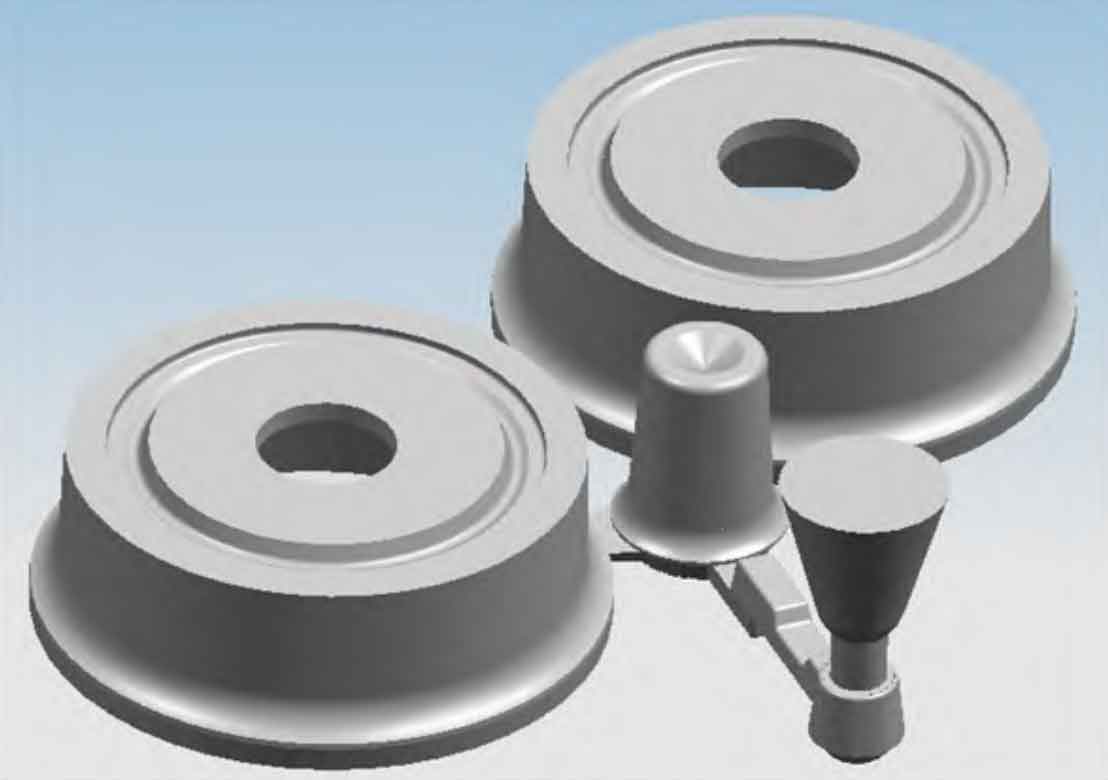

The casting material brand of brake drum is HT250, which adopts Yingda electric furnace to melt molten iron, fcmx Xindong horizontal molding line to shape, two pieces in one box, semi open gating system and sprue ratio of Σ F straight: Σ F horizontal: Σ F inner = 0.9:1.2:1, a riser is set in the middle of the model, and the filter screen is placed at the overlap of the runner. It is molded with green sand without core. The specific casting process of the brake drum is shown in the figure. The pouring temperature is 1360 ~ 1460 ℃, and the pouring speed is 3.2 kg / s.

The charge ratio is 2.5% pig iron + 15% scrap steel + 10% scrap steel + 32.5% return charge + 40% scrap iron. The chemical composition is: w (c) 3.22% ~ 3.38%, w (SI) 1.99% ~ 2.15%, w (MN) 0.65% ~ 0.85%, w (P) < 0.07%, w (s) 0.05% ~ 0.1%, w (CR) 0.1% ~ 0.3%, w (Cu) 0.1% ~ 0.2%. 0.43% bottom inoculation + 0.05% flow inoculation (the inoculant is 75sife with different particle sizes).