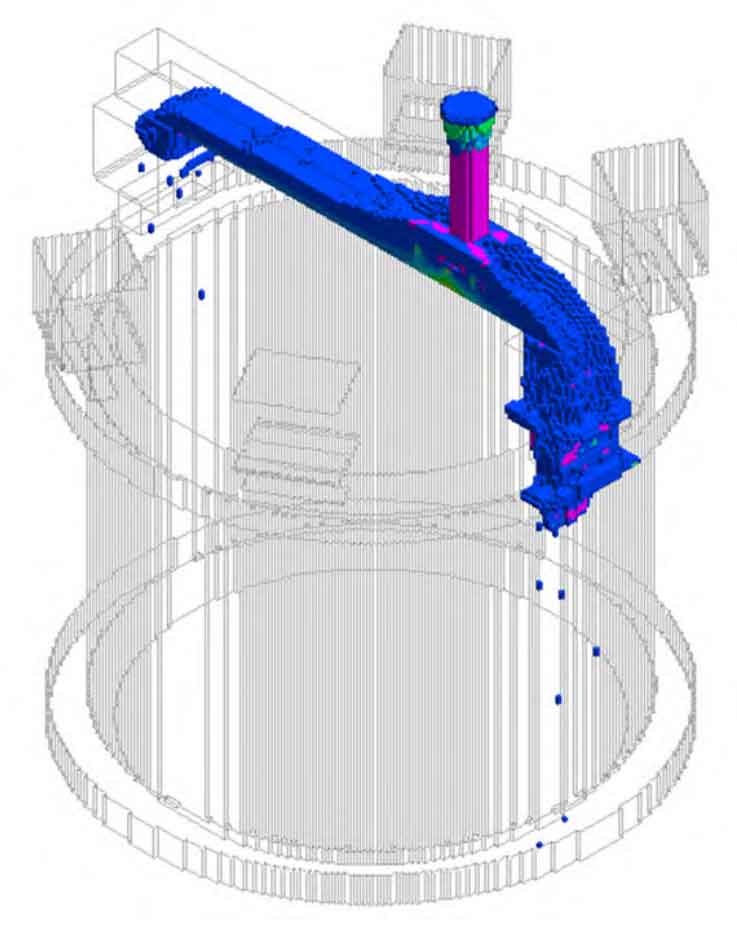

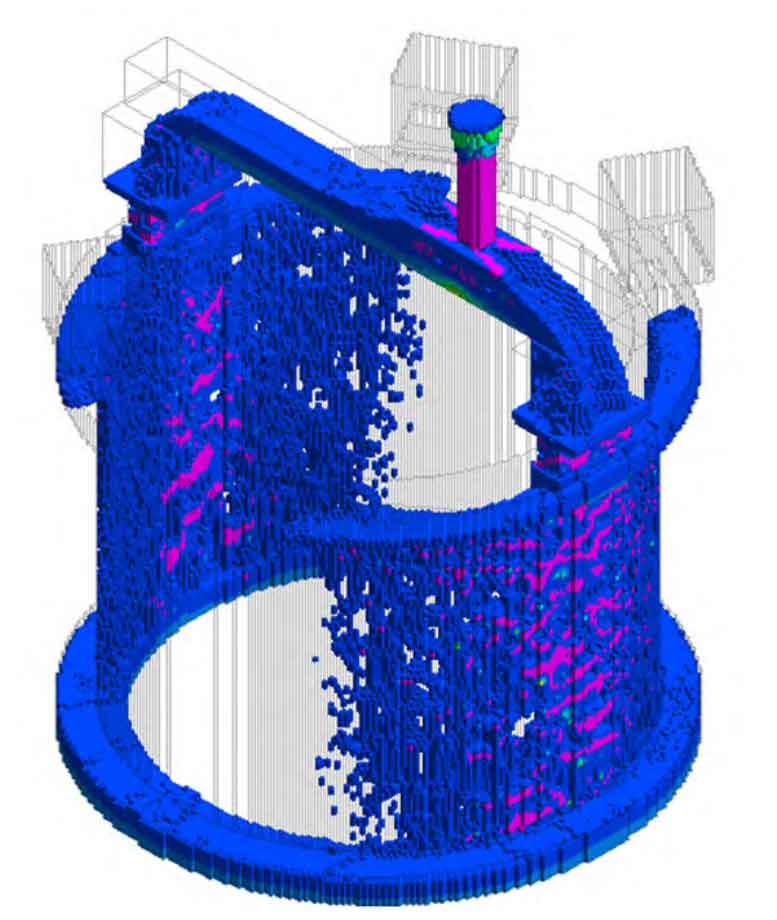

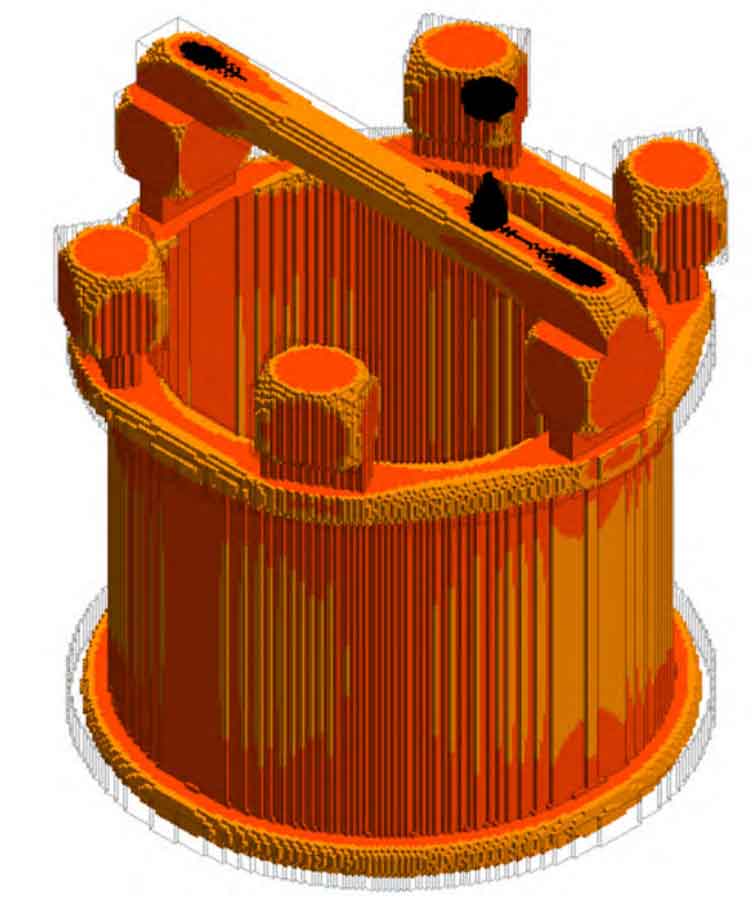

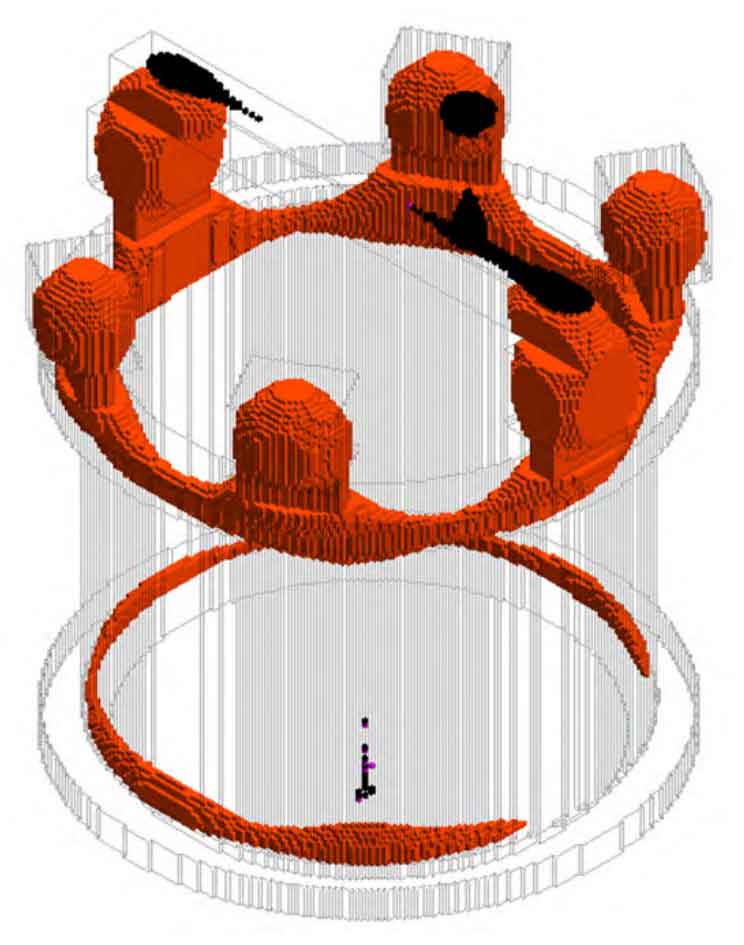

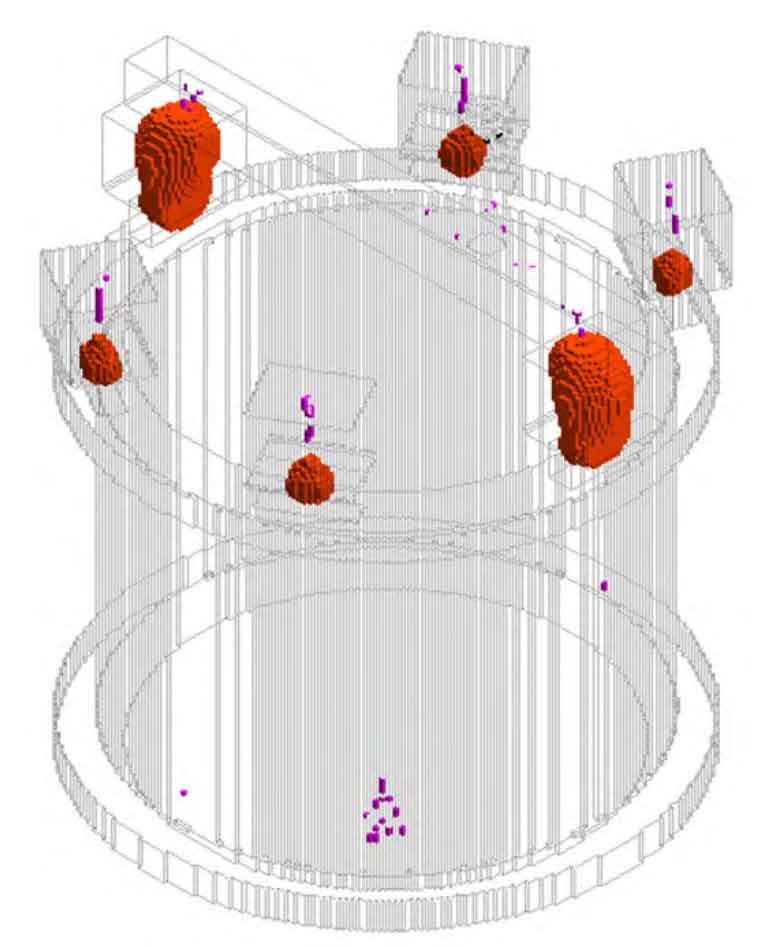

In order to verify whether the top pouring process is reasonable, whether the molten iron mold filling can ensure the smooth pouring, and ensure that the pouring system can effectively feed the shrinkage position of the vacuum pump shell casting, the mold filling and solidification process of the pouring process are simulated by using the numerical simulation software magma. The simulation results are shown in Figure 1 and Figure 2.

From the simulation process of molten iron filling, it can be seen that the top pouring process is adopted for pouring, the molten iron enters the cavity from the pouring system, falls into the bottom of the cavity, and then rises gradually from the bottom, and the filling is stable. The molten iron in the lower part gradually cools down with the molten iron filling process, and the hot molten iron in the upper part feeds the solidification of the molten iron in the lower part. Finally, the solidification of molten iron in the upper part of the vacuum pump shell casting is fed by six risers at the top, realizing the orderly feeding of molten iron.

From the solidification simulation process, it can be seen that the riser of the vacuum pump shell casting finally solidifies during the solidification process, which plays a good role in feeding, and there is no large isolated liquid phase region in the whole process. Local small isolated liquid phase region can compensate for slight shrinkage porosity through graphitization expansion.