The micro analysis of the worn surface of tractor track shoe is of great significance to study its wear characteristics and failure mechanism, reasonably select materials and treatment technology, and improve the service life of tractor track shoe.

1.Research methods

Through investigation, the severely worn tractor track shoes were removed from the tractor under cultivation for loading test. First clean the surface, attach it to the worn surface to be observed with acetate paper, then seal and package it with cellophane and plastic cloth, carefully protect it and transport it to the test room. In the laboratory, a wire cutter or a grinding wheel slicer can be used to cut small samples (about 10x10x10mm) from the parts to be observed. In order to prevent false images caused by corrosion and other factors during storage, the returned samples shall be cleaned for many times, stored carefully and observed in time. The micro analysis instrument mainly adopts optical microscope and scanning electron microscope. If necessary, transmission, diffraction and energy spectrometer are added for special observation. In order to observe the change of microstructure under the wear subsurface and the propagation of cracks, the method of oblique section after nickel plating should be used to look at the microstructure while looking at the wear marks.

2.Analysis of research results

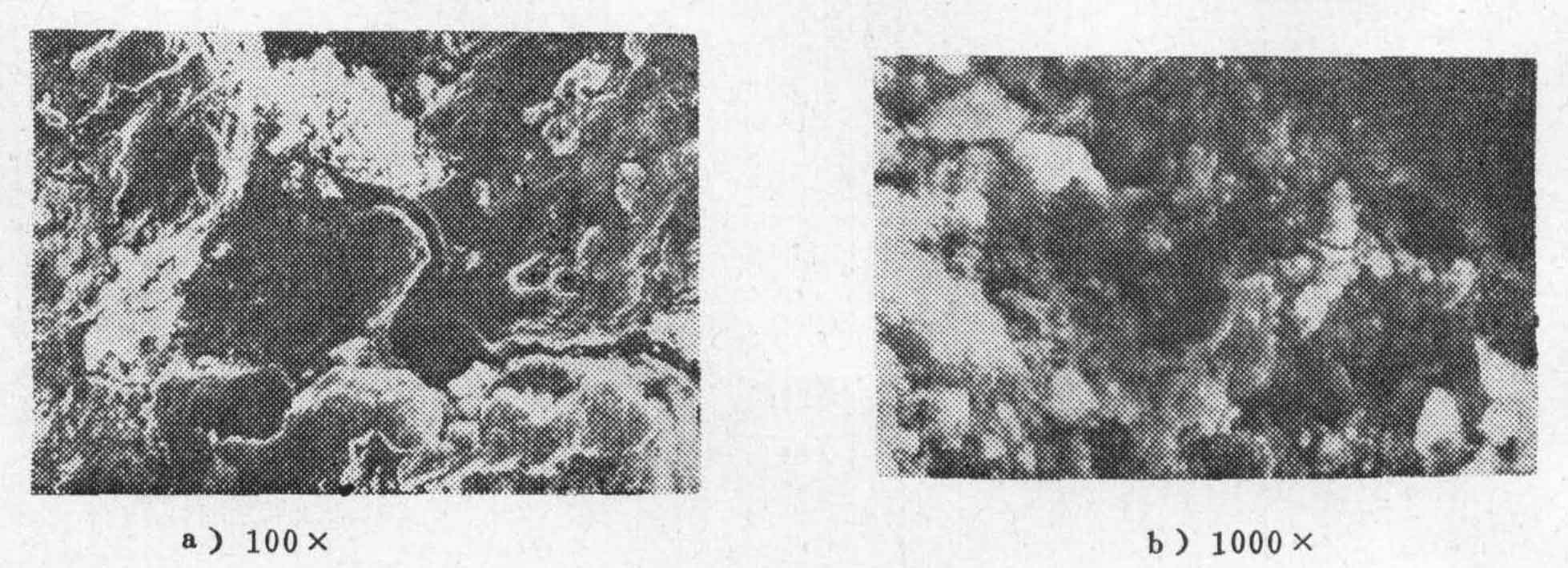

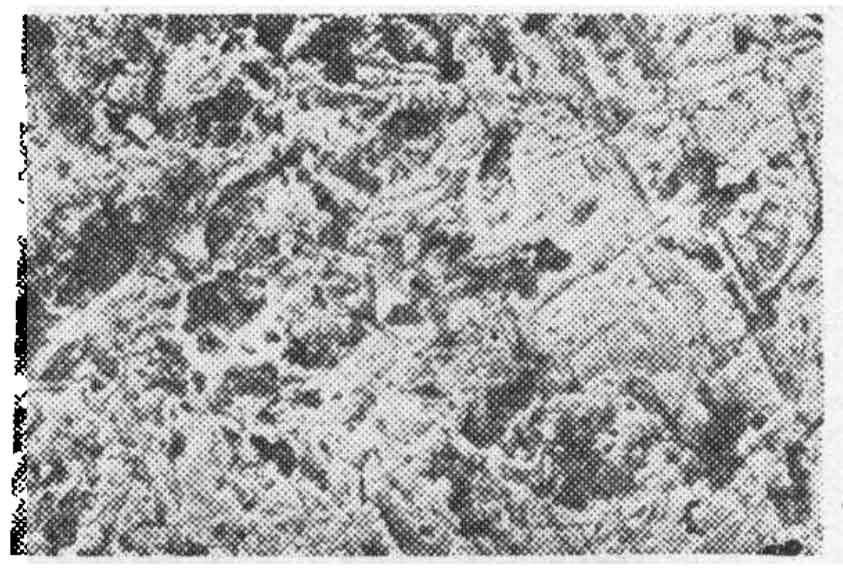

Fig. 1 is a SEM photograph of the joint pin of the tractor track shoe used in sandy soil area. The typical morphology of pit spalling and crack propagation can be seen from the figure. Observe the pit bottom with higher magnification. For materials with good toughness (such as Mn13), the morphology is similar to the ductile fracture of tear (Fig. 1b). In paddy field areas, microcracks often exist at the bottom of such pits (Fig. 2).

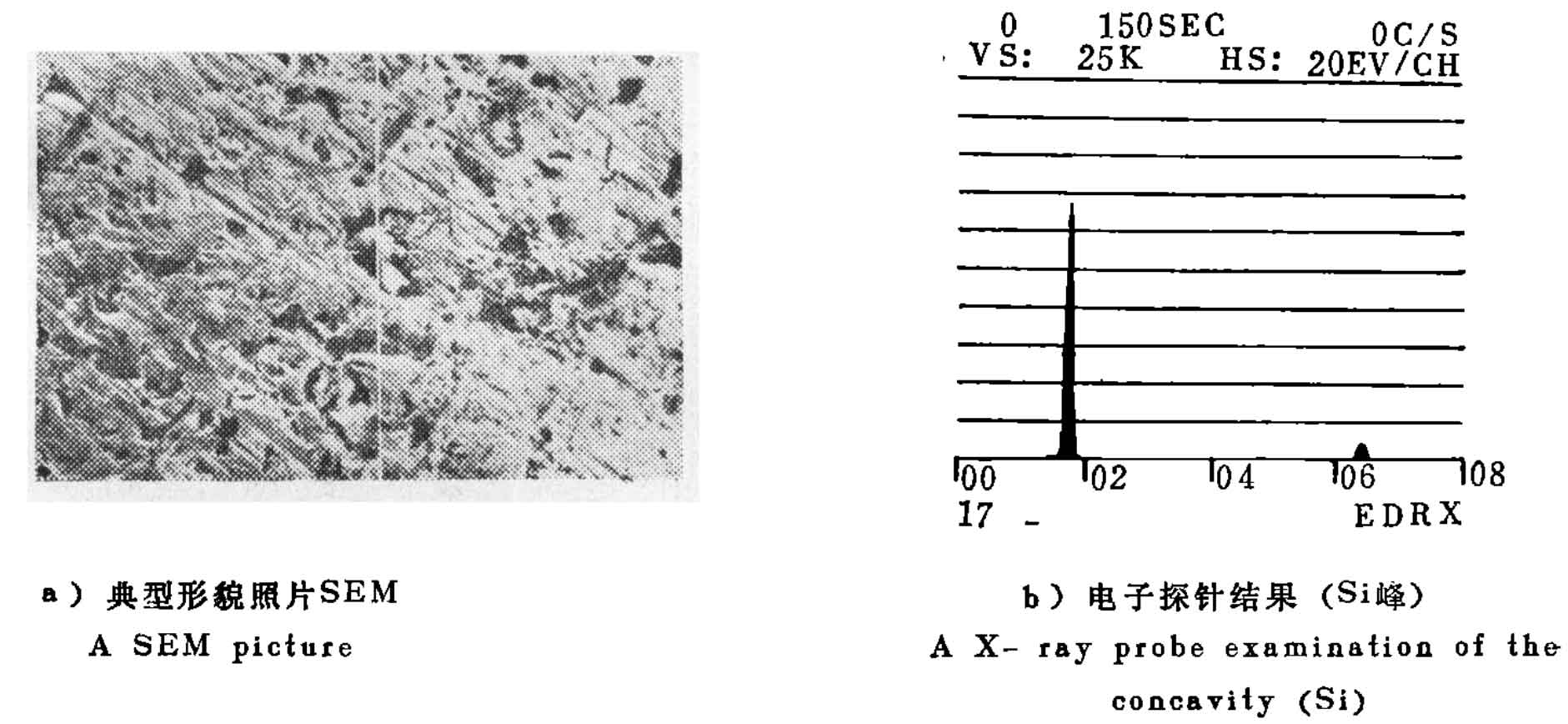

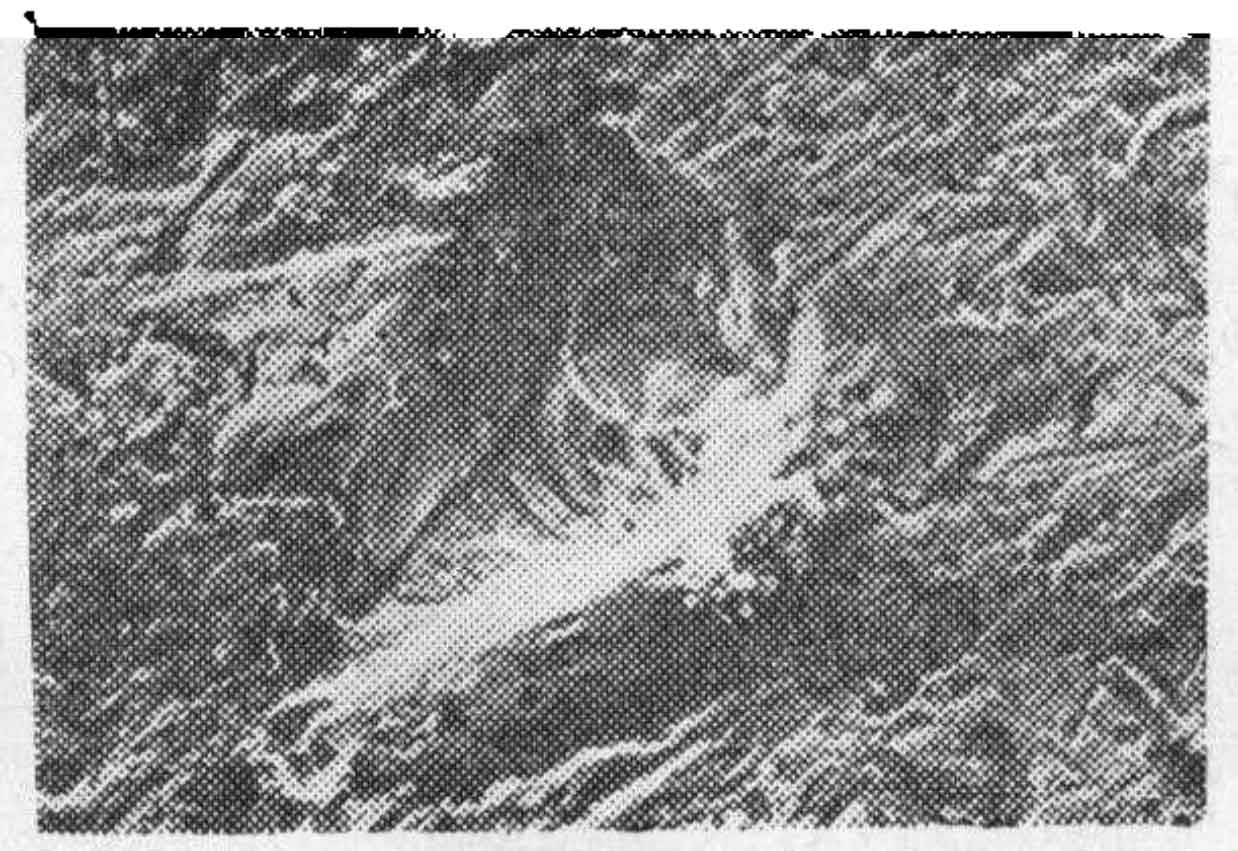

Fig. 3 and Fig. 4 are SEM photos (paddy field) of the track shoe pin hole and runway of Mn13 tractor. Its typical morphology is a small number of small furrows and pits, and corrosion pits can be found at the same time. The white substance in some pits is determined by probe, and its composition is Si peak. Therefore, it can be roughly considered that this pit is the result of the action of sand particles in the soil. In individual cases, serious defects of local chiseling and scratching caused by sand particles can also be seen (Fig. 5 and Fig. 6).

Under the condition of paddy field environmental medium, the “turtle crack” and pitting pit caused by corrosion can be clearly observed by using the secondary coating method to observe the wear surface under high-power transmission electron microscope. This kind of corrosion pit often gathers together to form obvious microcracks, which accelerates the peeling and failure of materials.