The finite element analysis software is used to simulate the flow field and temperature field in the iron mold sand coating process of nodular cast iron crankshaft, and predict and analyze the possible defects, so as to evaluate and optimize the process before tooling trial production.

The modeling of iron mold sand coating process is different from others in that there is a layer of sand coating shell in the middle, so it is necessary to model the casting, sand shell and mold respectively. According to the part drawing, gating system drawing and upper and lower iron mold drawing given by the factory, the three parts are modeled and assembled by using three-dimensional modeling software, and the finite element mesh is divided by using the software.

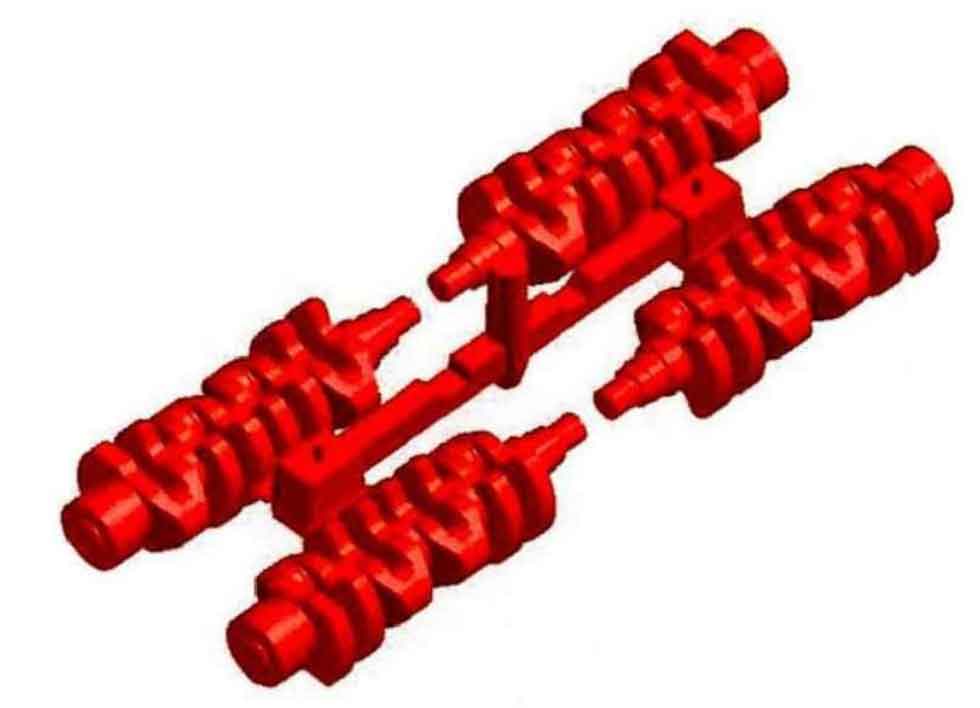

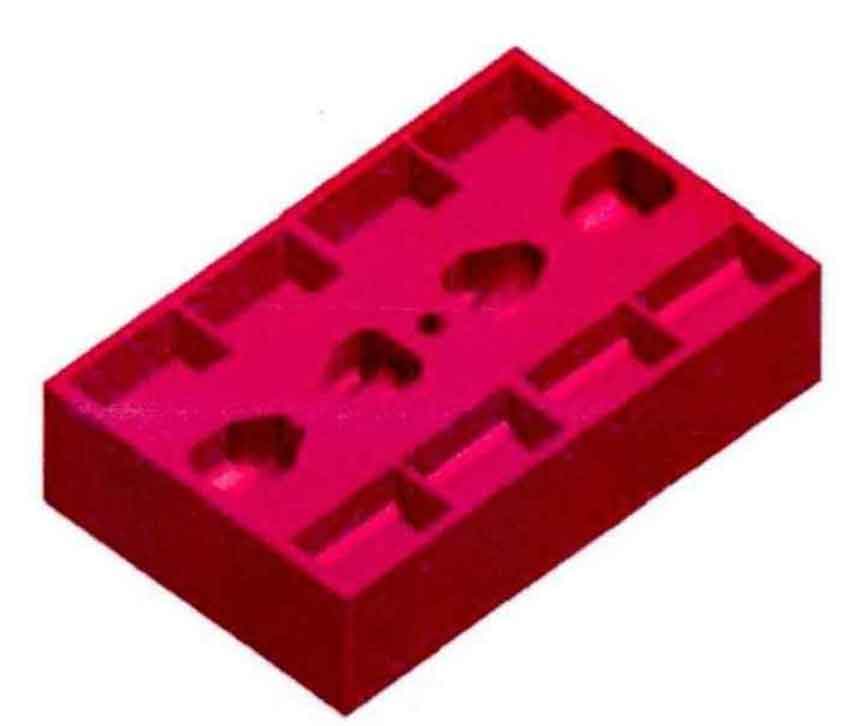

The dimensional drawings of crankshaft and gating system are obtained from the factory. The pouring method is top injection type, with four pieces in one box. The length of a single crankshaft is 464.91mm, and the maximum diameter is about 141mm. The straight bypass is 138mm high, and there is a transverse bypass symmetrically on both sides. There is a sand retaining groove in the front section of the transverse bypass, and the inner sprue at the end is connected with the middle part of the parting surface of the four crankshafts. The three-dimensional modeling of the casting is shown in Figure 1.

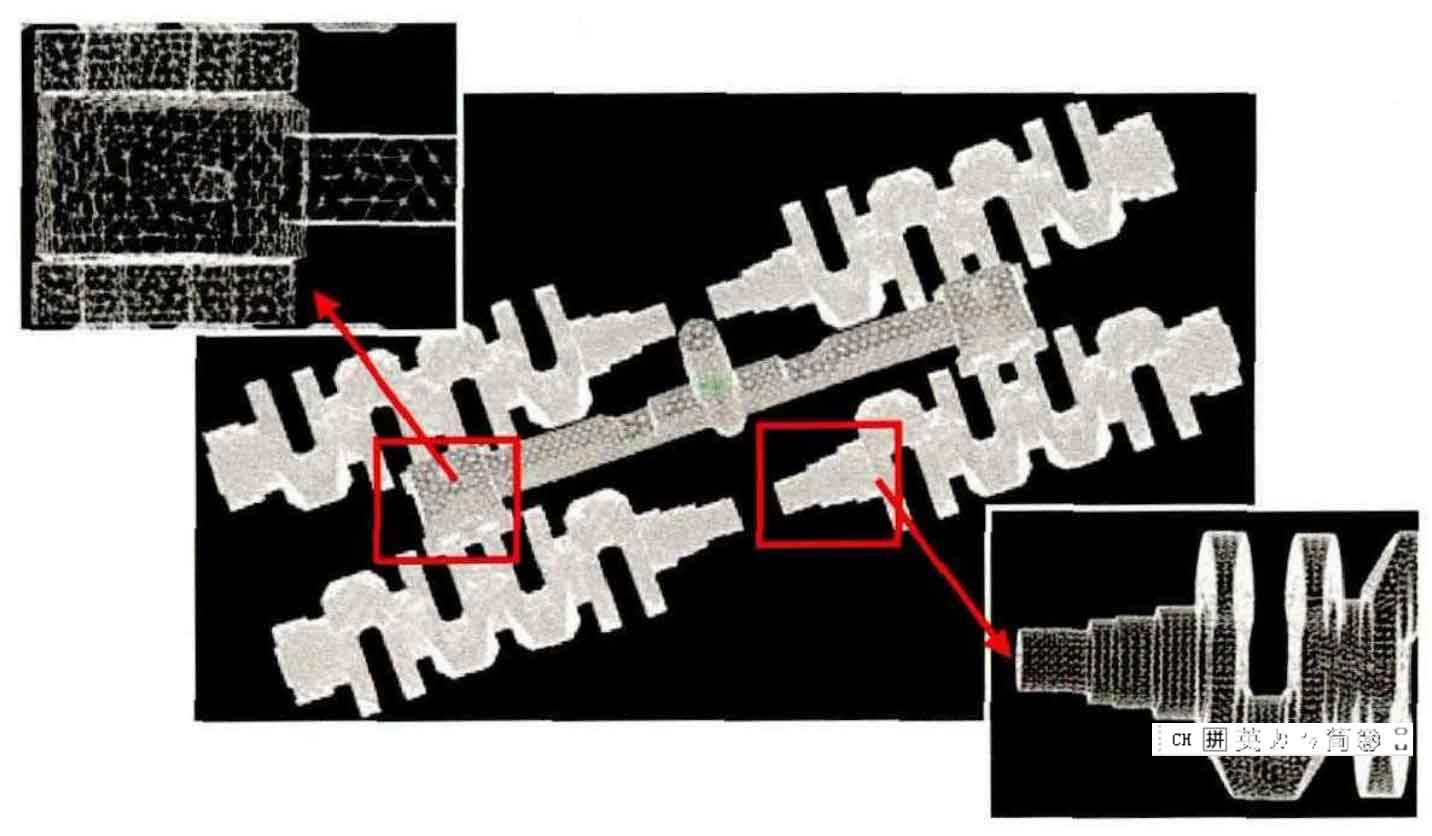

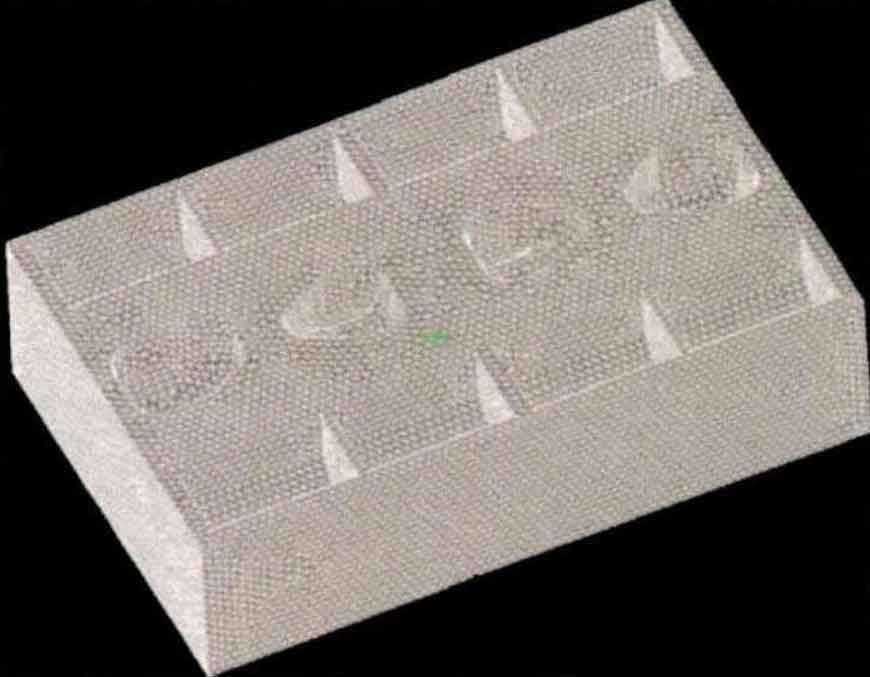

Divide the molded casting into finite element mesh. The crankshaft part needs to be calculated as accurately as possible, so the mesh length is 2mm. At the same time, in order to speed up the calculation speed, the mesh size of the gating system part is 5mm. First, the surface mesh is divided, and then the body mesh is divided. The grid is tetrahedron, with 49960 nodes and 99932 elements, as shown in Figure 2.

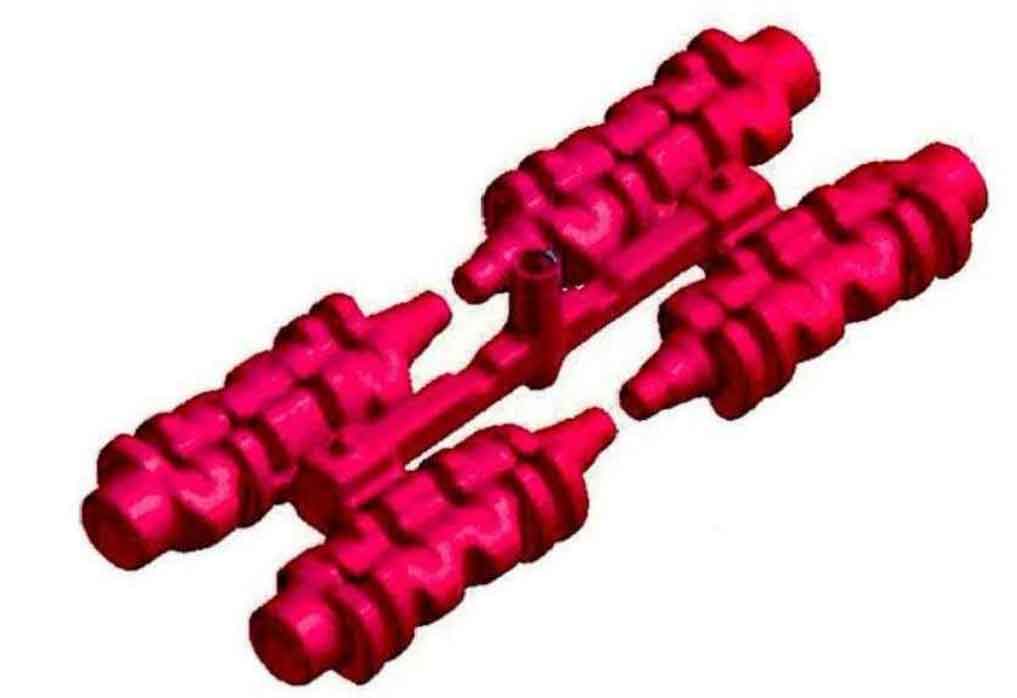

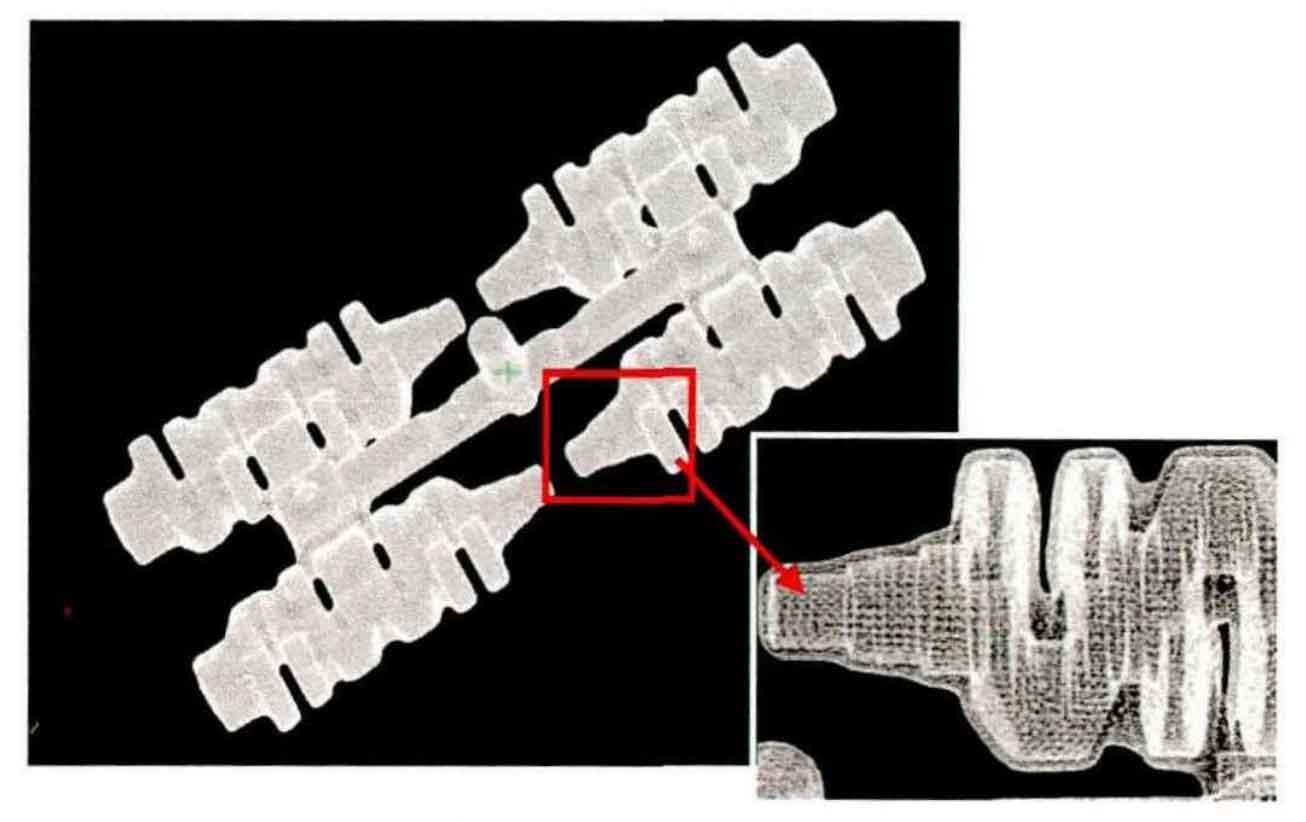

According to the existing process of the factory, the thickness of the coated sand shell is 6mm, and there are 10 sand shooting holes on each crankshaft to form a unified whole with the sand shell. The thickness of the metal mold varies along the shape of the crankshaft, and the thickness is between 25-30mm. The 3D model and finite element mesh are shown in Figure 3-6. There are 22285 nodes and 44566 units in the mold. There are 94192 nodes and 188424 units in the sand shell.