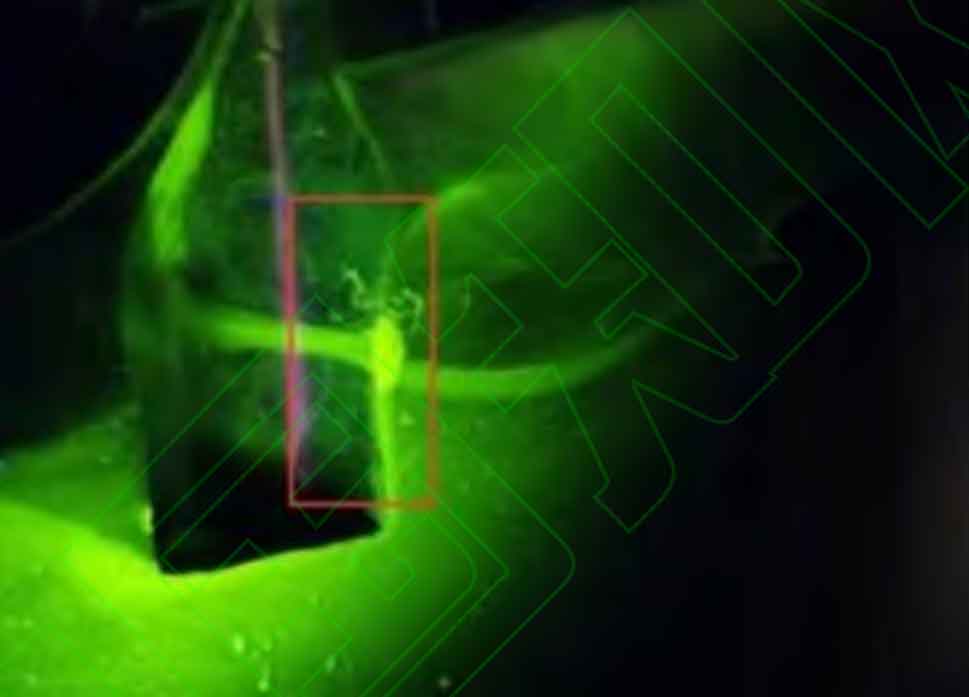

Through the testing of the original investment casting prototype, it is found that there are shallow cracks at the intersection of the hook head and the hook tongue through fluorescent magnetic particle testing, as shown in Fig. 1. Generally, the main reason for the formation of hot cracks in the process of investment casting is that the mold shell is thick and the compressive strength is high. However, the investment casting has large size, complex shape and uneven wall thickness, and its solidification shrinkage is blocked. The combined action of thermal stress and mechanical stress leads to cracks in the stress concentration part at the end of solidification.

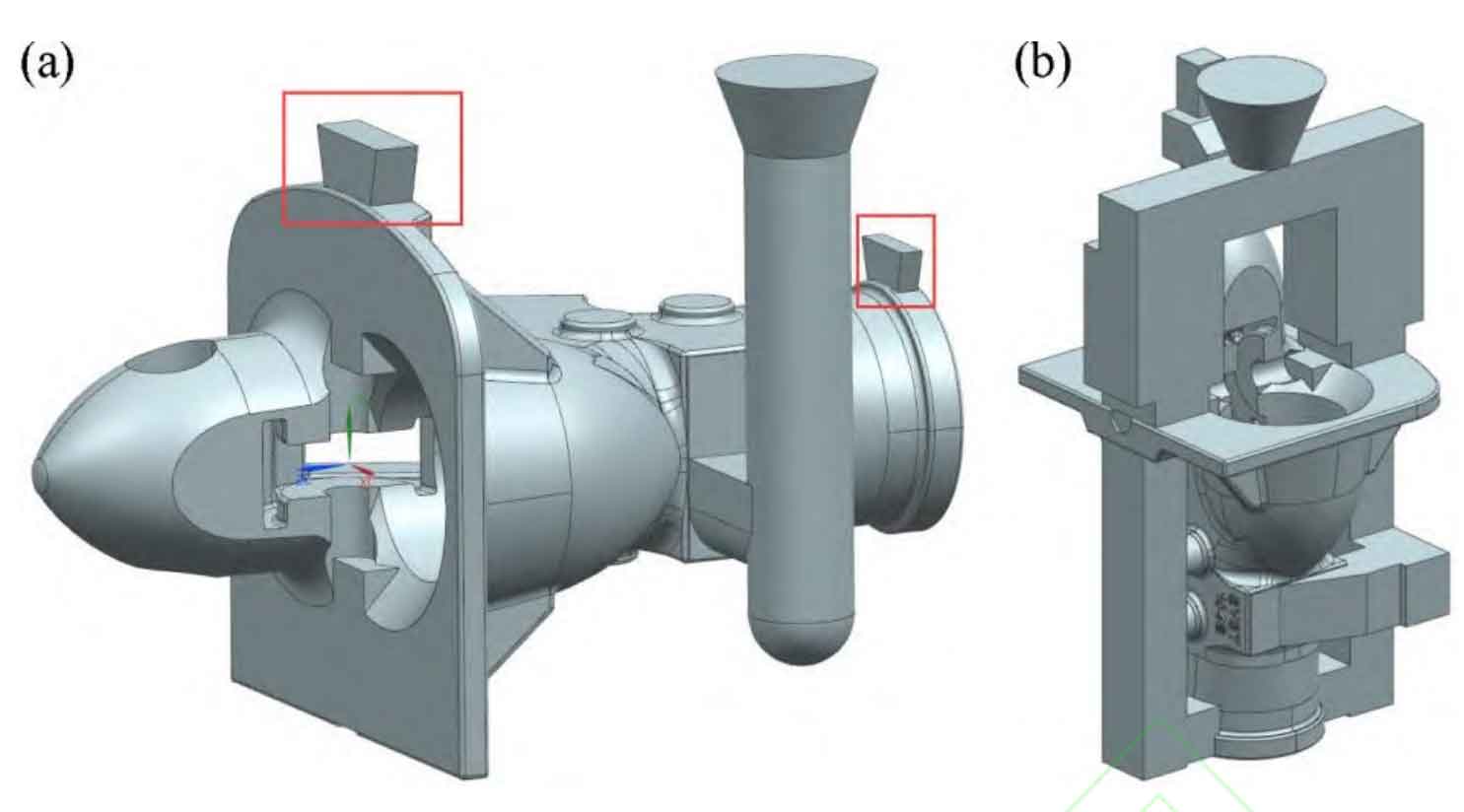

According to the above defect analysis and considering the investment casting process and production cost, two gating system schemes are designed as shown in Figure 2. Figure 2 (a) is scheme a and Figure 2 (b) is scheme B. Scheme a is designed based on the considerations of saving metal materials, simplifying the model and reducing the temperature loss of metal liquid. Theoretically, the scheme has the advantages of simple structure, convenient modeling, less metal consumption of metal riser and gating system, good filling capacity, convenient cutting of gating system after pouring, which can greatly reduce the use of materials and simplify the shell making process, In addition, an open riser (frame selected part) is set on the upper part of the flange of the investment casting to provide feeding during solidification. Scheme B is based on the feeding design for the thick and large parts of the investment casting. The scheme adopts vertical symmetrical pouring to increase the number of gates and the volume of the sprue. In particular, a large volume sprue is set at the joint between the coupler neck and the shoulder for feeding the joint, and an open riser is set at the top for exhaust feeding at the top of the coupler head, so as to realize sequential solidification as far as possible, so as to transfer the internal shrinkage defects of the investment casting to the gating system.