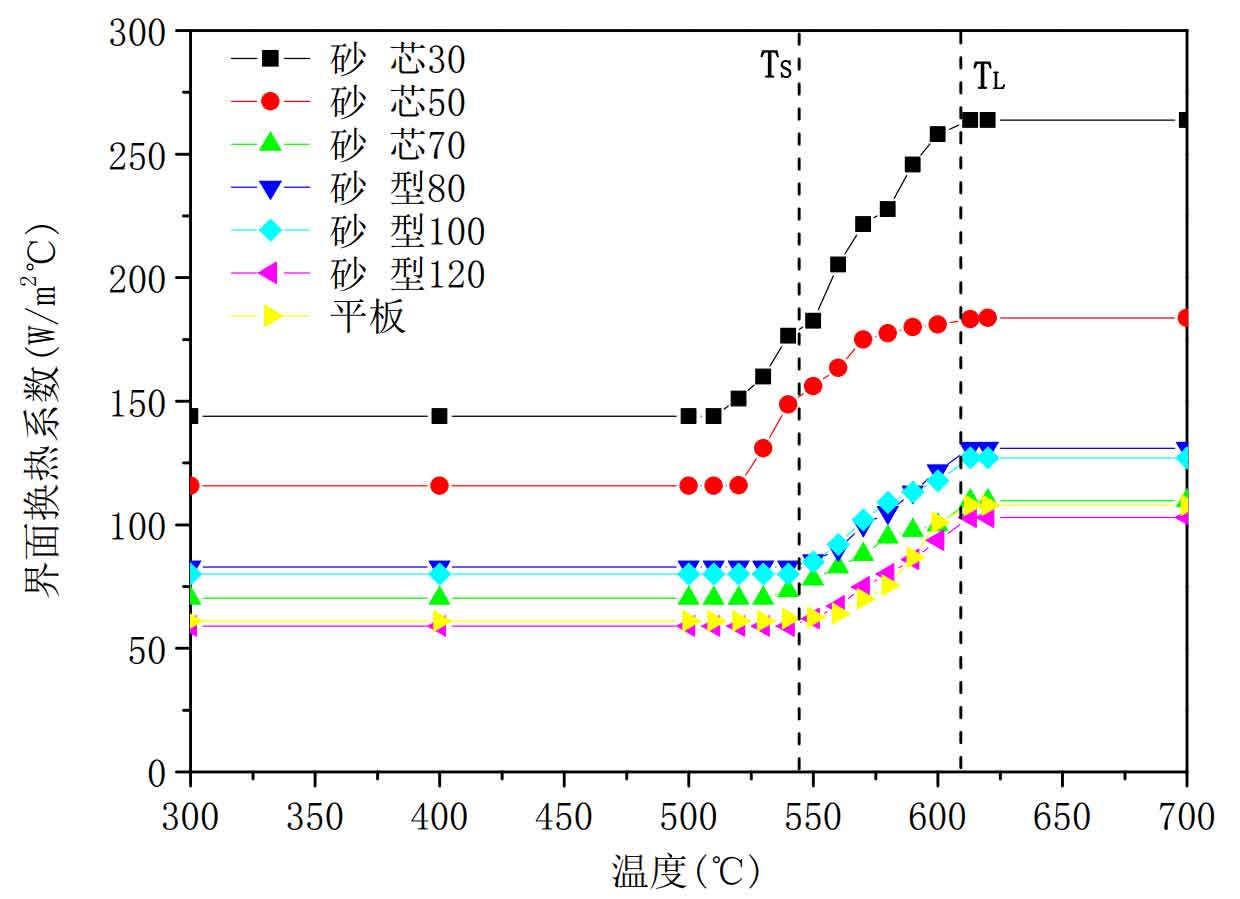

The change of interfacial heat transfer coefficient with time obtained by back calculation can only be used to determine the relative influence of different parameters on the behavior of interfacial heat transfer coefficient, which is not intuitive enough to reflect the change of interfacial heat transfer coefficient with the temperature of solidification process; We need to convert the interface heat transfer coefficient into a curve about the interface temperature of sand mold castings. After inversely calculating the change curve of interface heat transfer coefficient with time, we use time as a common reference to establish the piecewise functional relationship between interface heat transfer coefficient and interface temperature of sand mold castings, The unstable interface heat transfer coefficient obtained from the initial back calculation is regarded as the constant liquidus peak interface heat transfer coefficient, and the value of the stable point temperature point is fitted, as shown in the figure. In multiple groups of experiments, the back calculated interface heat transfer coefficient changes with the interface temperature of sand mold casting.

It can be seen from the figure that the change of interface heat transfer coefficient between ring sand mold casting and flat sand mold casting with temperature is mainly concentrated in the temperature range of solid-liquid phase, showing a form similar to “s” curve. The change of this range is mainly due to the solidification process of liquid metal in this range, resulting in the change of volume of sand mold casting, The form of interface contact changes from complete contact to incomplete contact, and an interface gap layer is formed, which gradually reduces the interface heat transfer coefficient.

As shown in the figure, the high temperature zone and low temperature zone of flat sand mold casting are the maximum and minimum values of interfacial heat transfer coefficient, which are 108 w / (M2 ·℃) and 61 w / (M2 ·℃), respectively. Within the range of liquidus and solidus, the interfacial heat transfer coefficient decreases with the decrease of sand mold temperature and presents an approximate “s” curve. Because the freedom of cooling shrinkage of annular sand mold castings is not as good as that of flat sand mold castings, and the gap between castings / molds is small, the maximum and minimum heat transfer coefficients of annular castings / sand molds increase with the decrease of outer diameter of annular sand mold castings, The maximum and minimum values of heat transfer coefficient at the interface between annular casting and sand mold with the smallest outer radius (80mm) are 131W / (M2 ·℃) and 83w / (M2 ·℃), respectively. The overall change trend is similar to that of flat sand mold casting; The sand core of the annular sand mold casting expands when heated and the casting shrinks when cooled. Therefore, the heat transfer coefficient of the sand core interface in the annular sand mold casting increases with the decrease of the inner diameter. The smaller the inner diameter of the sand mold casting, the more obvious the increase is. The minimum inner diameter is 30mm, and the maximum and minimum values of the heat transfer coefficient of the annular casting / sand core interface are 263w / (M2 ·℃) and 144W / (M2 ·℃) respectively; The “s” curve can reflect the change trend of interface heat transfer coefficient with the surface temperature of sand mold casting. With the obstruction of solidification shrinkage of sand mold casting and the extension of heating time of sand core, the maximum and minimum values of interface heat transfer coefficient increase, and the “s” curve extends to the direction of solidus.

We can also see from the figure that for a group of ring sand mold castings, the heat transfer coefficient of the inner core interface is always greater than that of the outer sand mold interface. With the increase of the size of ring sand mold castings, the heat transfer coefficient of the inner and outer interfaces will decrease as a whole, but the change law is basically the same. Through the change of interface heat transfer coefficient in solid and liquidus temperature, it can be found that the interface heat transfer coefficient of sand core is more obviously affected by geometry than that of sand mold, while the change of interface heat transfer coefficient between flat sand mold casting and sand mold is closer to the value and change trend of outer sand mold of ring sand mold casting, which is mainly caused by the heat transfer difference caused by the different structure and position of sand mold and sand core.