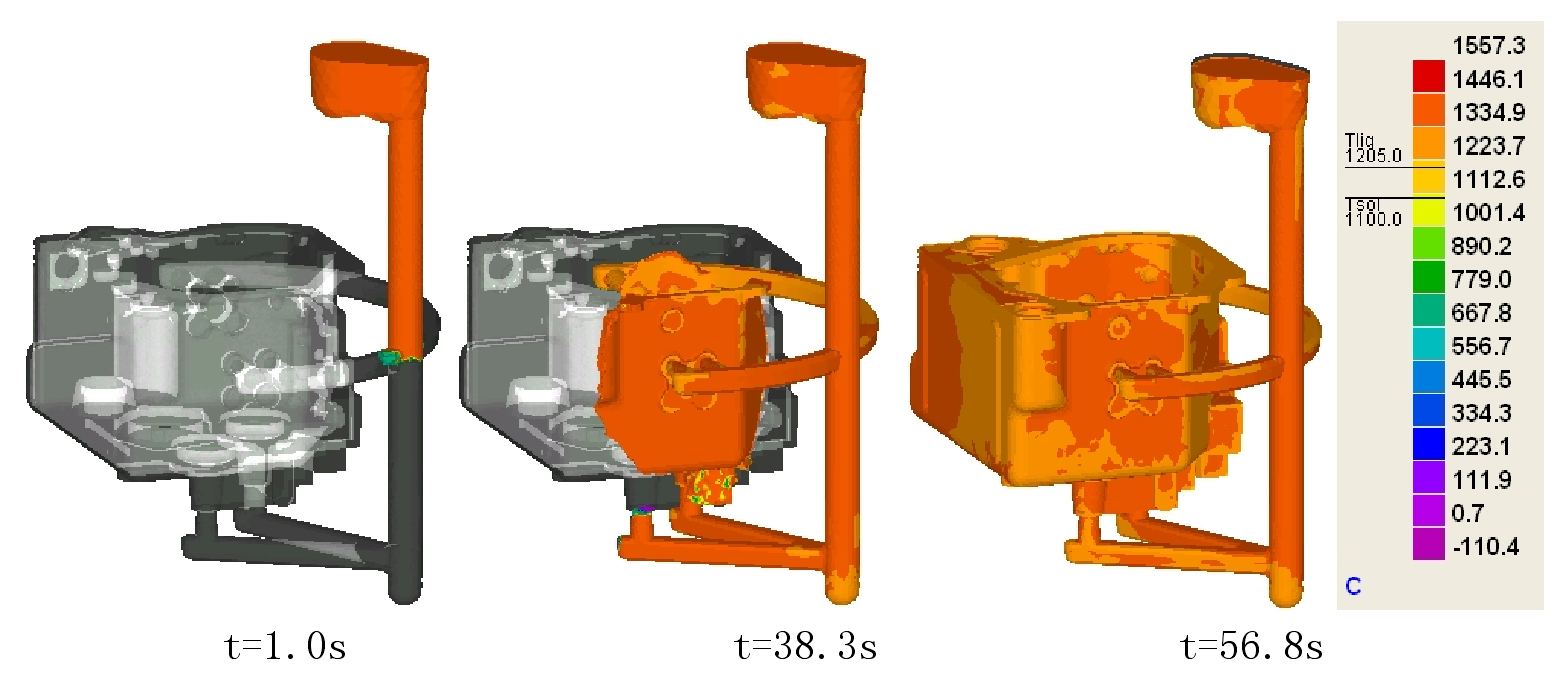

1. Mold filling simulation process and analysis

Figure 1 shows the filling state of the new process numerical simulation at different times. At 1 s, the molten metal is poured into the runner hollow ceramic tube part by the gate cup. Because of the hollow foam pattern, the filling resistance is small and the filling speed is fast. At 38.3 s, the gating system is basically full. It takes a long time and the speed is slow. It can be seen that at this time, the upper ingate has injected liquid metal into the upper half of the box, and the temperature of the liquid metal is above the liquidus, so the metal fluidity is good. Setting the position of the ingate here is conducive to reducing the shrinkage and shrinkage casting defects at the flange of the upper half of the box. At 56.8 s, the mold filling of the main body of the casting is basically completed, the distribution of temperature field is reasonable, and the fluidity is good. There are no obvious problems such as impact and splash in the whole mold filling process, and the mold filling is relatively stable. However, compared with the original process, the mold filling time is 22 s longer, indicating that the design of gating system needs to be further optimized.

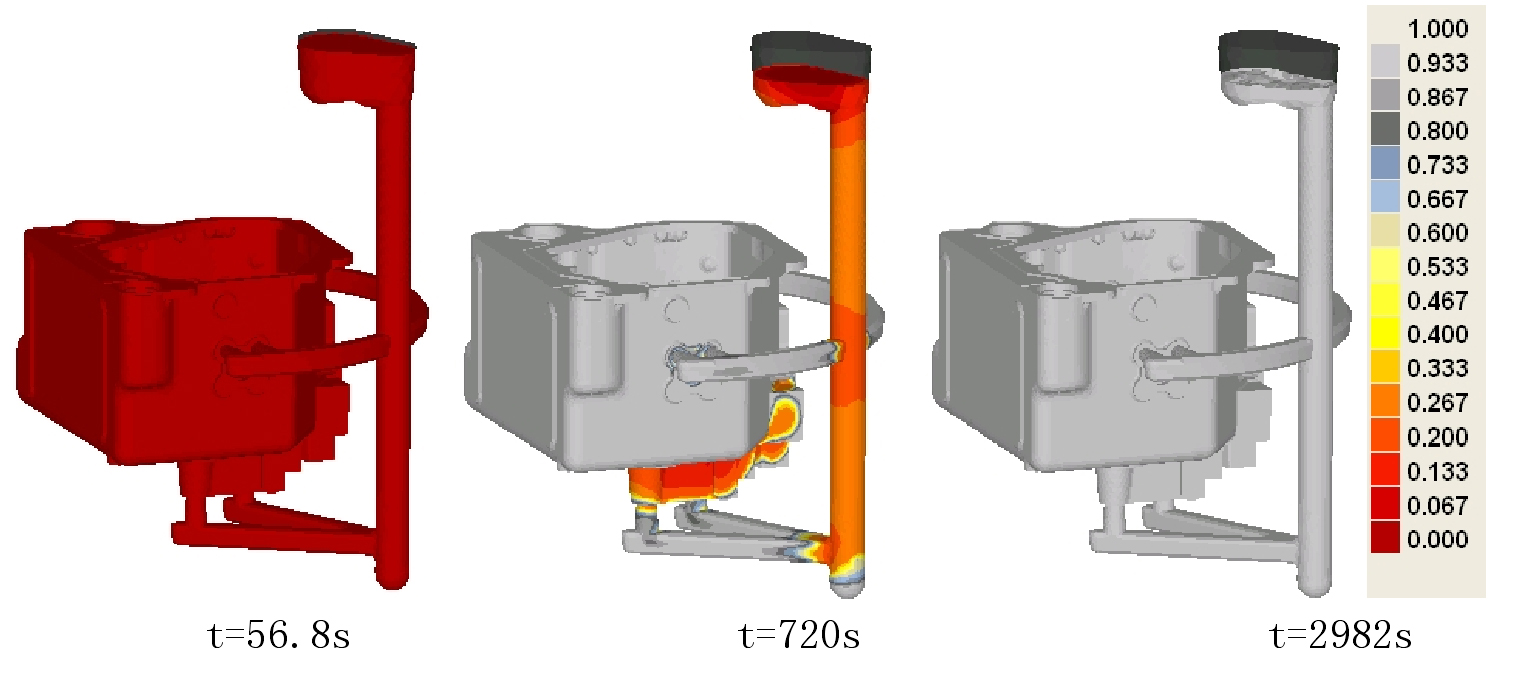

2. Solidification simulation process and analysis

The state of the casting solidification process is shown in Figure 2. It can be seen from the figure that the casting begins to enter the solidification state when t = 56.8s, and basically solidifies around the casting when t = 720s. Because the periphery of the casting is thin, it solidifies first. Since the position of the bottom inner gate is directly set at the thick part in the new process scheme I, there are relatively few non solidified parts at the bottom of the box compared with the original process, which is conducive to reducing the occurrence of shrinkage casting defects. However, due to the small sprue size of new process scheme I, when the bottom transverse sprue and inner sprue are basically solidified, the thick part at the bottom of the box is still not solidified, and the feeding effect of the gating system is not obvious, so the sprue size still needs to be improved. When t = 2982, the casting and sprue are basically completely solidified, and the solidification time is reduced compared with the original process.

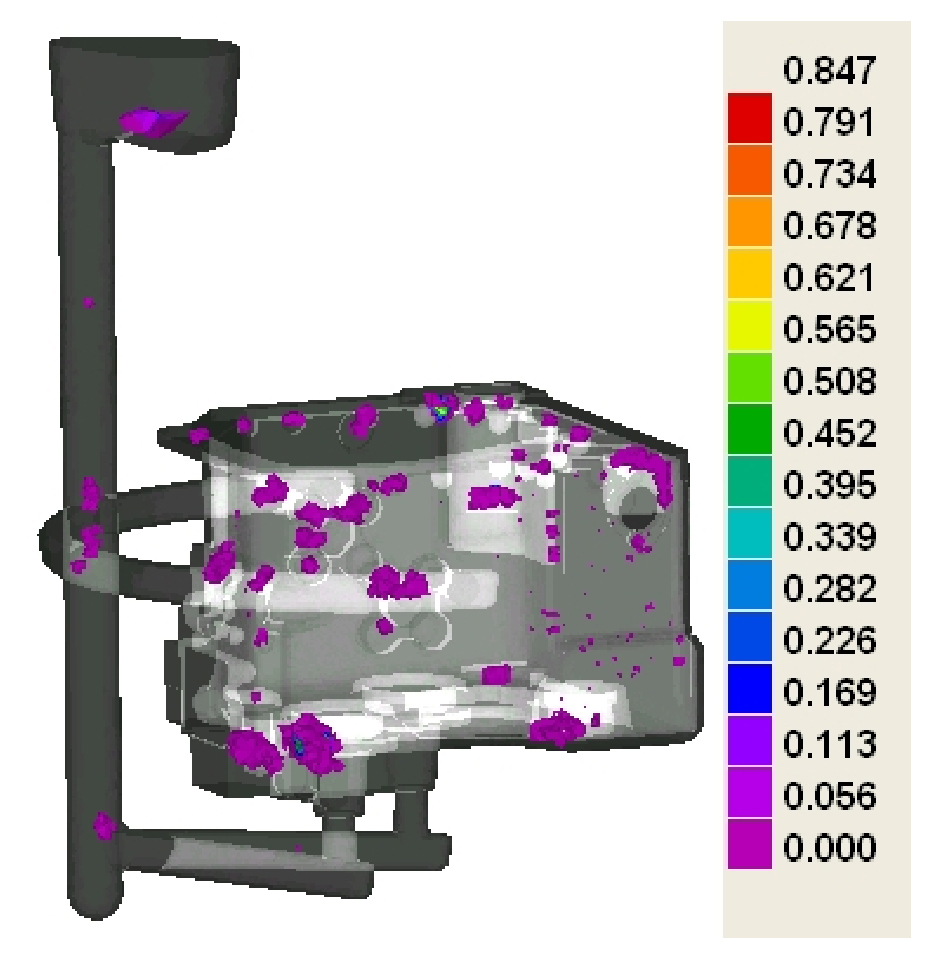

3. Analysis of casting porosity and shrinkage cavity defects

As shown in Figure 3, the maximum shrinkage rate of the improved gating system is 0.847, which is 1.7% lower than that of the original process, indicating that setting the inner gate directly at the thick part at the bottom of the box can reduce the amount of shrinkage and shrinkage casting defect holes; The total number of shrinkage cavity casting defects after improvement is 110.82cc, which is reduced by 16% compared with the original process, indicating that setting the inner gate on both sides of the upper half of the box can also reduce the amount of shrinkage cavity. Therefore, the step design of the gating system of the new process is correct. However, although compared with the original process, the effect is not obvious. Therefore, on the basis of the new process scheme I, it needs to be improved to further reduce the maximum shrinkage rate and the total shrinkage.