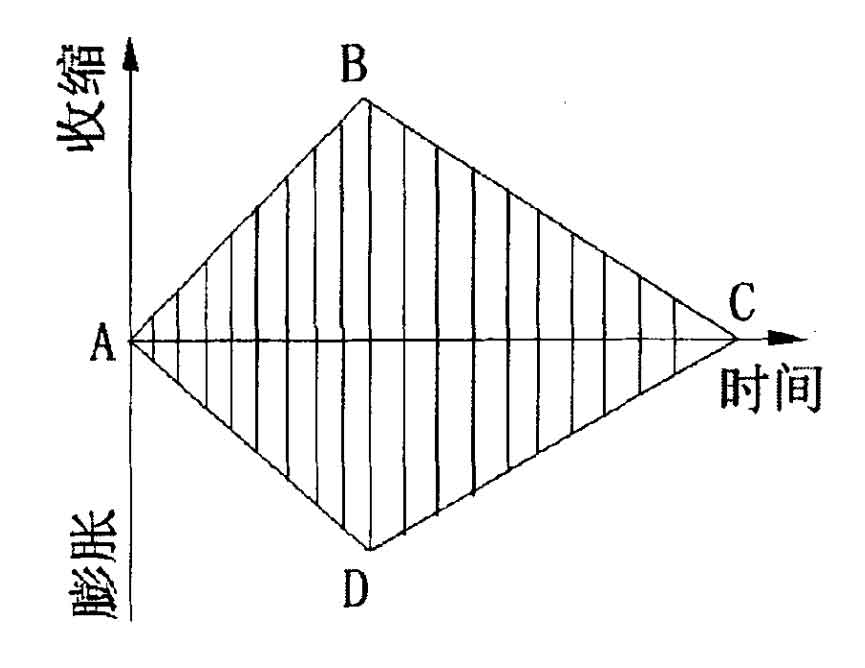

The physical model of complete superposition of equilibrium solidification expansion and shrinkage is to imagine a cast iron alloy composition, and its total shrinkage is equal to the total graphitization expansion. If the shrinkage and expansion per unit time can be controlled in the ratio of 1:1 from beginning to end, the cast iron will not produce volume loss and surplus utilization at any time, and the graphitization expansion is 100% utilized, as shown in Figure 1. The expansion and contraction of balanced solidification are completely superimposed, and the iron castings can not use risers, which will neither produce shrinkage cavity and porosity, nor expand the cavity. This proportional expansion and contraction mode is the physical model of equilibrium solidification.

The ideal equilibrium solidification is difficult to achieve, but the actual iron castings will still have good self feeding. This is because in general engineering, the measurement of cooling curve is only the cooling condition at the measured point ~ and cannot represent the whole cast iron. In other words, at a certain time in the solidification process, part of the cast iron is shrinking, and the adjacent parts may have entered graphitization expansion. The shrinkage and expansion are carried out at the same time, while the molten iron is connected and can be supplied to each other. At this time, the shrinkage value of iron castings will become smaller when the expansion shrinkage superposition is offset, which is the net result of expansion shrinkage offset.

The reason why a cast iron can realize self feeding is based on two reasons: first, the cooling rate in different areas is different, the cooling rate in the thin-walled part is greater than that in the thick-walled part, and the cooling rate at the edges and corners of the cast iron is greater than that in the center; Secondly, for the cooling process of a certain point of iron castings, shrinkage first and then expansion, that is, there is the separation of shrinkage and expansion in time. For the cast iron as a whole, the time of shrinkage and expansion in each area is different, first and then, staggered and overlapped with each other. Therefore, the separation of expansion and contraction at the same point in time makes it possible for expansion and contraction complementarity between different points in space.

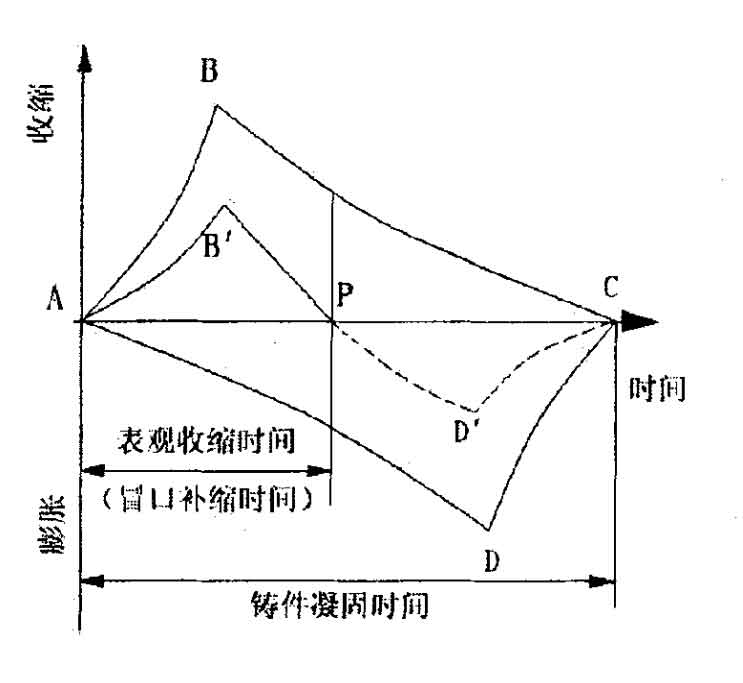

From Figure 2, it can be explained that different types of cast iron castings poured with the same alloy have different shrinkage values. For small iron castings, the heat dissipation speed is relatively fast, and the shrinkage (shrinkage speed) per unit time is large, that is, the shrinkage is concentrated, the graphitization expansion moves back relatively, and the apparent shrinkage increases. At this time, graphitization expansion can not play the role of feeding, and the external feeding of gating system or riser must be strengthened. On the contrary, for iron castings with large wall thickness, the average cooling speed is slow, the shrinkage speed is small, and the graphitization expansion is relatively early, which makes it easier to offset the expansion and contraction, move the equilibrium point forward, and shorten the apparent shrinkage time, that is, the feeding time of riser. To sum up, all factors that are conducive to the delay of shrinkage of cast iron and the advance of graphitization expansion will be conducive to the early superposition of expansion and shrinkage and the reduction of riser size. In addition, the utilization degree of graphitization expansion can be improved by improving the rigidity of the mold to reduce the expansion consumed by the outward movement of the mold wall, which is also conducive to the forward movement of the equilibrium point P and the reduction of the riser size. It can be seen that iron mold sand coated casting itself is a process method which is very conducive to the balanced solidification of nodular iron parts.

The shrinkage value of cast iron alloy is different from that of cast iron. The shrinkage value of cast iron is not a constant in material. Different chemical composition, casting structure and casting process conditions will have a direct impact on it. The shrinkage value of iron castings is measured by pouring samples. Because the sample is a special cast iron, and the actual cast iron has different sizes, shapes and structures. During solidification of iron castings, the actual cooling rate and temperature field distribution vary greatly, and the superposition of shrinkage and expansion in different parts at the same time will be affected, that is, the utilization degree of graphitization expansion will be affected. In this way, the differences in the degree of shrinkage and expansion and the time process of shrinkage and expansion lead to the phenomenon of different shrinkage values when casting different iron castings with the same alloy.