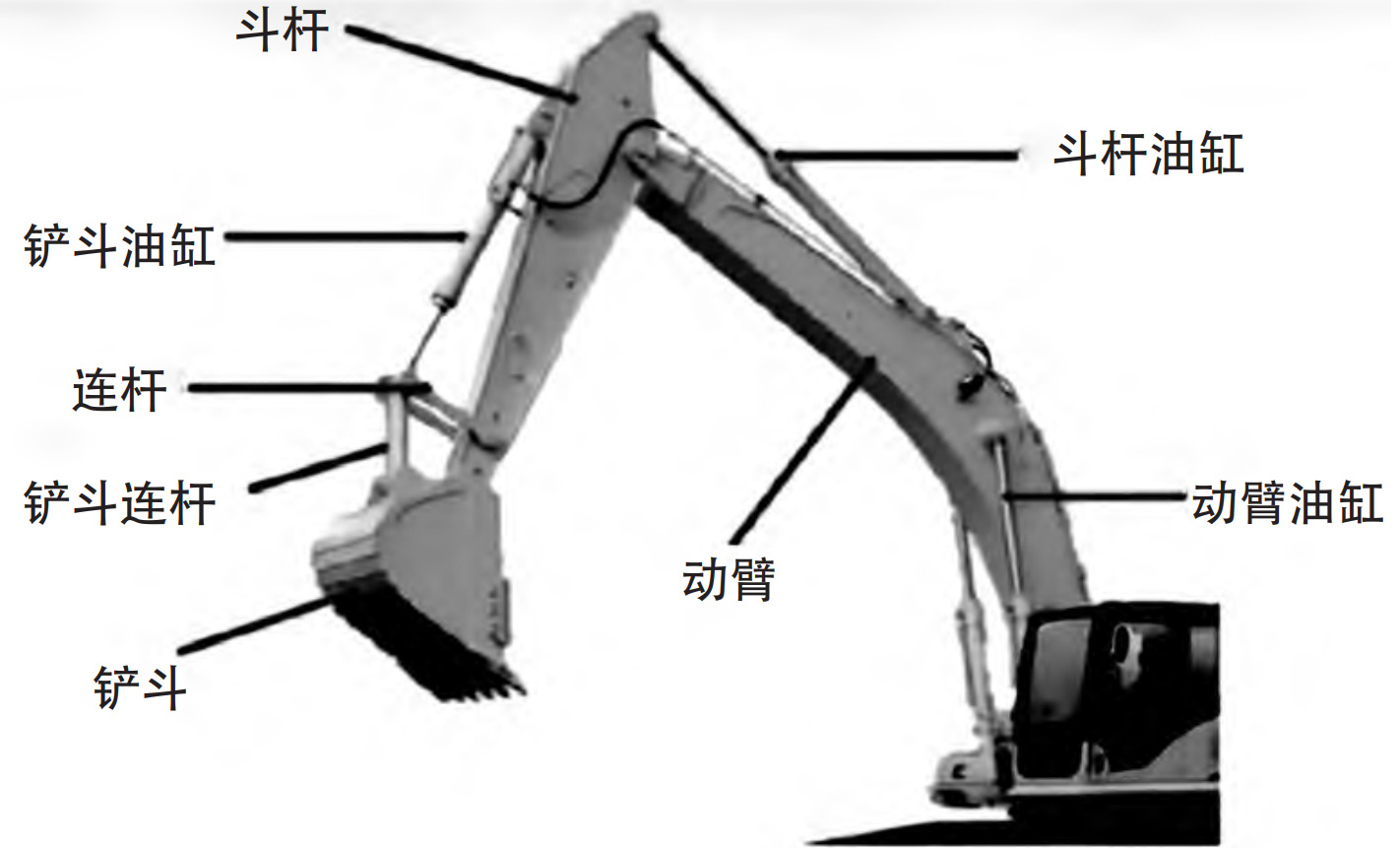

The working device of the excavator mainly consists of a boom, a stick, a connecting rod, a bucket, a cylinder, etc., as shown in Figure. The boom and bucket are the main load-bearing components of the working device, and the connecting part between the boom and bucket is the boom front support, which is one of the key components of the excavator boom.

There are three main structural forms of the front support: the first type consists of all parts made of sheet metal and manufactured by welding; The second type of motherboard on both sides is formed by casting and then welded to the connecting plate, while the third type of support is integrally cast. The main domestic manufacturers and Hitachi Construction Machinery excavators in Japan adopt the first structural form; The medium and large excavators of Caterpillar in the United States and Kobe Steel Construction Machinery in Japan adopt the second structural form; Komatsu of Japan adopts the third structural form for medium to large excavators.

In the early products of domestic manufacturers, the support of the working device was mainly composed of welded plates. Due to its complex structure, the welding process cannot be well controlled (poor transition), resulting in stress concentration and greater stress at the support, leading to cracking and failure of the support. In view of this, some domestic manufacturers have directly changed the support from plate welded parts to integral cast steel parts. Steel castings are made by pouring molten steel into molds, which can be used to create corresponding structures, effectively avoiding cracking caused by factors such as complex structures and poor transitions. However, if the control of the steel casting process is not in place, it can also cause cracking of the support.