Pouring temperature, shell preheating temperature, investment casting pouring speed and other process parameters are very important to the molding quality of castings. According to the melting point of stainless steel and the characteristics of gating system, the pouring temperatures are set as 1500 ℃, 1530 ℃, 1550 ℃, 1580 ℃ and 1600 ℃; Shell preheating temperature is 620 ℃, 640 ℃, 680 ℃ and 700 ℃; The corresponding pouring speed is 30mm / s and 40mm / s.

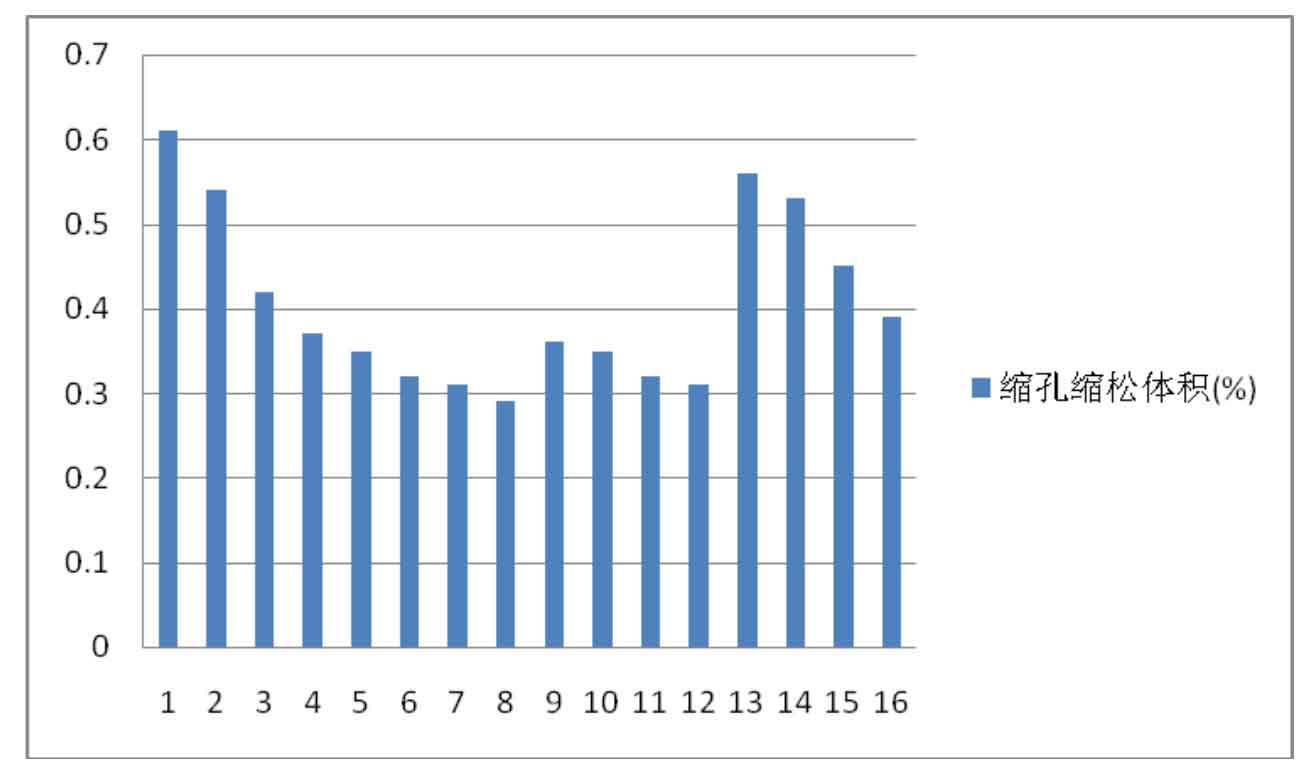

Because there is a certain matching relationship between process parameters, it is not necessary to do a comprehensive matching experiment, so it is necessary to design the experiment with a reasonable method. Firstly, the effects of different pouring temperature and shell preheating temperature on the molding quality of investment castings were investigated by single factor and multi-level experiments; Then 16 groups of multi factor horizontal orthogonal tests were designed to obtain the best combination of process parameters according to the prediction of shrinkage cavity casting defects.

| Factor | Pouring temperature / ℃ | Shell preheating temperature / ℃ | Pouring speed / (mm / s) |

| 1 | 1530 | 620 | 40 |

| 2 | 1550 | 640 | 40 |

| 3 | 1580 | 680 | 30 |

| 4 | 1600 | 700 | 30 |

Pouring temperature and shell preheating temperature have a great impact on the casting quality of castings. Based on the principle of slow pouring at high temperature and fast pouring at low temperature, a three factor horizontal orthogonal experiment with pouring temperature, shell preheating temperature and pouring speed as variables is designed, as shown in Table.

It can be seen from Figure that test 8 produced the least casting defects, and the shrinkage cavity and porosity casting defects accounted for 2.9% of the casting volume. The process parameters are pouring temperature 1550 ℃, shell preheating temperature 700 ℃ and pouring speed 30mm / s.