Fig. 1 shows the temperature field changes of sand mold castings at 2S, 40s, 120s and 220s after the molten metal fills the mold cavity. It can be seen from Figure 1 (1) that the solidification sequence of molten metal in the mold cavity conforms to the principle of sequential solidification within the time when the sand mold casting is filled. Obvious feeding occurs at the riser, which plays a good role in feeding. From figures 1 (3) and (4), with the extension of solidification time, it can be observed that the temperature inside the sand mold casting is higher than that at the edge of the sand mold casting wall, but the temperature of the molten metal in the inner sprue and transverse sprue is always higher than that in the thick part of the sand mold casting. Until 220s after solidification, the sand mold casting basically solidifies, while the inner sprue still maintains the liquid-solid two-phase zone, which indicates that the gating system and riser system, It has a good effect on the solidification of sand mold castings. In conclusion, the solidification effect is better than the first and second schemes.

Fig. 2 shows the change of solid rate in the solidification stage of a single riser section by single side bottom injection. Within 20s after the solidification of sand mold casting, the temperature of molten metal in the inner gate is high, and a good temperature gradient is formed in both sections. In the range of 45-240s, according to the principle of compound sequential solidification of liquid metal solidification, the large part behind the liquid metal is fully fed, and the riser still feeds the thick part at the upper part of the cylinder head well. The inner gate feeds the thick part at the lower end of the cylinder head which is difficult to feed the riser in the first and second schemes, so that the whole sand mold casting does not form an obvious isolated liquid phase area.

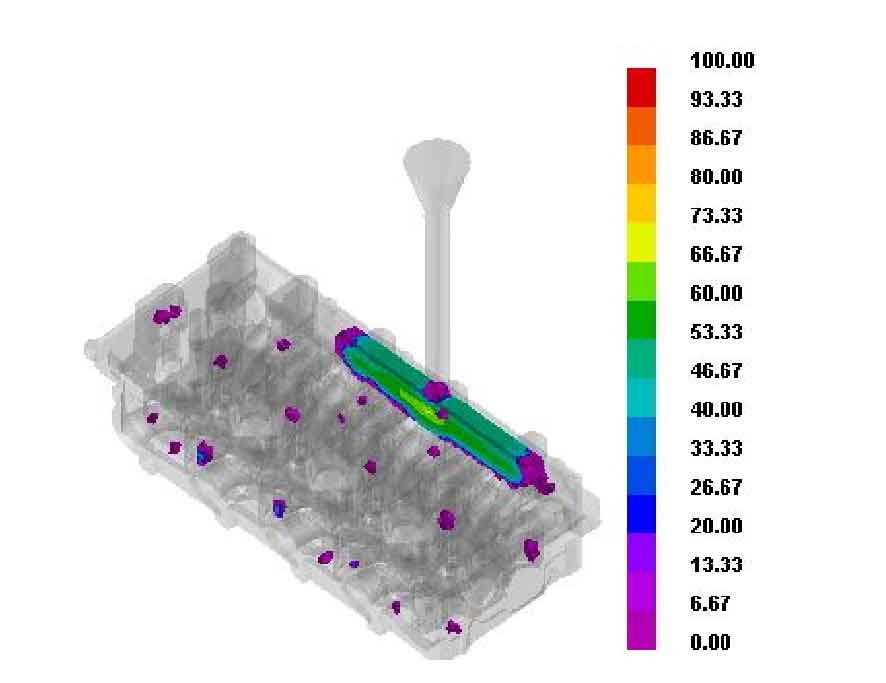

The position of shrinkage porosity and shrinkage cavity of sand mold casting of single side bottom injection gating system is shown in Figure 3. It can be seen from the figure that there is only uniform dispersion shrinkage porosity in the sand mold casting, and the quality of the sand mold casting is ideal.

The bottom pouring system can fill the cylinder head smoothly, and can meet the sequential solidification conditions along the riser and inner sprue in the solidification stage. After 240s of molten metal, no isolated liquid phase area is found, and only relatively dispersed shrinkage porosity is found after solidification. It can be seen that this process is better than the previous two schemes, which can be used in actual production.