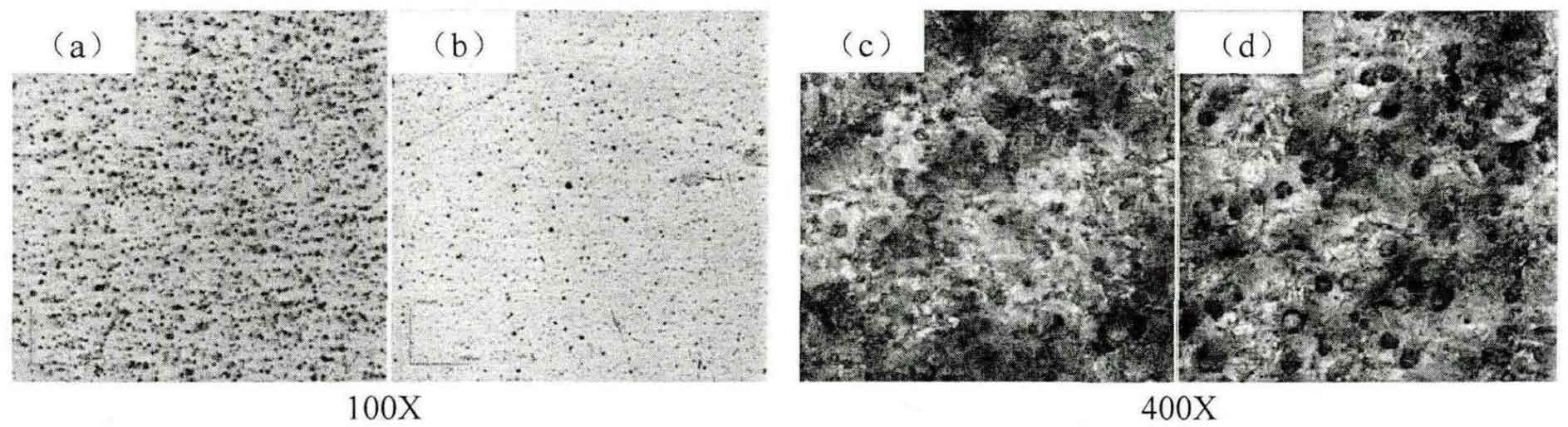

After spheroidizing, the experimental molten iron is poured into the mold, ultrasonic wave is applied to one of the cavities, graphite probe is used, the depth below the liquid level is 20mm, the action time is 15s, and the current is 1.5A. Take samples from the castings in this experiment to observe the metallographic phase, as shown in Figure 1.

It can be clearly observed from Figure 1 (a) and (b) that the number of graphite increases significantly after ultrasonic treatment; It can be observed from figures (c) and (d) that the graphite balls in figure (c) are smaller and the number of graphite balls is more than that in figure (d). The preliminary results show that ultrasound can refine the microstructure of nodular cast iron during solidification.

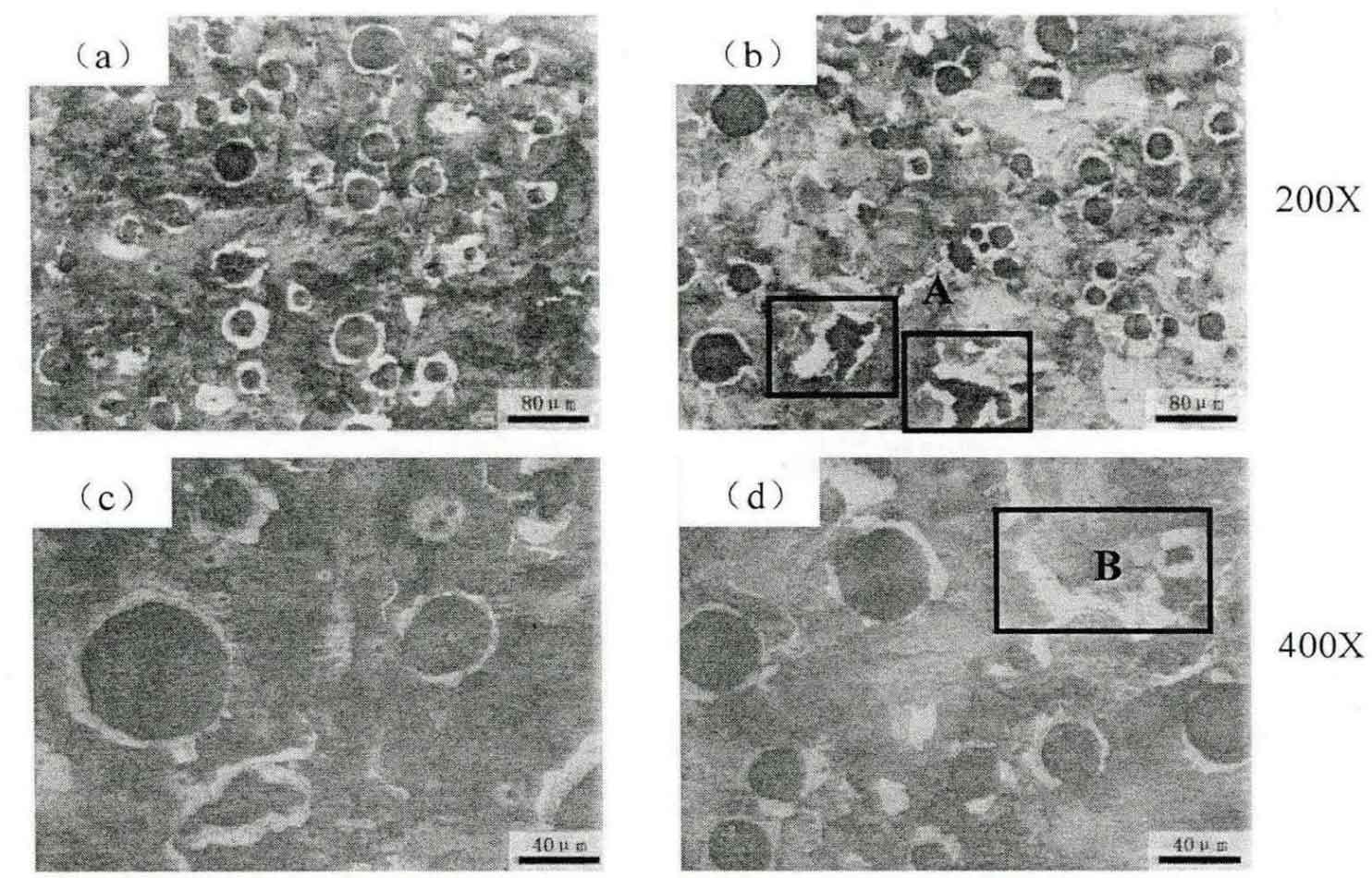

In order to further verify the effect of applying ultrasound during solidification, supplementary experiments were carried out. The experimental process is basically the same as that of the previous experiment. After the molten iron is spheroidized, it is poured into the mold, and the graphite probe is used to apply ultrasonic wave to the molten iron in one of the cavities. The probe goes deep 20 mm below the liquid level, but the experimental ultrasonic action time is increased to 30 s. The two specimens obtained this time were sampled for metallographic observation and mechanical property test, as shown in Figure 2 and table 2 respectively.

It can be seen from Figure 2 that there are irregular graphite balls in figures (b) and (d) without ultrasonic treatment, as shown in area a; There are some parts of nodular graphite that are not nucleated, as shown in area B. There are no obvious irregular graphite balls in figures (a) and (c) after ultrasonic treatment. The ferrite content is calculated by software. The ferrite content of the specimens after ultrasonic treatment is 10.10%, and that of the specimens without ultrasonic treatment is 12.85%. Through mechanical test, it is found that the tensile strength, elongation and impact toughness of the specimens after ultrasonic treatment are slightly better than those without ultrasonic treatment.

| Test piece No | Ferrite content /% | Tensile strength / MPa | Elongation after fracture /% | Impact toughness / J | Hardness / HB |

| 1 | 10.10 | 820 | 3.7 | 25.0 | 269 |

| 2 | 12.85 | 815 | 2.7 | 23.7 | 270 |

The above two groups of experiments can show that applying ultrasonic treatment to the solidification process of nodular cast iron can increase the number of graphite balls, reduce the content of ferrite, improve the roundness of graphite balls, and slightly improve the mechanical properties.