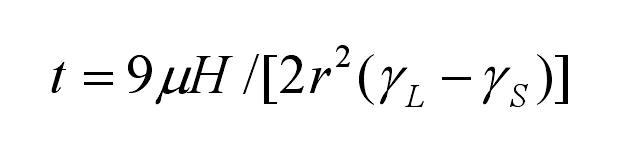

According to the state and velocity of the flowing high-temperature metal liquid after colliding with each other in the mold cavity, it can roughly describe whether the whole filling process will produce casting defects such as inclusion oxidation. When the flow rate of molten metal exceeds the critical rate of 0.35 ~ 0.5m/s, it is easy to produce oxidation impurities. If it is necessary to judge whether there are serious inclusions and casting defects in the casting, it is necessary to judge whether the parts that produce scum during solidification belong to non part positions, such as risers. The Stokes equation can be used to approximately calculate the floating time of inclusion casting defects:

Where: T – time (s), μ — Viscosity of liquid molecules (PA ● s), h, floating distance of inclusion casting defects, r-impurity radius, γ L – liquid metal weight (n / cm3), γ S – severity of inclusion casting defects (n / cm3).

When the floating time of inclusion casting defect is greater than the solidification time of liquid metal, the inclusion casting defect remains in the casting part.