There are many research viewpoints about the formation mechanism of anti white mouth defect, such as element area segregation, inoculation decay, grain dissociation and high cooling rate of the final solidification position under specific conditions. These research views on the causes of anti white mouth defects have corresponding theoretical and practical basis, which shows that there are many kinds of anti white mouth defect formation mechanisms, which can not be summarized with a certain theory, but should be analyzed according to the specific situation. Combined with the structural characteristics of horizontal centrifugal casting and the above simulation results of casting temperature field and solid-liquid phase distribution, it can be seen that achieving uniform cooling from the outer wall to the inner wall of horizontal centrifugal casting is an effective method to control the defect location and distribution of horizontal centrifugal casting.

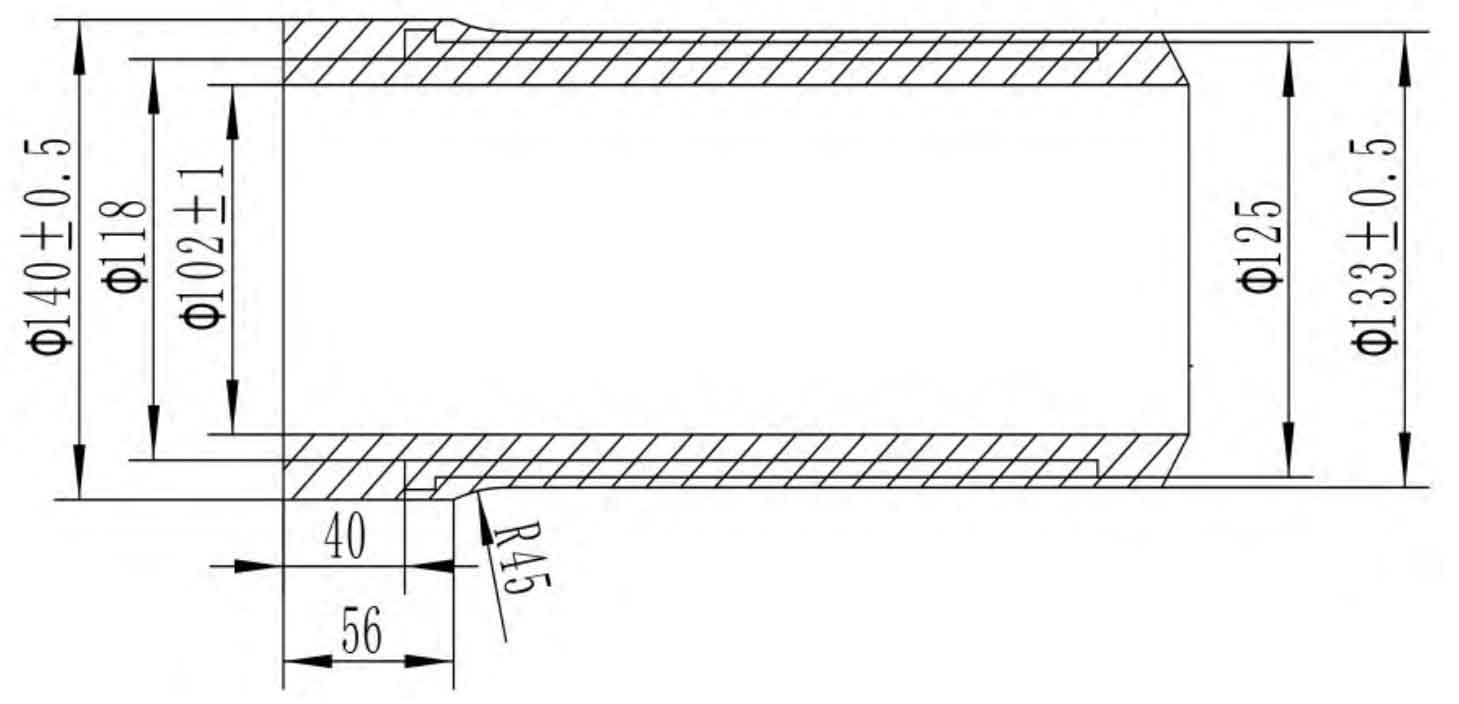

Production practice has proved that the cooling rate in different areas of horizontal centrifugal casting is related to the casting structure, wall thickness and heat dissipation conditions. When the horizontal centrifugal casting is produced according to the initial casting process, the machining allowance of the horizontal centrifugal casting blank is shown in Figure 1. The defect location is about 7mm away from the inner wall of the blank, which affects the machining performance of the horizontal centrifugal casting and the quality of the finished product. According to the simulation results of the initial process plan, the final solidification position is 7-8mm from the wall thickness to the inner wall of the blank. The optimization and improvement plan combines the above research ideas, by increasing the cooling water flow at the wall thickness position, reducing the thickness of the thermal insulation coating at the wall thickness position, increasing the cooling speed at the wall thickness position, improving the consistency of the cooling sequence of the horizontal centrifugal casting, and shortening the solidification time at the final solidification position, Measures such as eliminating the influence of inoculation recession, reducing the depth of the final solidification zone from the inner wall of the blank, eliminating the defects of reverse white casting, and improving the quality and machining performance of horizontal centrifugal casting.

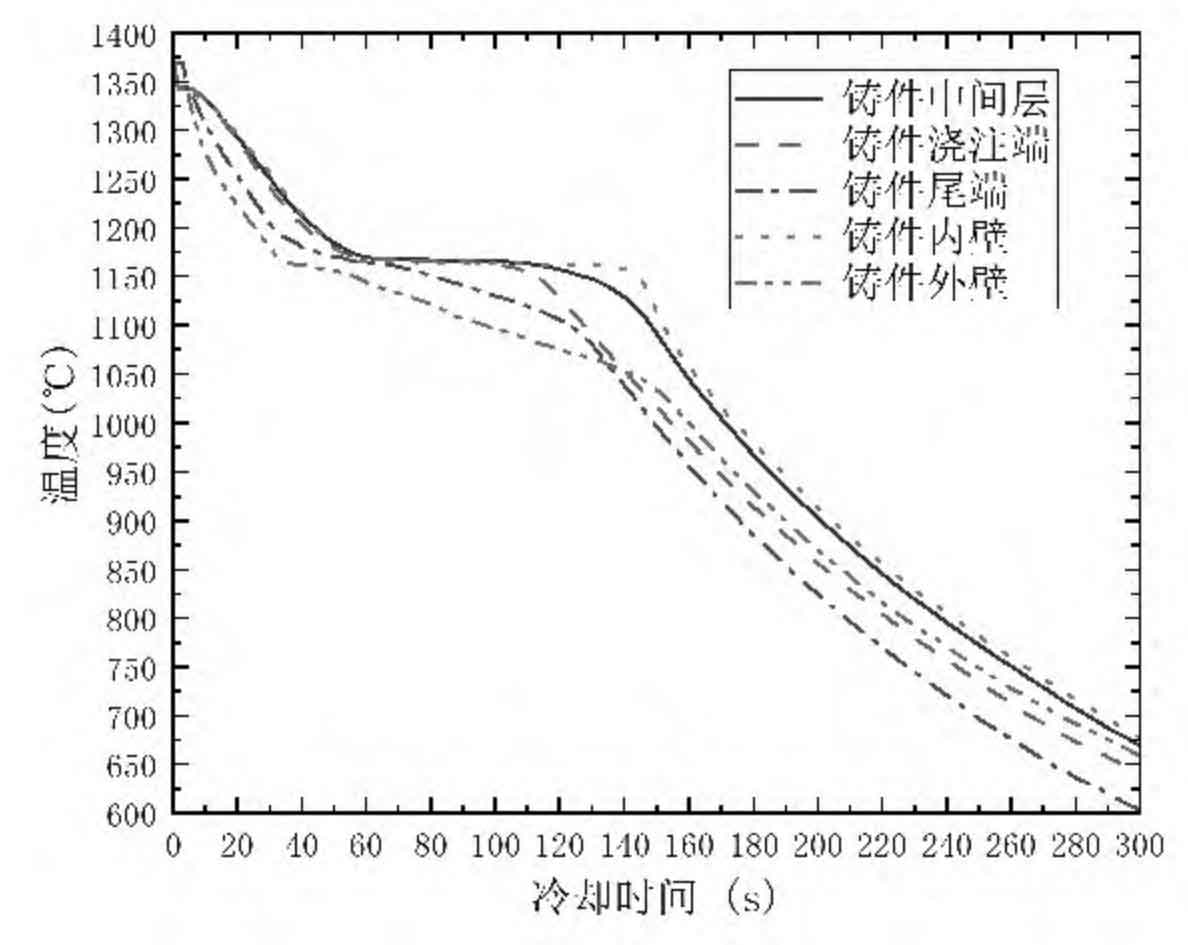

The simulation results of temperature field of horizontal centrifugal casting after process optimization are shown in Figure 2. It can be seen from the figure that the outer wall of horizontal centrifugal casting solidifies first, and the inner wall of horizontal off center casting solidifies last by reducing the thickness of insulation coating at the wall thickness position, increasing the cooling water flow at the wall thickness position, and increasing the cooling speed at the pouring end, so as to achieve uniform cooling from the outer wall to the inner wall of horizontal centrifugal casting.

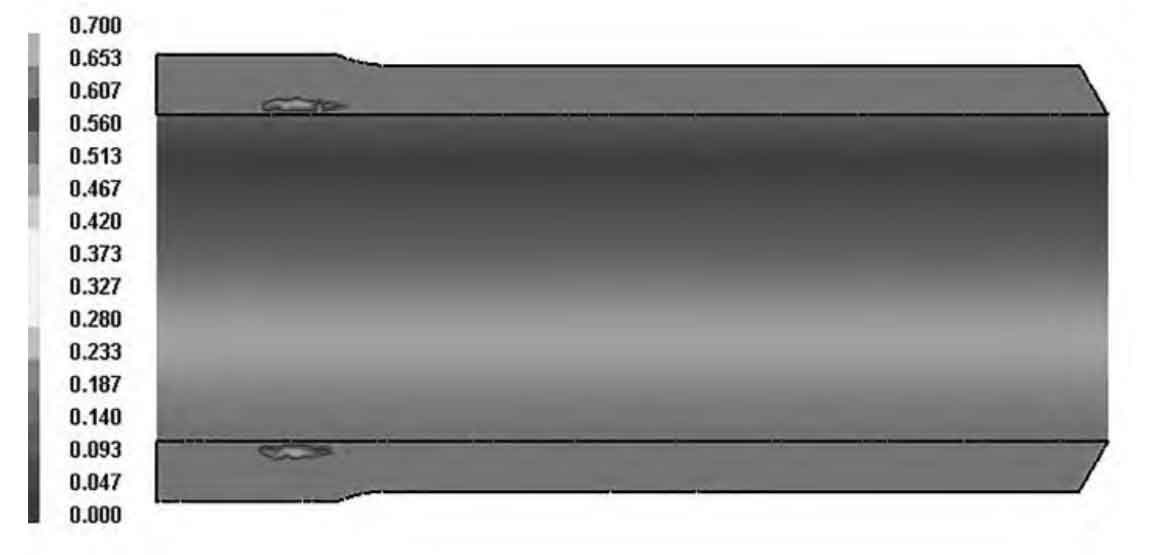

After optimization of process parameters, the distribution of solid and liquid phases in horizontal centrifugal casting at t=120s is shown in Figure 3. The center of the final solidification area in the measurement figure is about 3.5mm from the inner wall of the horizontal centrifugal casting blank. It can be seen from Fig. 2 that the solidification sequence of horizontal centrifugal casting in the improved process plan is better than that in the original process plan. The existing process shall be improved according to the simulation process improvement measures, and the improved process scheme shall be verified in production. After production, the horizontal centrifugal casting shall be subject to metallographic inspection. The qualification rate of horizontal centrifugal casting shall be more than 99.6%, and the qualification rate of finished products shall be 100%, which is consistent with the simulation results.