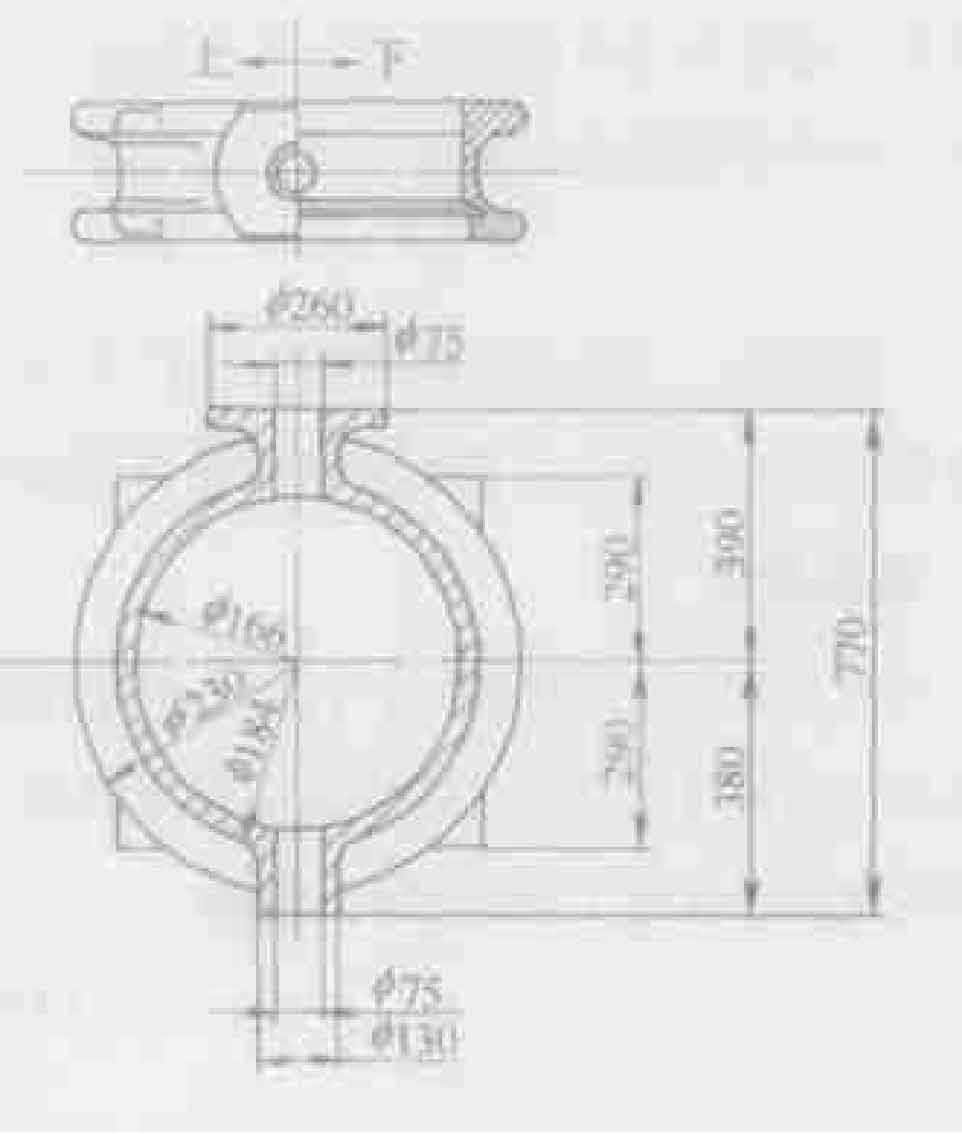

ZHY casting produced a batch of 500mm ductile iron valve castings for an enterprise in Japan. The valve is composed of valve body and valve plate. The outline dimension of the valve body is 770mm × 699mm × The pouring weight is 20350mm (see the following figure, the maximum wall thickness is 360mm). The valve body is required to be made of fcd45, which is equivalent to China QT450-10, and the strength of 25mmm Y-shaped test block is required σ b >450MPa , σ 0.2 >310MPa , δ> 10%, hardness 143 ~ 217hb. The metallographic structure and matrix shall be ferritic iron + a small amount of pearlite, and the graphitization rate shall be greater than grade 3. This is difficult for ductile iron castings, especially for large ductile iron castings. Quality requirements: the casting surface shall be smooth and flat without any defects. The products shall be accepted according to JIS Japanese standards. The requirements for dimensional accuracy, appearance quality, internal cleanliness and metallurgical quality are very strict, and ultrasonic flaw detection is carried out.

ZHY casting is more than 1000 500mm ductile iron valve castings produced in Japan, which have met the acceptance standards of Japan. The results are shown in the table below.

| Number | C | Si | Mn | P | S | ∑RE | Mg | σb/MPa | δ(%) | HBS | Graphite morphology (grade) | Pearlite (%) | Spheroidization rate (grade) |

| 1 | 3.65 | 2.56 | 0.39 | 0.035 | 0.011 | 0.035 | 0.045 | 466 | 19 | 191 | Level 6 | 10-15 | 3 |

| 2 | 3.67 | 2.68 | 0.41 | 0.034 | 0.018 | 0.043 | 0.045 | 472 | 18 | 164 | Level 6 | 10 | 2-3 |

| 3 | 3.53 | 2.64 | 0.37 | 0.037 | 0.016 | 0.034 | 0.054 | 465 | 20 | 161 | Level 6 | 5 | 3 |

| 4 | 3.62 | 2.67 | 0.38 | 0.040 | 0.013 | 0.029 | 0.039 | 459 | 18.5 | 168 | Level 6 | 5 | 2-3 |

| 5 | 3.64 | 2.61 | 0.39 | 0.040 | 0.009 | 0.031 | 0,042 | 461 | 17 | 173 | Level 6 | 8 | 3 |

At the beginning of the test, it was found that the strength and elongation of the single cast test block were relatively high, and the metallographic structure was also good, but the metallographic structure of the nodular cast iron valve casting body was unqualified. There was a large difference between the upper and lower boxes of some parts. The lower spheroidization rate was grade 2 ~ 3, while the body was only grade 5, resulting in the scrapping of the nodular cast iron valve casting.

Analyze the causes of the problems as follows:

(1) The lower surface spheroidization is inconsistent, which is mainly the result of spheroidization decline. The effects are: too high carbon equivalent, too high pouring temperature, slow cooling speed and so on. In addition, the sulfur content of molten iron is high, and the residual rare earth magnesium content is also high, which forms a thick layer of slag inclusion on the upper surface, which seriously affects the spheroidization effect. It is found from the observation that the thickness of slag inclusion layer is up to 2 ~ 5mm.

(2) There is a big difference between the test block and the body, which is mainly due to the large amount of pig iron in the batching and the high pouring temperature, resulting in the slow cooling speed and the decline of graphite.

According to the above analysis, we control CE = 4.2% ~ 4.4%, increase desulfurization measures, increase the amount of scrap (scrap from 20% to 30%), increase carbon in the furnace, reduce the treatment temperature and pouring temperature, change the treatment temperature to 1410 ~ 1430 ℃ and pouring temperature to 1320 ~ 1340 ℃, so as to eliminate the above problems, The structure of nodular cast iron valve casting body is consistent with the test block.