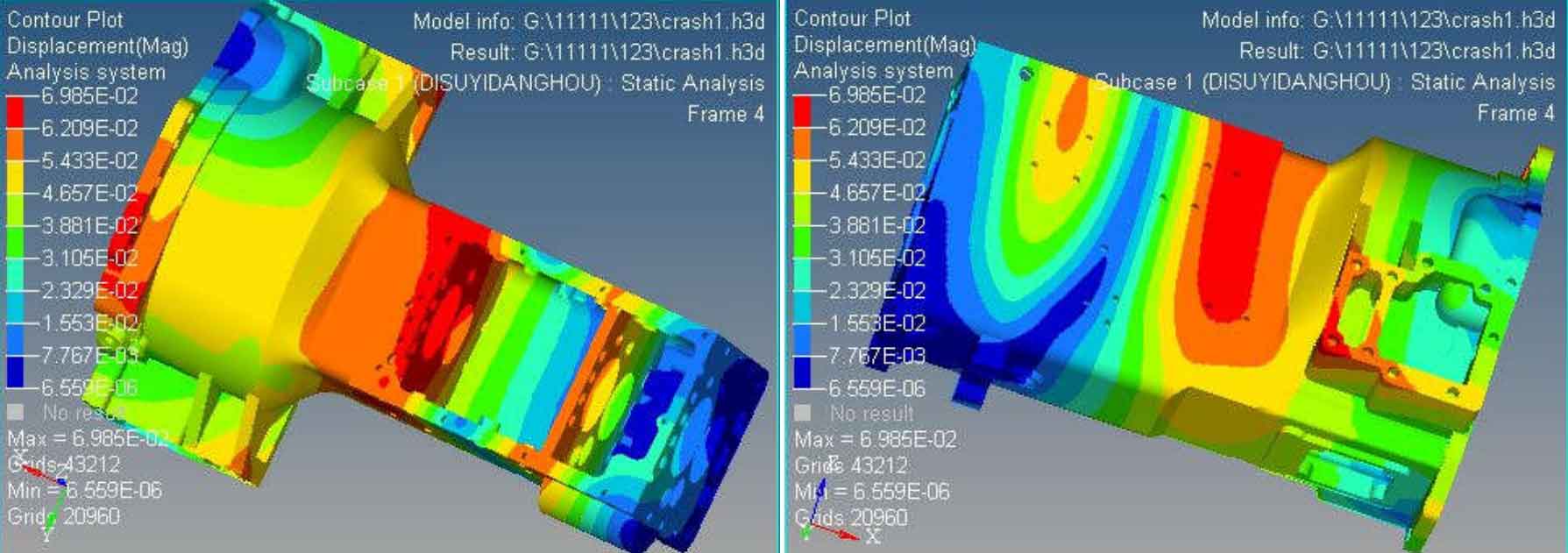

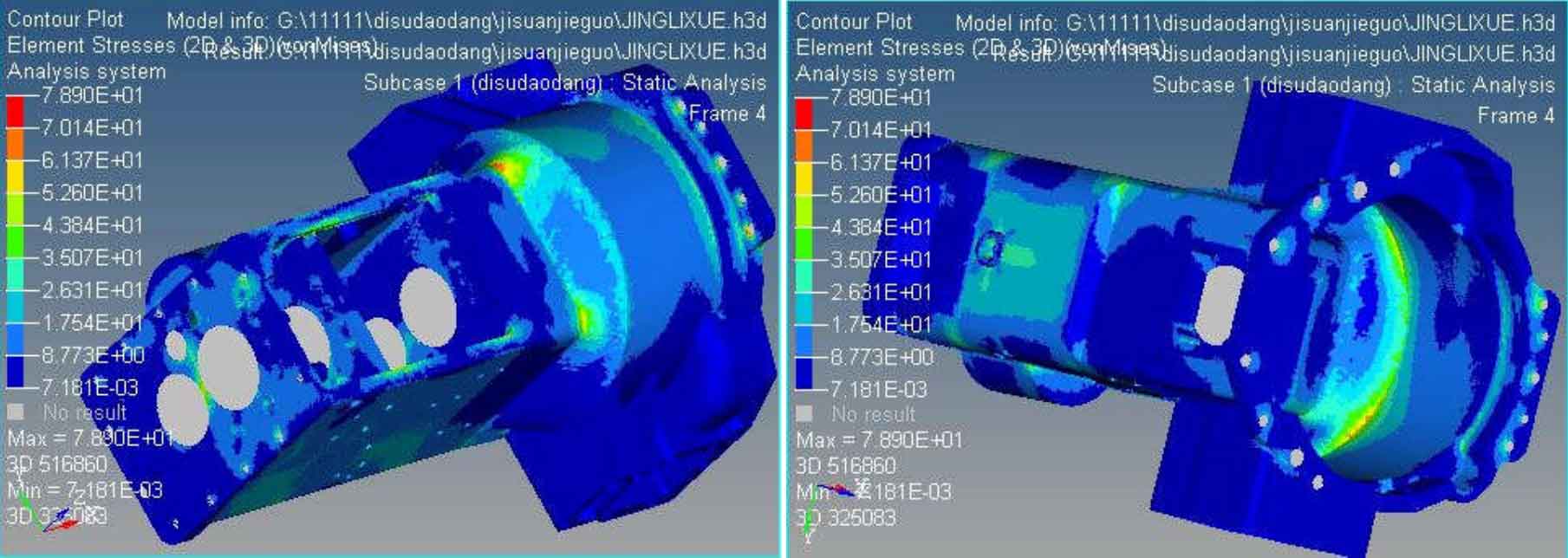

Fig. 1 and Fig. 2 are displacement nephogram and stress nephogram of tractor gearbox housing casting under reverse working condition respectively.

From the displacement cloud chart 1, it can be found that the deformation part under reverse gear condition is basically the same as that under first gear condition. The difference is mainly the deformation direction and amount. There are three main positions: position 1 is the connecting part between the casting of tractor gearbox housing and engine, and the connecting surface is torsional deformed; The second position is the connecting part between the casting of the tractor gearbox and the rear axle, which also has torsional deformation; Position 3 is the position of the middle diaphragm. The deformation at this position is the largest, which is about 0.070mm.

From the stress cloud Figure 2, it can be found that the stress distribution is relatively regular, mainly distributed around the three diaphragm positions, as well as the curved surface of the front part of the casting of the tractor gearbox shell. Among them, the maximum stress appears near the middle diaphragm, which is about 78.9mpa, which is less than the allowable stress of the material 124mpa.

To sum up, considering that the total mass of the casting of the tractor gearbox shell is about 164.8kg and the mass is very large, it can be considered to reduce the wall thickness of the shell where the stress is small under the condition that the shell meets the normal service performance, so as to reduce the material consumption.