Place cold iron at the position where it is difficult to set the riser or where the riser is not easy to feed to reduce or prevent shrinkage cavity and porosity defects; Chilling with cold iron can increase the temperature gradient from the surface to the core of wind power hub casting, which is conducive to improve the utilization of graphitization expansion and the feeding effect of riser.

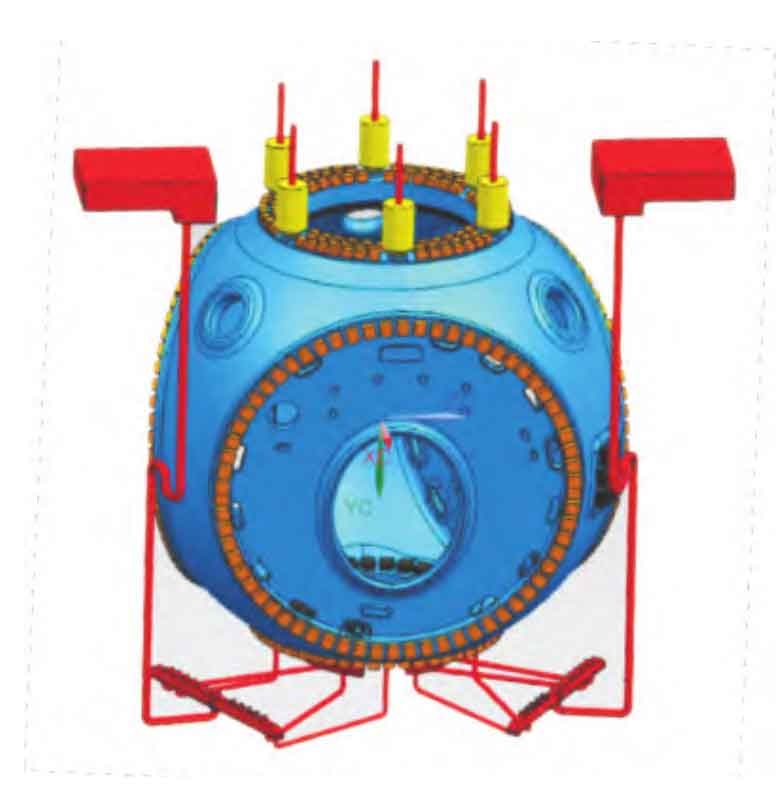

The wind power hub casting must be large. Generally, cold iron shall be set at the thick parts such as the top surface of the main shaft hole and the side of the pitch flange or at the cross hot joint, as shown in the figure, which is the cold iron arrangement of a certain type of wind power hub casting.