1. Design of formwork thickness

The following contents shall be considered in the design of formwork:

(1) the mold shell shall have sufficient strength and rigidity to avoid deformation and cracking of the mold shell during iron shot filling.

(2) the mold shell can quickly transfer heat to the filled iron shot during pouring, so as to achieve the cooling effect required by the casting process design. At the same time, it should have the ability of heat storage and insulation for the feeding riser and gating system.

(3) reasonable production and operation cost.

S1100 diesel engine crankshaft mold shell thickness design: the casting part is selected as 6-8mm for enhanced chilling, and the pouring riser and sprue part is selected as 12-14mm for enhanced thermal insulation.

2. Ensure that the iron shot is filled

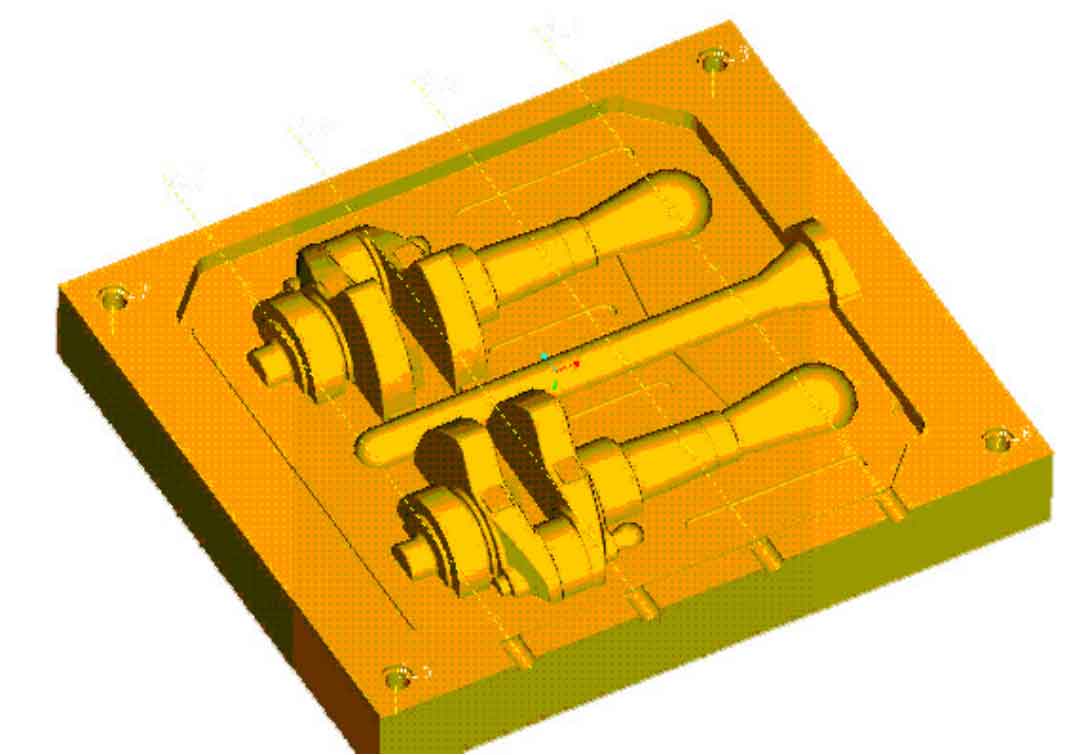

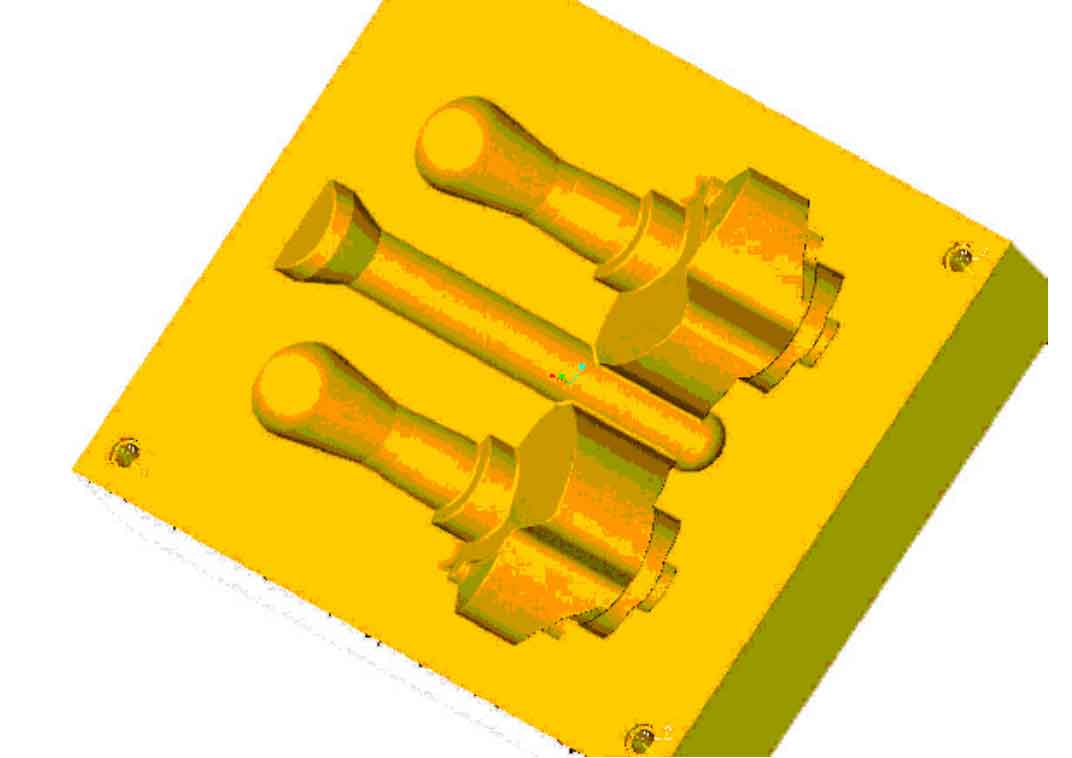

In the analysis of the vertical iron shot filling of the crankshaft mold shell of S1100 diesel engine, it is found that it is difficult to fill the iron shot in the groove between the two plates of the crankshaft (the gap is only 16-18mm) (see Figure 1 below), resulting in the deformation of the mold shell (shrinkage cavity) and molten iron leakage during pouring. Therefore, the mold shell between the two plates of the crankshaft is made into a whole. See Figure 2 below.

3. Exhaust

During pouring, the coated sand shell mold and oil plug hole clay core will produce a large amount of gas, causing shrinkage porosity, shrinkage cavity and surface porosity casting defects. Therefore, it is very necessary for the mold to exhaust smoothly. An air passage connected with the atmosphere shall be set at the oil plug hole clay core head and concealed riser in this test.