From the simulation results of traditional gating system, the following two aspects should be paid attention to when designing the gating system of blade casting:

- When designing the gating system, try to avoid the phenomenon of “random pouring” and erosion in the pouring process, so as to avoid the defects of sand holes, pores and oxidized inclusions in the casting.

- Under the condition that the pouring speed remains unchanged, it is necessary to ensure that the molten steel can be filled and the gas in the mold cavity can be discharged quickly and smoothly.

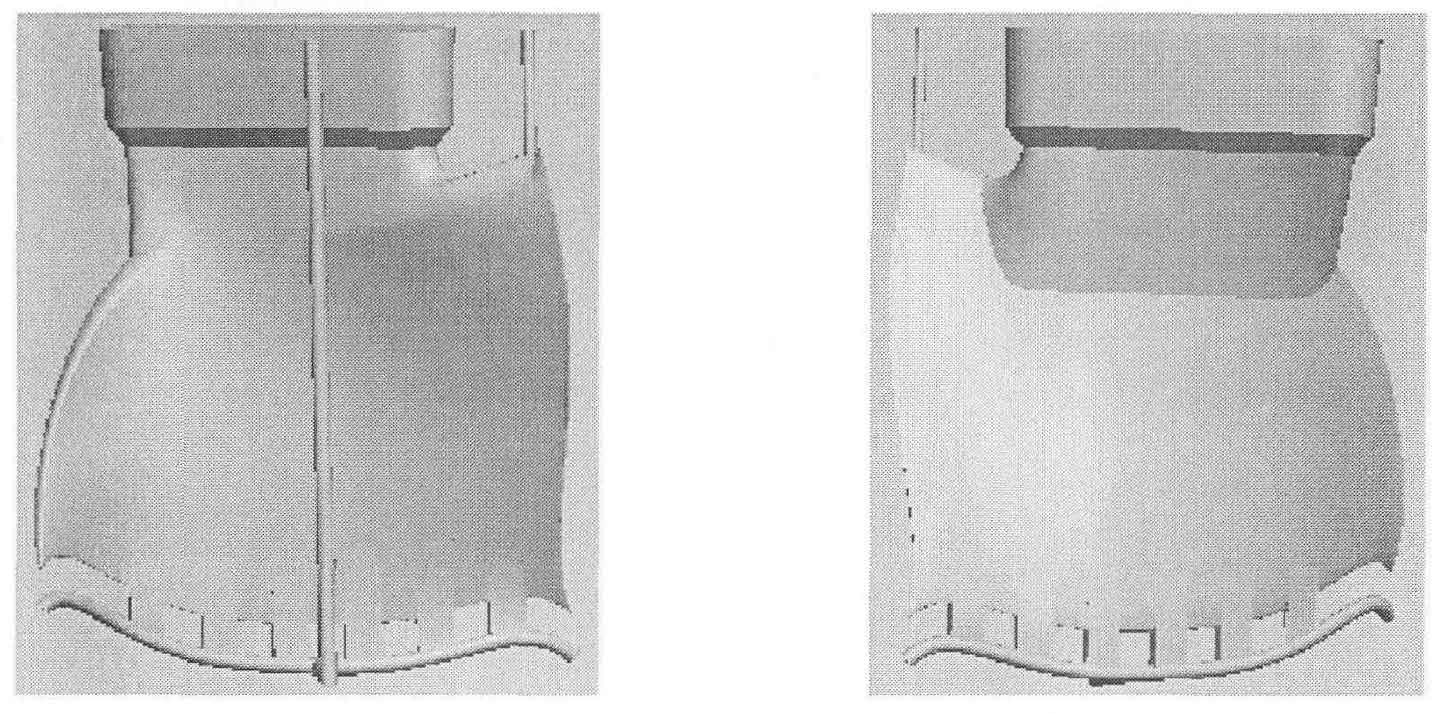

According to the above principles and fluid flow theory, the traditional gating system is improved. Instead of the stepped gating system, the bottom pouring gating system is adopted. The inner sprue of such gating system is placed at the bottom of the casting, so that the ratio of liquid metal entering the mold cavity is stable and the impact on the sand mold is small, which is conducive to the discharge of gas in the mold from the riser. At the same time, due to the discharge edge of blade casting and the upper crown The wall thickness difference at the lower ring is relatively large. Placing the gating system at the drain edge is more conducive to adjusting the temperature field distribution of blade casting.

In the mold filling process, the inner sprue of this gating system basically works under the submergence of liquid metal, which can avoid splashing and oxidation of liquid metal. The dimensions of each gate of the improved gating system are: Φ 140mmx1, 140mmx1 transverse gates and 720mm2x6 inner gates. The total area ratio of each gate is Σ a straight: ∑ a transverse: ∑ a inner = 1.0:1.0:4.8. The three-dimensional solid diagram is shown in the figure.