Thermoelastic and plastic models are used to calculate the thermal stress in the forming process of bimetal casting liner. The numerical accuracy of the affinity between temperature field and stress-strain field in the process is improved by analyzing the relevant theories of thermoelastic and plastic models.

The theory of thermoelasticity and plasticity is based on the theory of elasticity and plasticity. The influence of temperature field on material physical parameters and material deformation is comprehensively considered. The strain objects analyzed include elastic strain, plastic strain and thermal strain. The theoretical model is often applied to the numerical simulation of the affinity between temperature and stress-strain in the process of material hot working. It has strict reasoning logic and high accuracy of simulation results.

The solidification and cooling process of bimetallic liner casting process spans a large temperature range. From high temperature 1500 ° C to low temperature 500 ° C, the thermophysical parameters of two metal materials (high chromium cast iron and carbon steel) will also change greatly. The main parameters related to thermal stress numerical simulation include: elastic modulus, Poisson’s ratio, stress-strain relationship curve, thermal expansion coefficient, density Thermal conductivity, etc.

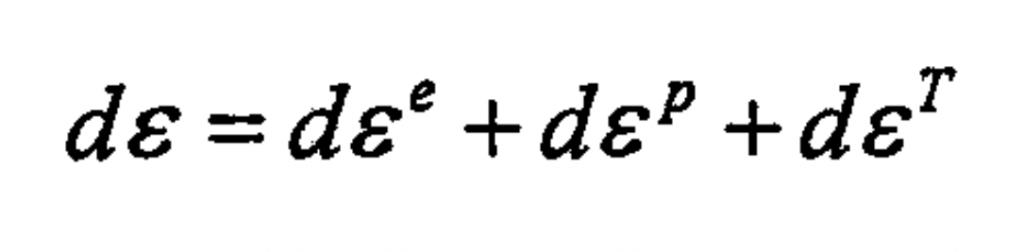

The law of thermal expansion and cold contraction makes the total strain increment consist of elasticity, plasticity and thermal strain increment, as follows: