This part of the experiment was carried out just after the arrival of the ultrasonic equipment. The main purpose is to test the probe and preliminarily explore the effect of ultrasound. The molten iron used in the experiment has not been spheroidized.

(1) Ferroalloy probe

As soon as the ultrasonic equipment was obtained, an experimental experiment was carried out. The ferroalloy probe was used to act in the molten iron. After the ultrasonic equipment reported an error, the titanium alloy probe melted, which may be due to the low melting point of the component probe. Therefore, the use of ferroalloy probe in molten iron is abandoned.

(2) Non spheroidized molten iron, graphite probe

Through continuous attempts, adjust and improve the sand blasting process, heat the iron mold to about 275 ° C, and use nitrogen as pressure to spray coated sand into the iron mold. Start the following experiment.

The length of the graphite probe used in this experiment is the calculated value of 136mm, and the molten iron is not spheroidized. Fill the two cavities with molten iron successively, and put the probe into one cavity to apply ultrasonic wave and the other without ultrasonic wave. The ultrasonic action time is 12s, the output current changes from 2.0A at no-load to 0.3A, and the output power is 73%. The ultrasonic effect is not obvious. When the probe is taken out, the molten iron at the contact place is stuck on the probe and cannot be removed. The probe is invalid and cannot be used. The graphite probe generates heat when it is unloaded, and the output current displayed by the ultrasonic generator is large. It can be inferred that the graphite probe itself is used as a load rather than an ultrasonic medium, so the ultrasonic energy introduced into the molten iron is very small. Through analysis and discussion, the following reasons are obtained:

- Improper length of graphite probe;

- Improper graphite material;

- The link between graphite probe and ultrasonic horn is not tight.

(3) Change the length of graphite probe

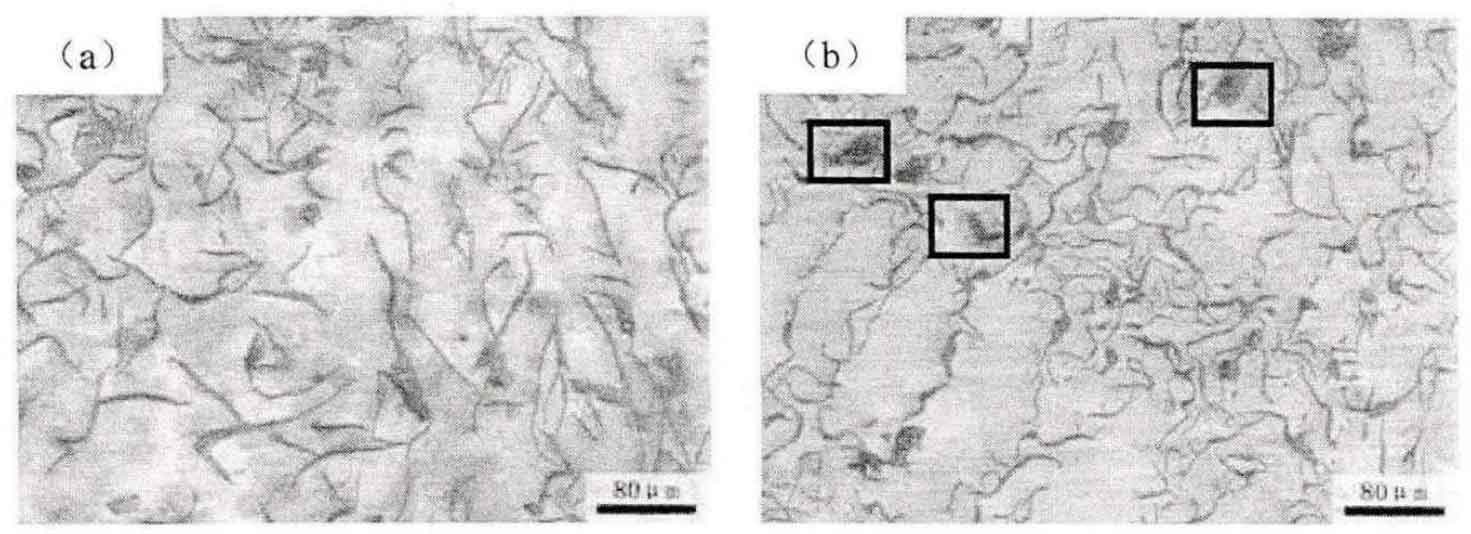

Redesign the length of graphite probe, replace the probe with 80mm and fasten it. The experimental process is as above, ultrasonic is applied for 12s, and the current is maintained at 2.5A. In this experiment, two gray iron castings without ultrasonic treatment and with ultrasonic treatment were sampled to observe the metallography. As shown in the figure:

It can be seen from the above figure that although the molten iron is not spheroidized, the effect of ultrasound on its structure can be seen. Figure (a) shows the specimen after ultrasonic treatment, and the overall structure is more uniform than that without ultrasonic treatment in figure (b); In addition, there is graphite with sharp corners (marked in the red box) in figure (b), which is easy to cause cracks in gray iron castings; By observing the morphology of vermicular graphite, it is found that the graphite in figure (a) is short and thick with a small number of dendrites, while the graphite in figure (a) is fine with many dendrites. The reason for such microstructure is that ultrasonic wave is generated near the probe, resulting in cavitation effect. The ultrasonic vibration also makes the temperature of the surrounding liquid drop slowly, and the undercooling is smaller than that without ultrasonic wave. Therefore, the dendrite grows slowly and forms short and thick graphite strips.