During the trial production of coupler steel castings, the process scheme is continuously optimized and the casting quality is continuously improved. Finally, qualified coupler parts can be stably produced, which shows that the quality inspection results of coupler steel castings meet the requirements of relevant technical indexes. The quality inspection results of qualified parts obtained from trial production of hook body and hook tongue by improved and optimized process are introduced in detail.

(1) Physical and chemical properties

| C | Si | Mn | P | S | Ni | Cr | Mo | Cu | Al | As |

| 0.270 | 0.340 | 1.350 | 0.014 | 0.007 | 0.390 | 0.480 | 0.240 | 0.050 | 0.040 | 0.007 |

The physical and chemical performance test mainly includes the chemical composition, mechanical properties and metallographic structure of the coupler, and the test results all meet the specified requirements.

| Category | Tensile strength (MPa) | Yield strength (MPa) | Elongation after fracture (%) | Reduction of area (%) | -40 ° C impact absorption energy (J) | Tensile specimen (mm) |

| Type 17 Leptospira | 945 | 855 | 16 | 37 | 50 | 122×50 |

| Type 16 hook tongue | 940 | 860 | 16 | 35 | 31 | 122×50 |

| category | Type I, III | Type II | Other | Matrix structure |

| Type 17 Leptospira | None | None | None | Quenching and tempering organization level 4 |

| Type 16 hook tongue | None | None | None | Quenching and tempering organization level 4 |

(2) Compactness

| Profile | A-A | B-B | C-C | D-D | E-E | F-F | G-G | Tail A-A | Tail B-B | Tail C-C | Tail D-D |

| Specified level | ≤3 | ≤5 | ≤4 | ≤4 | ≤4 | ≤2 | ≤4 | ≤3 | ≤4 | ≤4 | ≤3 |

| Actual level | ≤1 | ≤1 | ≤1 | ≤1 | =1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

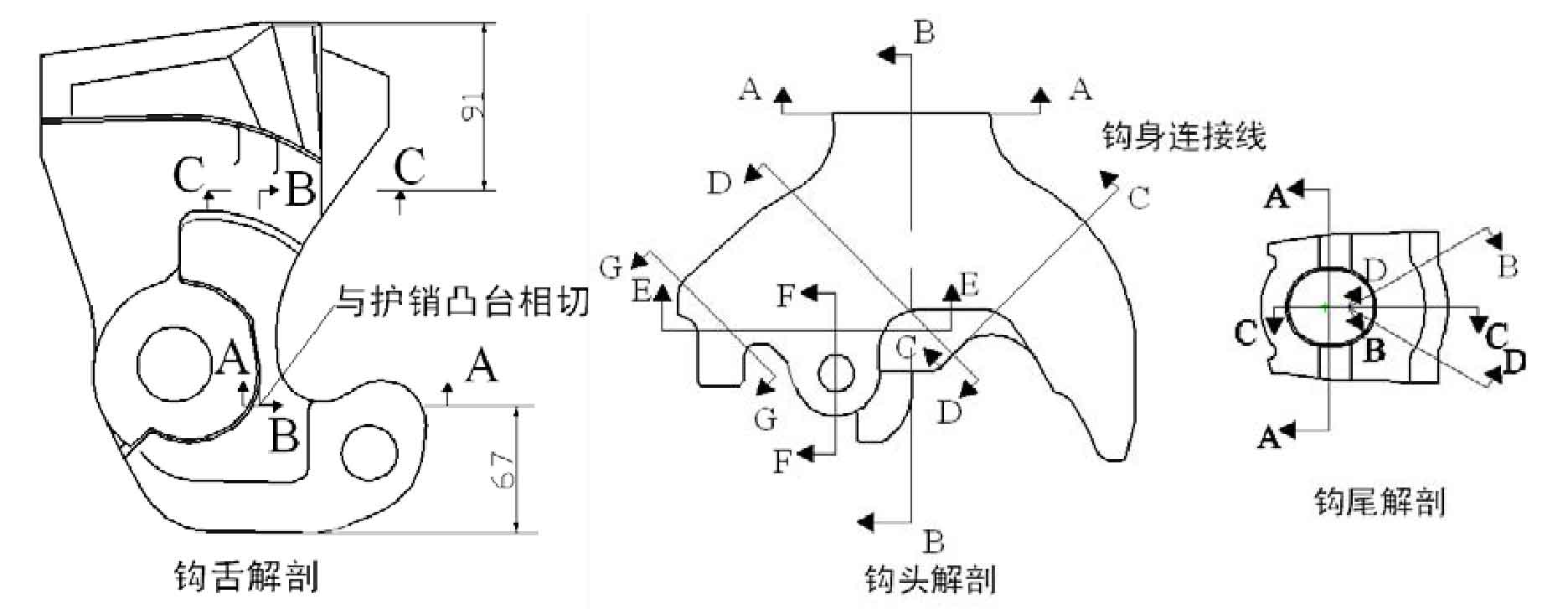

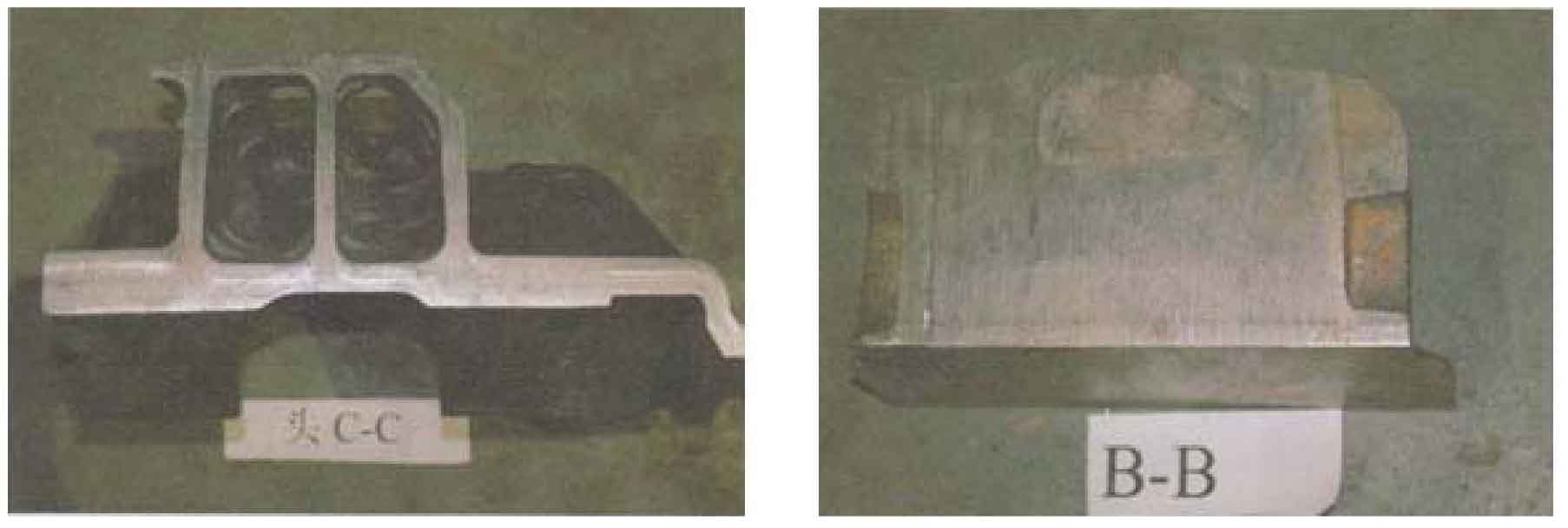

According to the technical standards, the coupler body and coupler tongue shall be dissected at the designated part, and the section compactness of the dissected section shall be tested. The cutting position of the coupler body and coupler tongue is shown in Figure 1. The test report of the compactness of the coupler body and coupler tongue is shown in table 4 and table 5. All the test results meet the specified requirements. The actual cutting photos of the steel castings of the coupler body and coupler tongue are shown in Figure 2.

| Profile | A-A | B-B | C-C |

| Specified level | ≤3 | ≤4 | ≤2 |

| Actual level | ≤1 | ≤1 | ≤1 |

(3) Surface quality and appearance dimension

The trial produced 16 and 17 type couplers (coupler body and coupler tongue) have been checked by CMM, sample plate and anatomy. The geometric dimension and wall thickness of each part meet the requirements of steel casting drawing. Through visual inspection, the steel castings are free of cracks and shovel marks on the inner and outer surfaces, and there are no steps, cracks and core supports at important parts of the inner cavity.

(4) Hardness

The surface of the hook tongue and the end face of the hook tail shall be subject to heat treatment, and the surface of the hook tail ball shall meet the requirements of type A. The hardness test report of coupler slice is shown in table 6.

| Category | Depth from traction surface 5mm / HBW | Depth from traction surface 10mm / HBW | Distance from end spherical surface 4.5mm / HBW |

| Type 17 Leptospira | 429 | 306 | 455 |

| Type 16 hook tongue | 448 | 302 | 406 |

(5) FeO content of slag sample in reduction period

The FeO content test results of slag samples in reduction period are shown in table 7.

| Sample name | Test items | Standard content /% | Test content /% |

| Slag | FeO | ≤1 | 0.85 |

(6) Dynamic tear

The dynamic tear test results meet the requirements, and the test results are shown in table 8.

| Sample name | Texture of material | Test temperature / ° C | DT/J |

| Noumenon | Grade E steel | -56 | 130 |

| Test bar | Grade E steel | -56 | 165 |

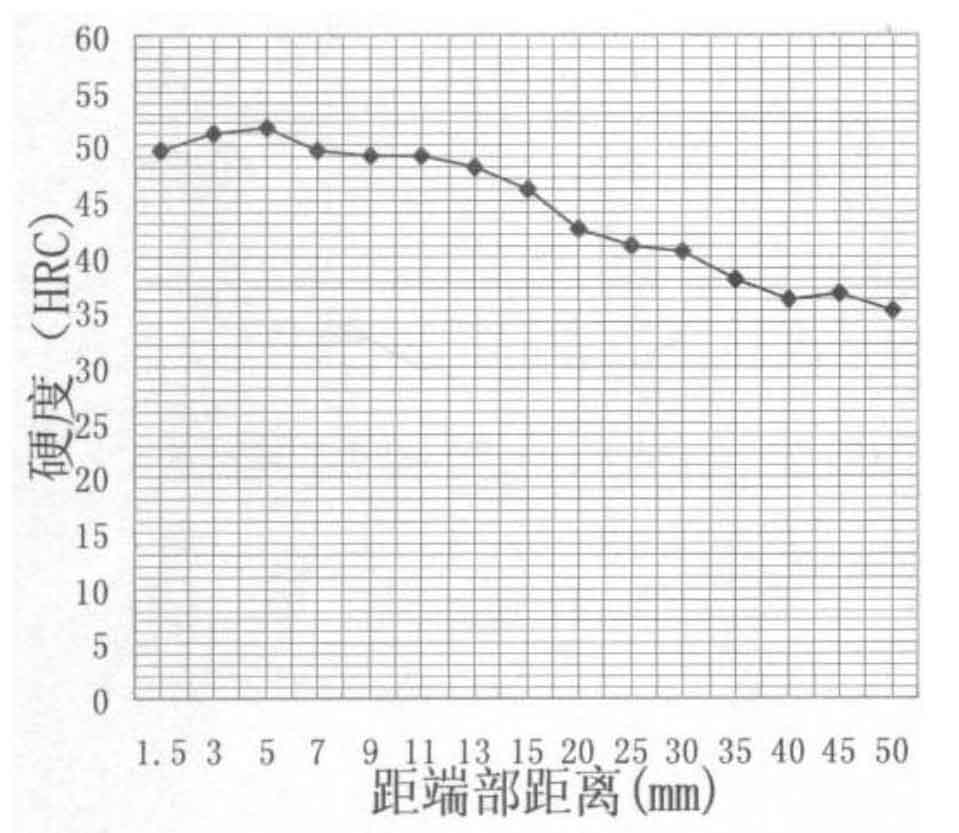

(7) Hardenability of Grade E steel

The test samples of 5 heats were selected for the hardenability test of Grade E steel. The test results meet the requirements, and the hardenability curve is shown in Figure 3.

(8) Static load tensile test

Two type 17 hooks and two type 16 tongues were randomly selected for static load tensile test. The test results meet the requirements. The test results are shown in table 9.

| Category | Technical requirements for maximum permanent deformation / mm | Maximum permanent deformation inspection result / mm | Technical requirements for minimum failure load / kN | Minimum failure load test result / kN |

| Type 17 Leptospira | ≤ 0.8 when loading 3115kn | 0.1 | ≥4005 | 4005 not broken |

| Type 16 hook tongue | ≤ 0.8 when loading 1780kN | 0.2 | ≥3430 | 3430 not broken |