After the forged knuckle is processed, it is qualified after the sample plate inspection, but after the heat treatment, it is found that the size of the knuckle traction table and the impact table changes greatly. Taking F-type forging knuckle as an example, the dimensional changes of traction table and impact table before and after heat treatment are shown in Table 1.

| Serial number | Upper traction before heat treatment | Lower traction before heat treatment | Upper impact before heat treatment | Lower impact before heat treatment | Upper traction after heat treatment | Lower traction after heat treatment | Upper impact after heat treatment | Lower impact after heat treatment | Upper traction change | Lower traction change | Upper impact change | Lower impact change |

| 0021 | 0.5 | 0.4 | 0.5 | 0.8 | 1.6 | 0.9 | 0.7 | 1.0 | 1.1 | 0.5 | 0.2 | 0.2 |

| 0022 | 0.7 | 0.7 | 0.7 | 0.4 | 1.6 | 1.6 | 0.9 | 0.7 | 0.9 | 0.9 | 0.2 | 0.3 |

| 0024 | 0.5 | 1.0 | 1.0 | 0.7 | 1.2 | 1.8 | 1.1 | 0.9 | 0.7 | 0.8 | 0.1 | 0.2 |

It can be seen from Table 1 that the maximum deformation of the traction table before and after heat treatment of the F-type forging knuckle is 1.1 mm, and the maximum deformation of the impact table before and after heat treatment is 0.4 mm. Based on the analysis of the structure of F-type forged coupler knuckle and the dimensional tolerance zone of traction table (R149+1-0.6) and impact table (R92.50-1), combined with the change of deformation after heat treatment of coupler knuckle, the processing dimensions of F-type coupler knuckle traction table are controlled internally in process. The processing dimensions of traction table are controlled internally according to R149 – 0.5-1 to ensure that after heat treatment, the dimensions of traction table after heat treatment and deformation are within the requirements of R149+1-0.6. In order to ensure that the dimensions of F-type forged knuckle after heat treatment meet the drawing requirements, the secondary inspection process of forged knuckle is added to ensure that the dimensions of forged knuckle sent to the next process are qualified. After later verification, after the internal control of the F-type forging knuckle traction table, the dimension of the F-type forging knuckle traction table meets the requirements of the sample plate inspection clearance.

According to the deformation law before and after the heat treatment of F-type forged knuckle, during the production of CQ type knuckle, the internal control of the processing dimensions of the traction table and the impact table shall be done in advance to ensure that the dimensions of the traction table and the impact table after the heat treatment change within the tolerance range after deformation, as shown in Table 2.

| Serial number | Upper traction before heat treatment | Lower traction before heat treatment | Upper impact before heat treatment | Lower impact before heat treatment | Upper traction after heat treatment | Lower traction after heat treatment | Upper impact after heat treatment | Lower impact after heat treatment | Upper traction change | Upper impact change | Lower impact change |

| 0060 | 0.2 | 0.3 | 0.3 | 0.4 | 0.8 | 0.7 | 0.5 | 0.6 | 0.6 | 0.2 | 0.2 |

| 0062 | 0.3 | 0.2 | 0.4 | 0.4 | 0.6 | 0.5 | 0.6 | 0.5 | 0.3 | 0.2 | 0.1 |

| 0066 | 0.2 | 0.4 | 0.4 | 0.3 | 0.5 | 0.6 | 0.5 | 0.7 | 0.3 | 0.1 | 0.4 |

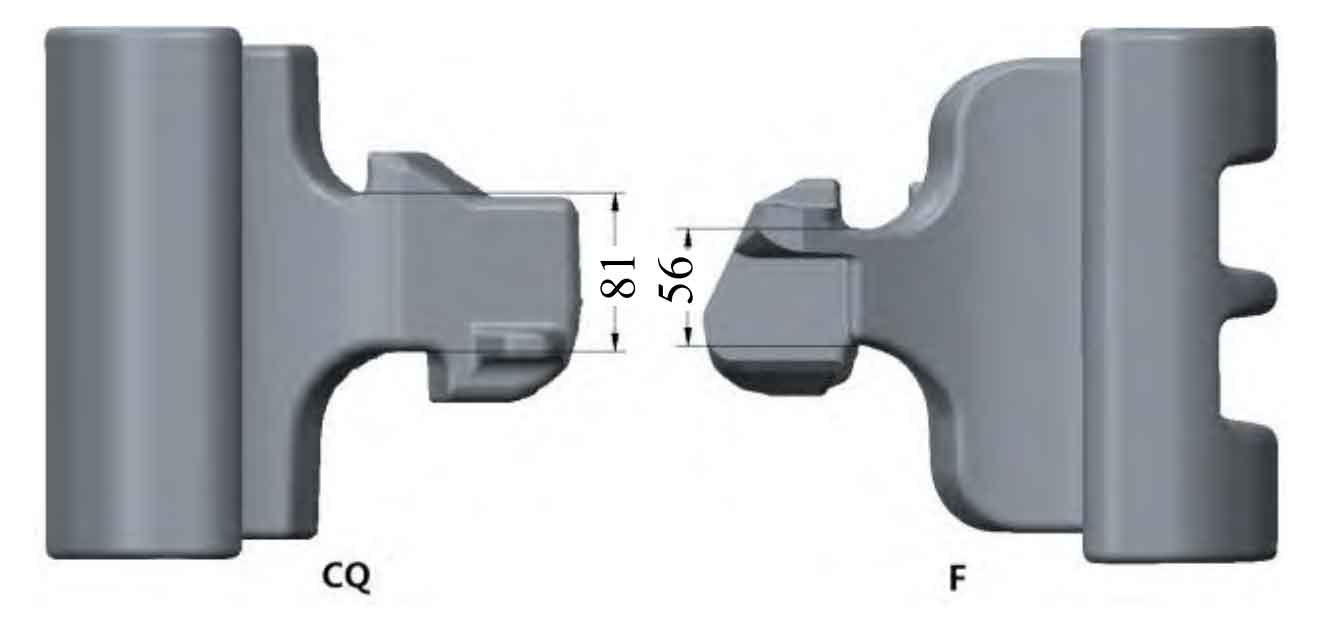

It can be seen from Table 2 that the maximum deformation of the traction table before and after the heat treatment of CQ forged knuckle is 0.6 mm, and the dimensions of the traction table and the impact table after the heat treatment meet the requirements, without dimensional deviation. Through structural analysis of F type and CQ type forged knuckle, it is found that the upper and lower traction platforms of the two forged knuckle have different thicknesses, as shown in the figure. It can be seen from the figure that the size of the upper and lower traction tables of the CQ forged knuckle is larger than the size of the upper and lower traction tables of the F forged knuckle. It can be seen that the deformation of the forging knuckle traction table before and after heat treatment has a certain relationship with the knuckle structure. The larger the size of the forging knuckle upper and lower traction tables, the smaller the deformation.