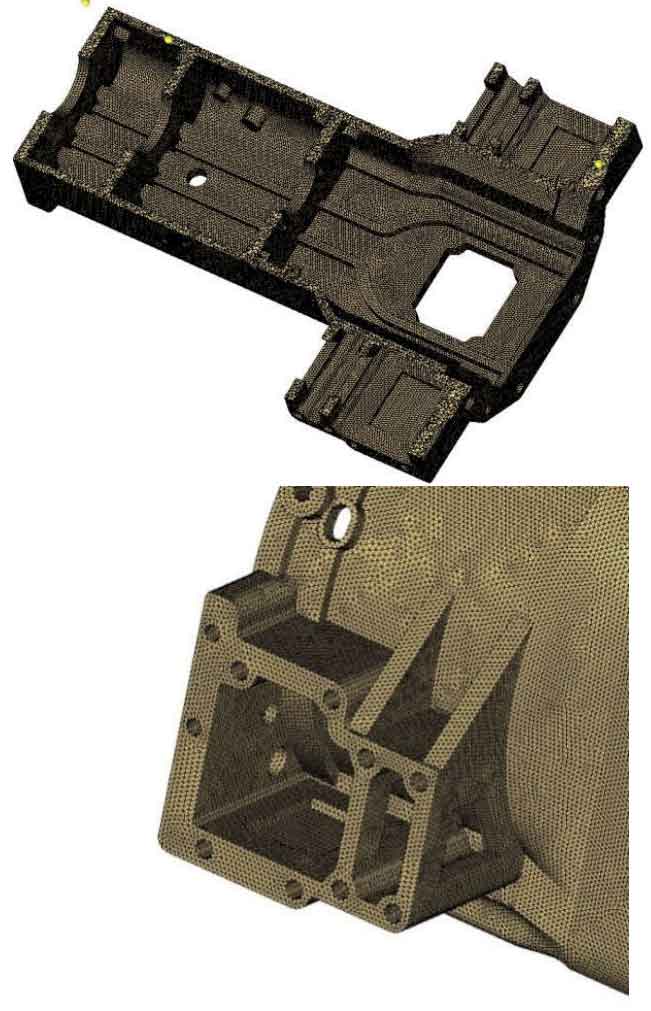

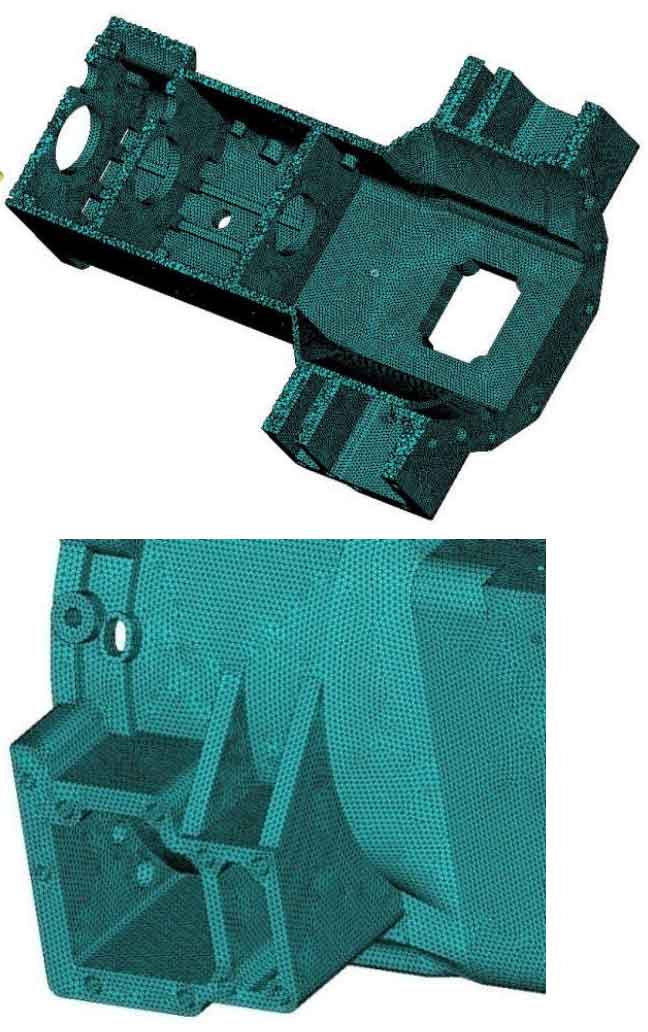

According to the topology optimization calculation results, the casting mechanism of the original tractor gearbox shell is optimized and improved according to the principle of increasing the wall thickness or setting stiffeners in the red area and reducing the wall thickness or hollowing out in the blue area. The structure of the improved gearbox housing is shown in Figure 1. Compared with the casting structure of the original tractor gearbox housing as shown in Figure 2, the improved design is mainly in the following aspects:

(1). Reduce the wall thickness of the inner cavity at the front and lower part of the tractor gearbox shell casting, and arrange the stiffeners connected with the inner cavity at the middle and rear in the original structure of the gearbox in the thinned area;

(2). Slotting and thinning the double ears on both sides of the gearbox;

(3). Set transition fillets at the parts with relatively concentrated stress to reduce stress concentration;

(4). Reduce the thickness of non working face.

To sum up, the improved design of tractor gearbox shell casting is completed. The weight of the improved box is 148.4kg, which is reduced by 16.4kg from the original 164.8kg, with an overall reduction of about 9.95%. In order to ensure that the improved structure meets the requirements, the strength and stiffness of the improved structure need to be verified later.