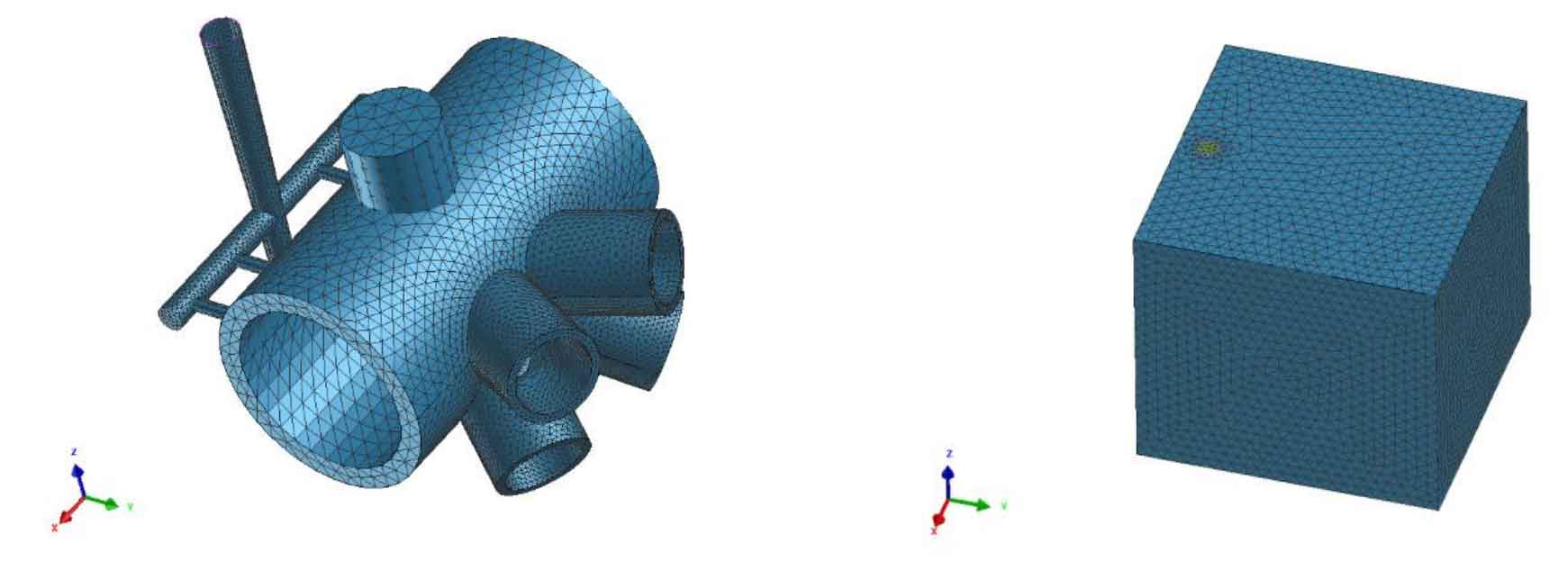

The three-dimensional steel casting model and sprue model established in AutoCAD are combined into a whole and saved as Import in sat format into visual mesh. Visual mesh is the mesh generator of ProCAST, which can automatically generate 2D mesh and 3D tetrahedral mesh. The visual mesh module can check the negative Jacobian elements and bad elements in the model and repair them, that is, smooth these elements. If they still fail after modification, it is necessary to consider manually modifying the mesh and solid model. Because the sand box and sand core are the same material, the sand core is not modeled separately. After assembling the steel casting and sand box, the surface mesh is divided. When meshing the surface, the mesh of steel castings can be densely divided and the mesh of sand box can be coarser, which can save computing resources and show the detailed characteristics of gating system. Mesh generation needs to form triangular mesh on the surface first, and then tetrahedral mesh can be generated. As shown in Figure 1, steel castings, sand boxes and their unit division effects are shown, with a total of 461166 units.

After checking and repairing the grid, you can directly enter the visual cast interface. Since it is not inclined casting, you can directly set the gravity direction, and then set the material type, initial temperature and initial filling degree. If the alloy composition of gs20mn5 steel casting in the material library is similar to that of gs20mn5 steel casting, relevant material parameters can also be set. The type of sand is quartz sand actually used in steel casting plant.

| Element (%) | C | Mn | Si | S | P | Ni |

| Requirement | 0.17~0.23 | 1.00~1.60 | ≤0.60 | ≤0.020 | ≤0.020 | ≤0.80 |

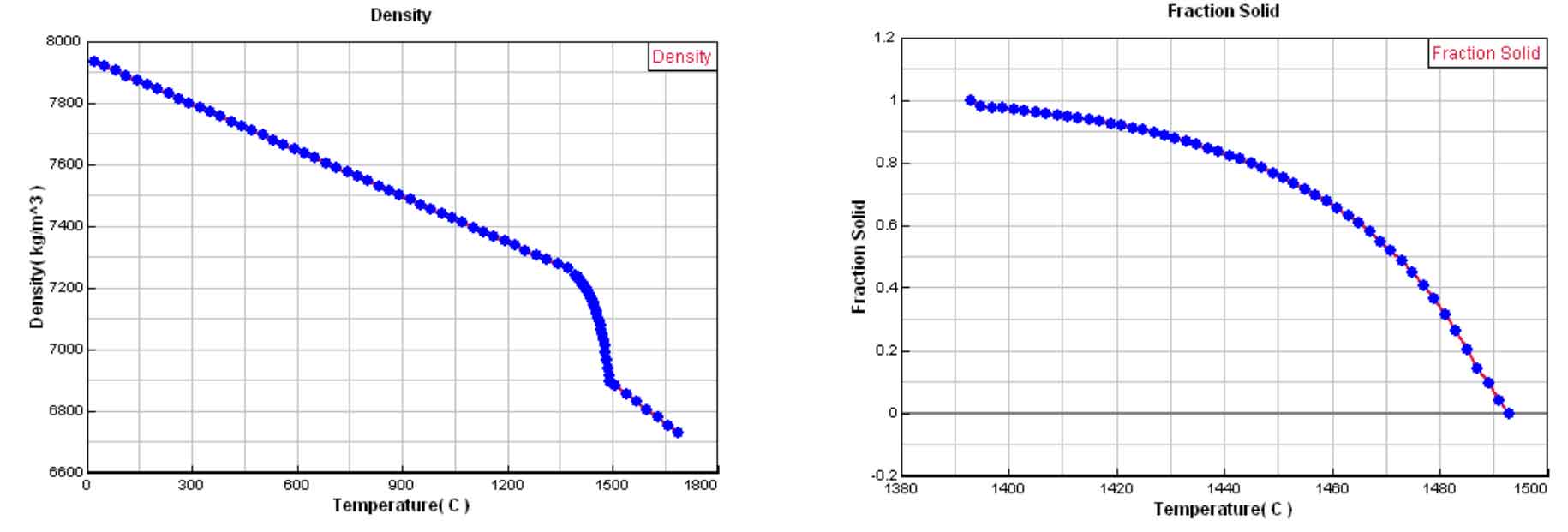

The thermophysical parameters of gs20mn5 steel castings in the material warehouse are shown in Figure 2.

Boundary conditions include the following items: temperature, heat, velocity, pressure, inner gate, turbulence, etc. The main boundary conditions used in this sand mold gravity casting are heat transfer and inner gate. The heat transfer boundary condition can define the heat exchange coefficient between the outer surface of a given domain and the external environment (such as air, water, etc.). The inner gate boundary condition can be used to set the inlet velocity and inlet temperature equivalent to the filling time, and the inlet flow velocity can be a function of time. Finally, the casting type is gravity casting. There is usually a temperature drop at the interface between two different materials (such as castings and molds). At this time, the nodes of the interface should be dual in order to distinguish the temperature at both ends of the interface. During grid generation, there is only one node on the interface, and the interface nodes must be doubled at this stage. Select coinc (consistency interface) to double the interface nodes.

(b) Relationship between Young’s modulus and temperature

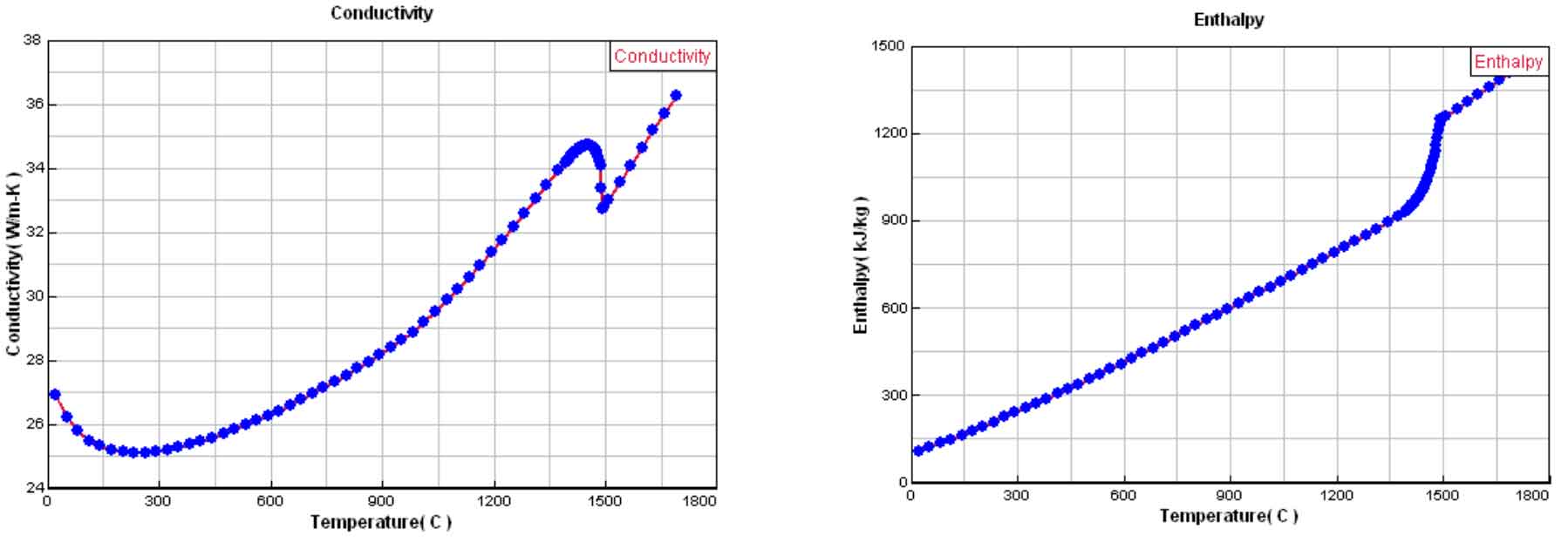

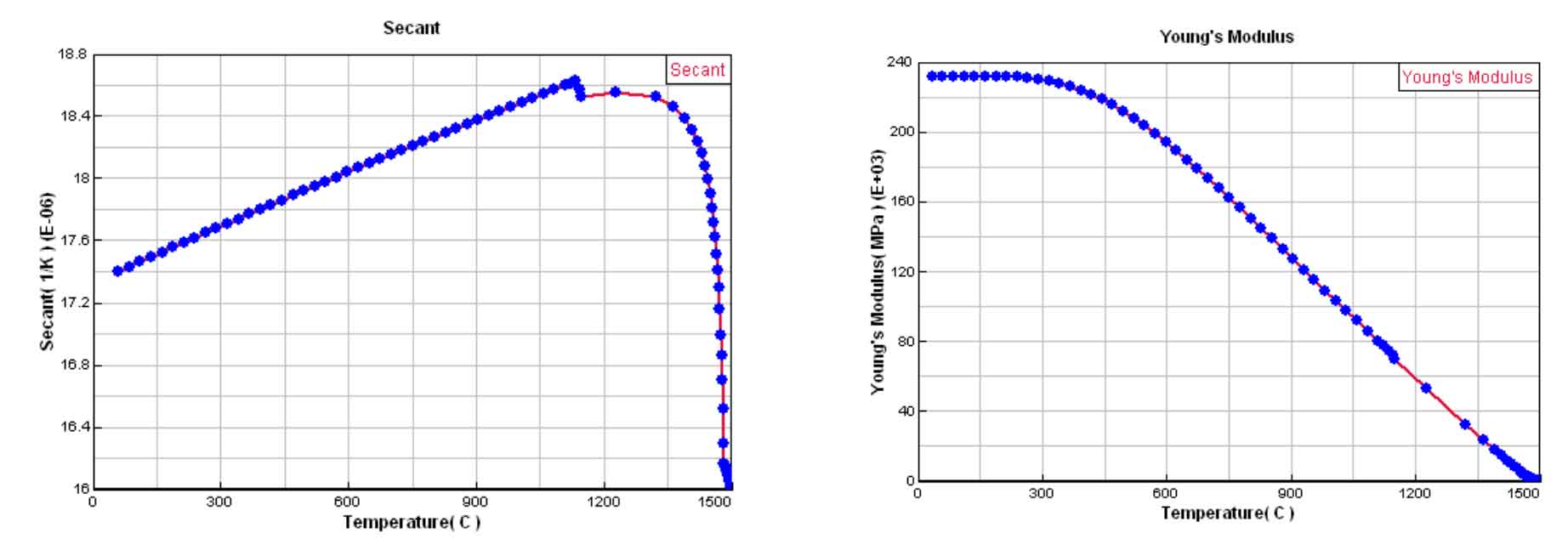

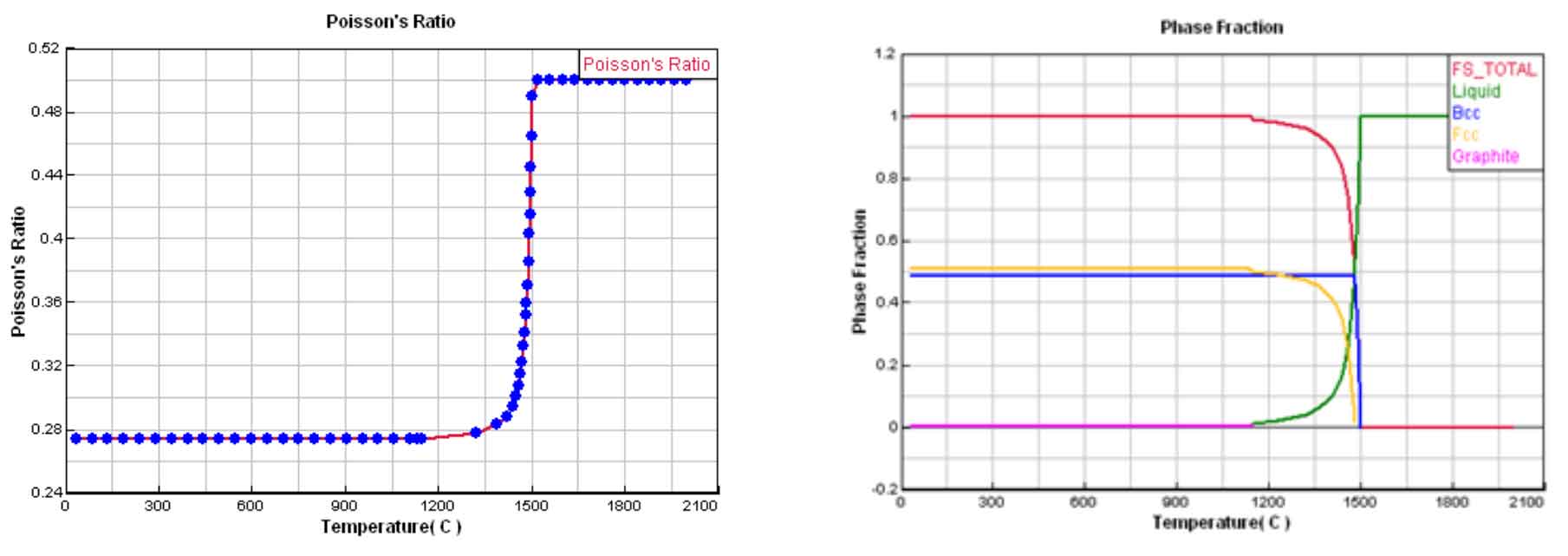

(d) Solid fraction curve and function of different phase with temperature

In addition to thermophysical parameters, some stress parameter values can also be calculated. The variation curves of Young’s modulus, Poisson’s ratio and thermal expansion coefficient with temperature can be calculated according to the phases calculated from the thermodynamic database. The classical Scheil Gulliver model of solid-phase non diffusion and liquid-phase uniformly mixed solute redistribution can be used to calculate the solid-phase rate curve of alloy materials and the functions of different phases with temperature. The calculation results are shown in Fig. 3. The calculation results show that the solidus temperature of steel castings is 1144.7 ℃ and the liquidus temperature is 1501.5 ℃. To sum up, the basic parameters of this casting simulation are shown in the table.

| Parameter type | Parameter setting |

| Casting and sand mold materials | Sand mold: silica sand Casting material: Gs20Mn5V |

| Interfacial heat transfer coefficient | Castings and sand molds are generally taken as (500 W / m2-k) Castings and sand molds are generally taken as (10W / m2-k) |

| Boundary condition | Gate temperature: 1560 ℃ Casting time: 16S Casting speed: 40kg / S initial condition |

| Initial condition | Cooling mode: air cooling Constraint condition: constrain the displacement of sand box in Z direction Casting temperature: 1560 ℃ Sand mold temperature: 25 ℃ Casting method: sand mold gravity casting |