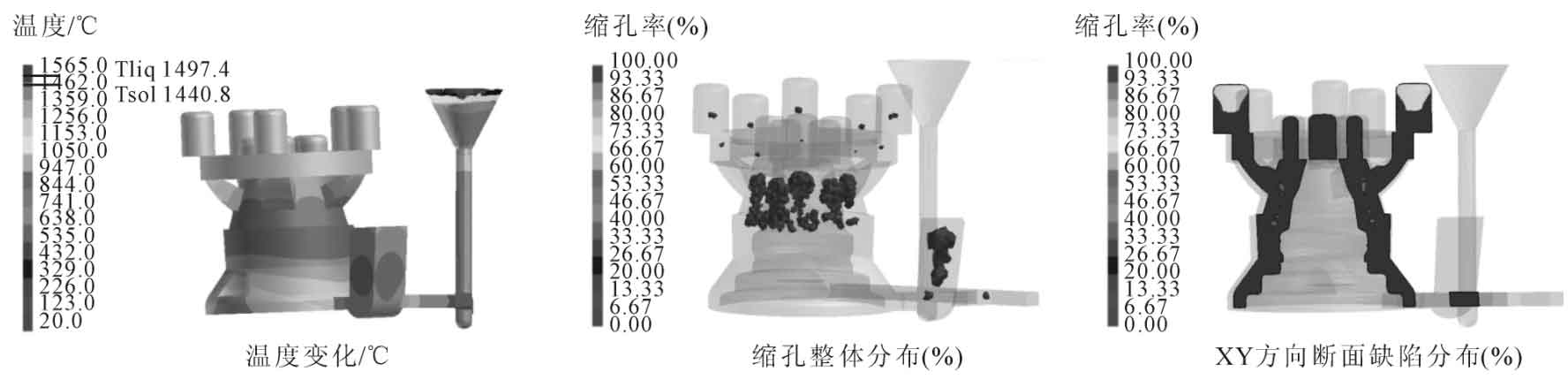

ProCAST software is used to simulate and calculate the scheme before process optimization of wheel hub steel casting. The judgment of shrinkage cavity and porosity of the simulation results is shown in the figure. It can be seen that the simulation results of the original process scheme are consistent with the shrinkage cavity parts of the actual casting.

According to the physical anatomy of the wheel hub steel casting and the results of ProCAST simulation, the main reason for shrinkage cavity and porosity is the unreasonable structure of the casting. The thickest part of the casting is from the oil leakage area to the upper tie bar root, and the channel above the tie bar root is narrow. In the process of solidification after pouring, the ordinary riser of sand mold does not play its due role in feeding and cannot form a feeding channel, The feeding capacity from the oil leakage area to the root of the upper tie bar is insufficient, resulting in shrinkage cavity and porosity defects.