Ductile cast iron containers can be used not only for the storage and transportation of spent fuel, but also for the storage of medium and low-level radioactive waste produced in the post-treatment process of nuclear spent fuel. In the process of spent fuel reprocessing, it is inevitable to produce activated components and radioactive wastewater.

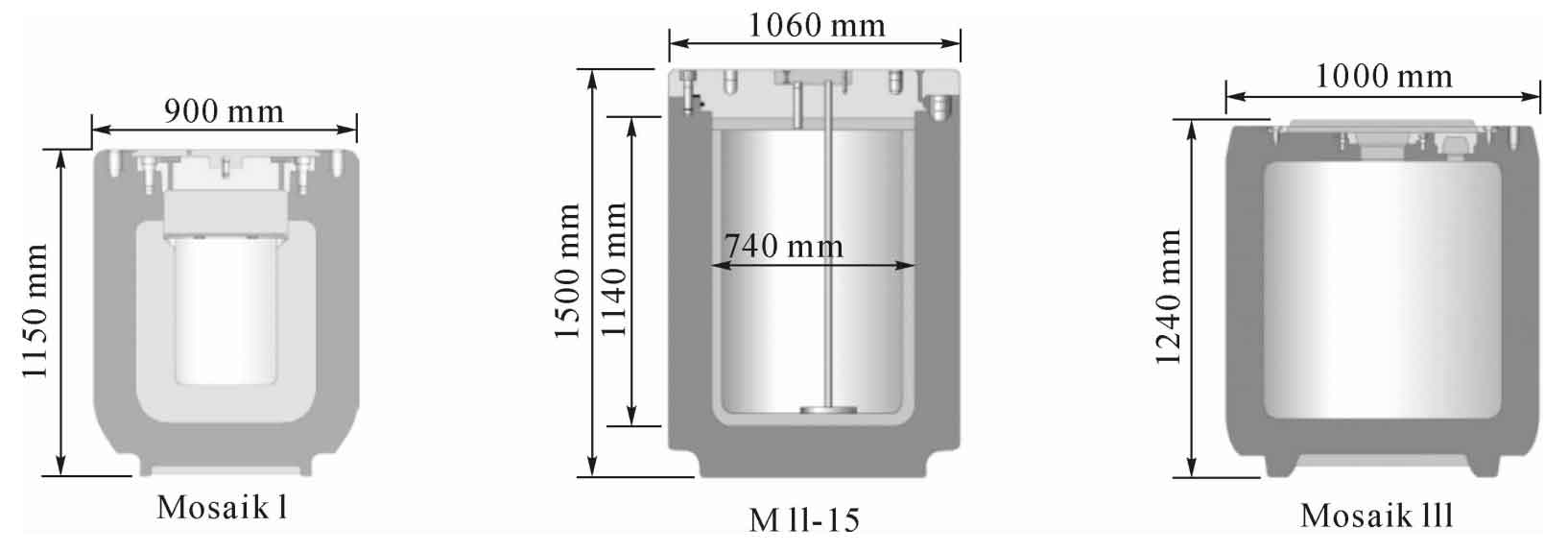

Germany has developed “mosaik” series ductile cast iron containers, which are mainly made of ductile cast iron and equipped with shielding cover and protective cover. Its wall thickness is usually 150 ~ 200 mm and its weight is 3.5 ~ 5.0 t.

By changing the end cover design and adding lead shielding layer, its different models can place almost all low-level radioactive wastes, such as being used to load activated parts in underwater or hot chamber, or directly dehydrate and evaporate other filter materials such as ion exchange resin, absorb and dry the concentrate and its mixture.

Due to its good corrosion resistance, the maximum corrosion depth of nodular cast iron bucket in 300 years is expected to be 22.5 mm, so that in the process of use, generally, only the external surface needs to be cleaned and inspected, and no other maintenance is required.