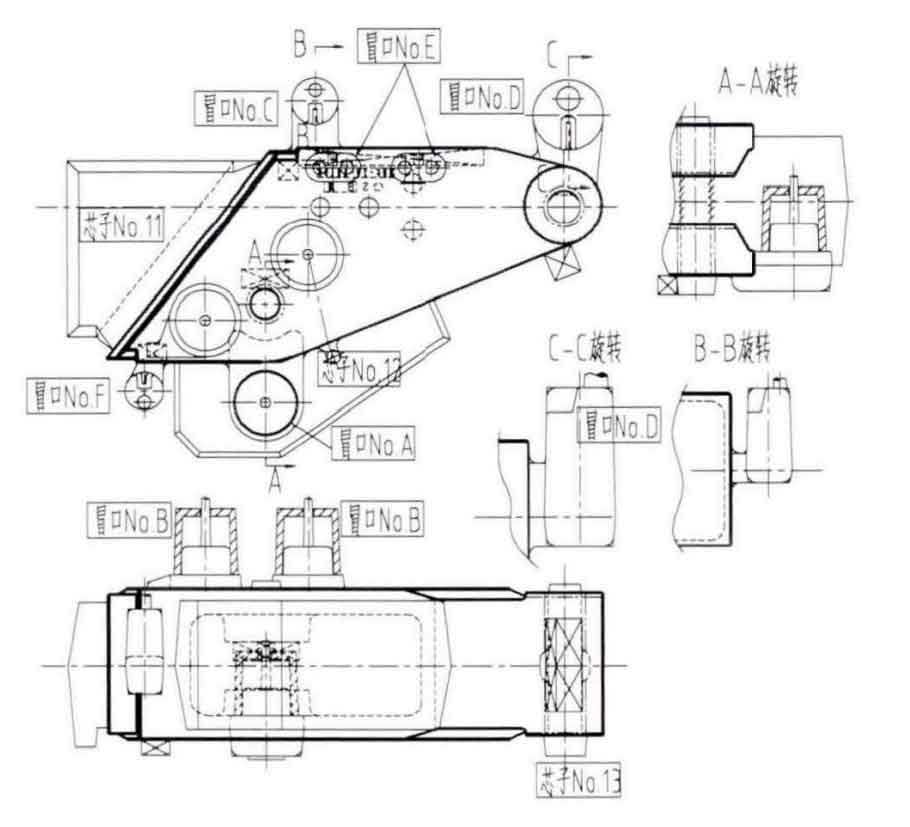

According to the above casting defect analysis and countermeasures, a new process diagram is finally formed, as shown in Figure 1.

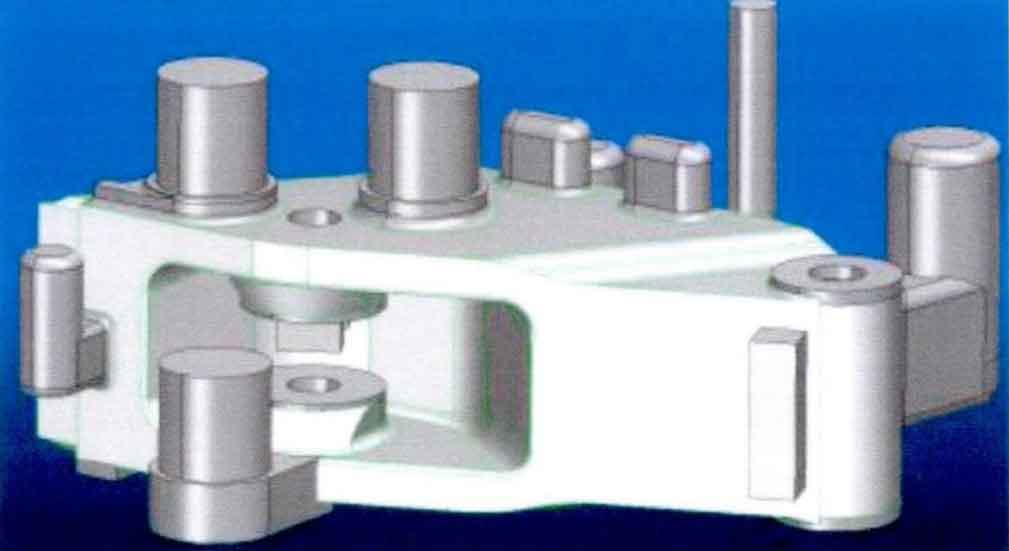

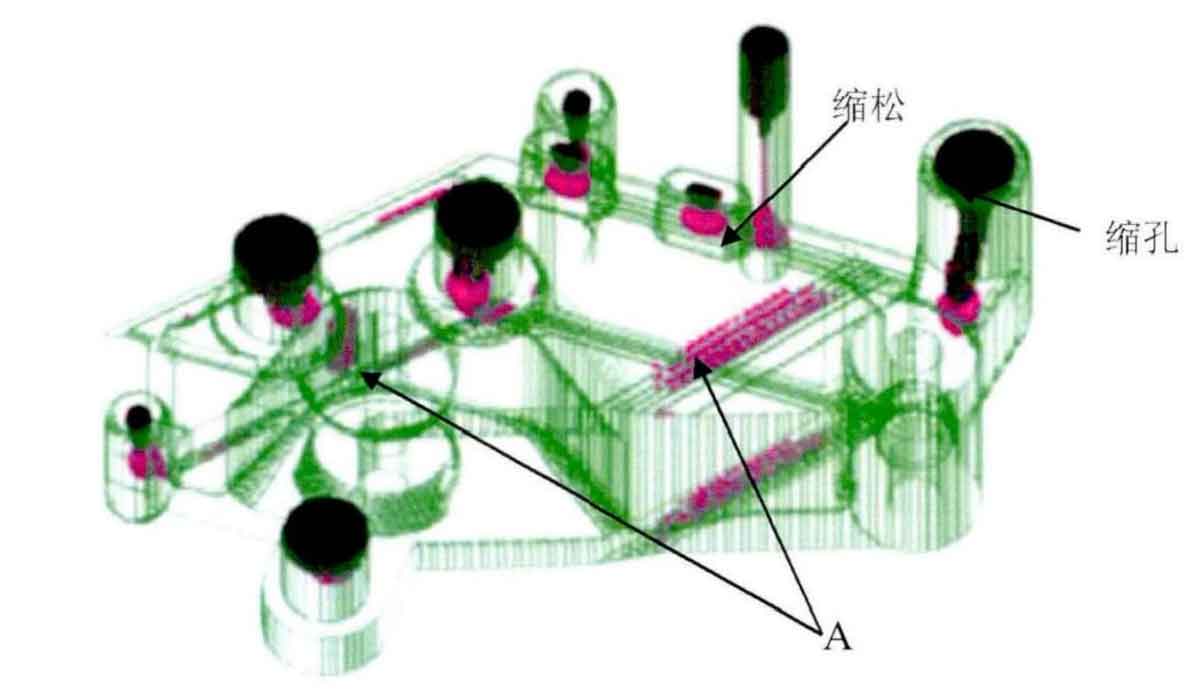

In order to verify the rationality of the new process of steel castings, after drawing the three-dimensional diagram, the solidification simulation was carried out by Huazhu CAE. Figure 2 shows the three-dimensional drawing. Fig. 3 is the effect diagram obtained by solidification simulation using Huazhu CAE. It can be seen from the effect drawing that shrinkage cavity and porosity are controlled in the pouring and riser system. The analog display at mark a in the figure is shrinkage. According to the past experience, when simulating the thin-walled part of steel castings, the shrinkage defects shown in the thin-walled part do not actually exist. The trial product k141 is subject to radiographic inspection, and the flaw detection results show that there are no casting defects in this part. Moreover, the change of the new tooling of steel castings has no direct relationship with this position. Therefore, through solidification simulation, it can be determined that the new process can eliminate the original shrinkage defects.

After trial production, ultrasonic flaw detection, radiographic flaw detection and processing confirmation were carried out for the test products of steel castings. It was determined that the shrinkage cavity and porosity defects had been completely eliminated by adjusting the process. Qualified steel castings and machined parts are shown in Figure 4.