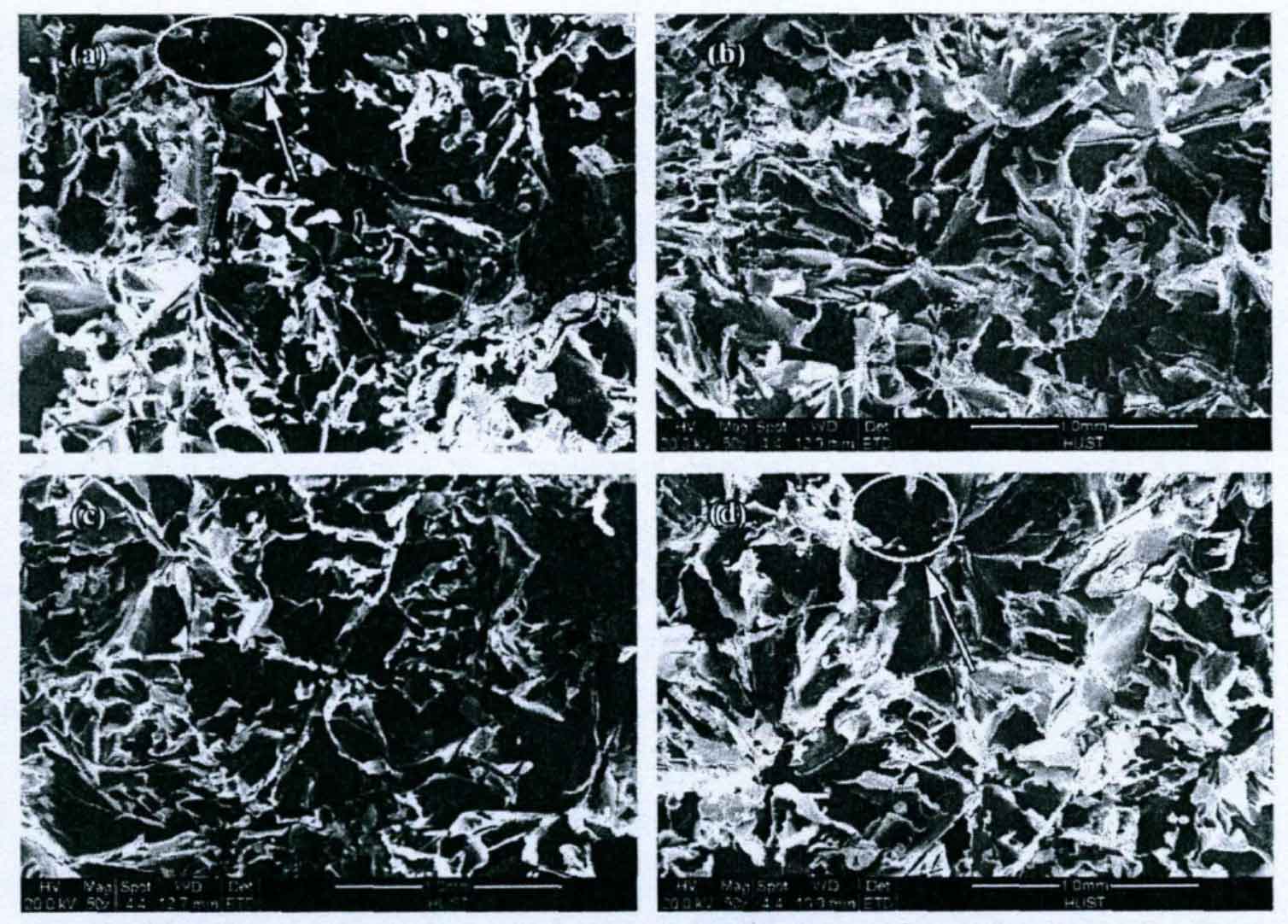

The figure shows the fracture morphology of gray cast iron with different vibration frequencies. Among them, figures (a) – (d) show the fracture morphology of gray cast iron prepared under the vibration frequency of 0, 35, 50 and 100Hz respectively.

It can be seen from the figure that the fracture surface of grey cast iron shows the cleavage fracture characteristics of A-type flake graphite and matrix structure, and there are many holes on the fracture surface. Heyi et al. Believe that these holes seem to be micro porosity formed during solidification of gray cast iron, and the researchers believe that the fracture of gray cast iron is caused by graphite cleavage or interfacial separation between graphite and matrix.

In addition, it can be seen from the figure that there are more flower shaped graphite on the fracture surface of gray cast iron. Heyi et al. Believe that in a eutectic cluster, the three-dimensional morphology of flake graphite is flower shaped, and the transformation products of eutectic austenite (pearlite or pearlite + ferrite) are distributed between the flowers. Because the strength of graphite is almost zero, when the alloy is under tension, the position of graphite is equivalent to the crack source, and cracking occurs before the matrix. After the graphite cracks, the cracks propagate to the matrix structure until the graphite at the front of the crack continues to crack, which eventually leads to the fracture of gray cast iron. When the crack propagates in the matrix, the matrix will hinder its propagation, so that the gray cast iron has only a certain tensile strength. However, in the gray cast iron, the flake graphite is distributed in the matrix of the gray cast iron, increasing the splitting effect on the matrix, so the tensile strength of the gray cast iron is low.

By comparing the size of holes in the fracture morphology of gray cast iron made with different vibration frequencies, it can be found that the size of hole defects in gray cast iron made without vibration and with vibration frequency of 100Hz is larger, as shown by the arrows in figures (a) and (d). It can be concluded that the tensile strength of gray cast iron made by these two processes is low. However, there is little difference between figure (b) and figure (c), which makes the properties of gray cast iron similar.