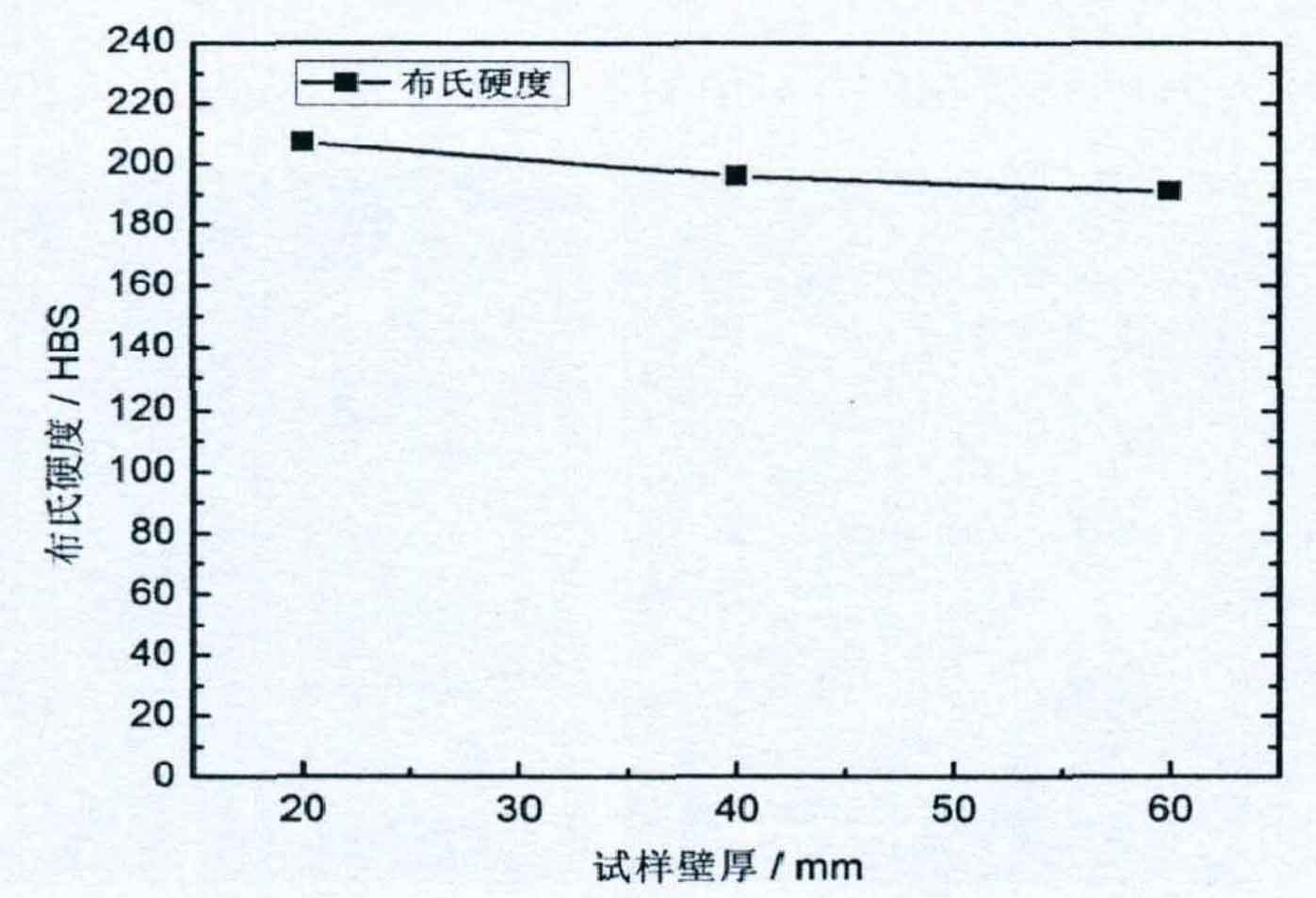

The figure shows the relationship between Brinell hardness of gray cast iron and sample wall thickness. It can be seen from the figure that the hardness value of gray cast iron gradually decreases with the increase of sample wall thickness.

In the gray cast iron with a wall thickness of 20mm, due to the fast cooling rate of the sample, the solidification undercooling of the gray cast iron is increased, the pearlite flake spacing is small, and the properties of the pearlite structure are brought into full play, so the hardness value of the gray cast iron is higher.

However, for the cast iron with wall thickness of 40mm and 60mm, due to its slow cooling speed, more solidification latent heat is released during eutectic reaction, which prolongs the eutectic solidification time of gray cast iron, and the precipitation of flake graphite is more sufficient. At the same time, the diffusion time of carbon atoms is prolonged during eutectoid transformation, the diffusion distance is increased, pearlite with large flake spacing is generated, and the hardness of gray cast iron is reduced. Moreover, the larger the wall thickness of the sample, the slower the cooling rate of the cast iron, the larger the pearlite flake spacing, and the lower the hardness value.