According to the structure and characteristics of nodular cast iron driving wheel, the parting surface is selected at the center perpendicular to the axis of the part, and the parting is symmetrical. Since the tooth part does not allow the die angle, the core assembly process method is adopted for 19 independent teeth.

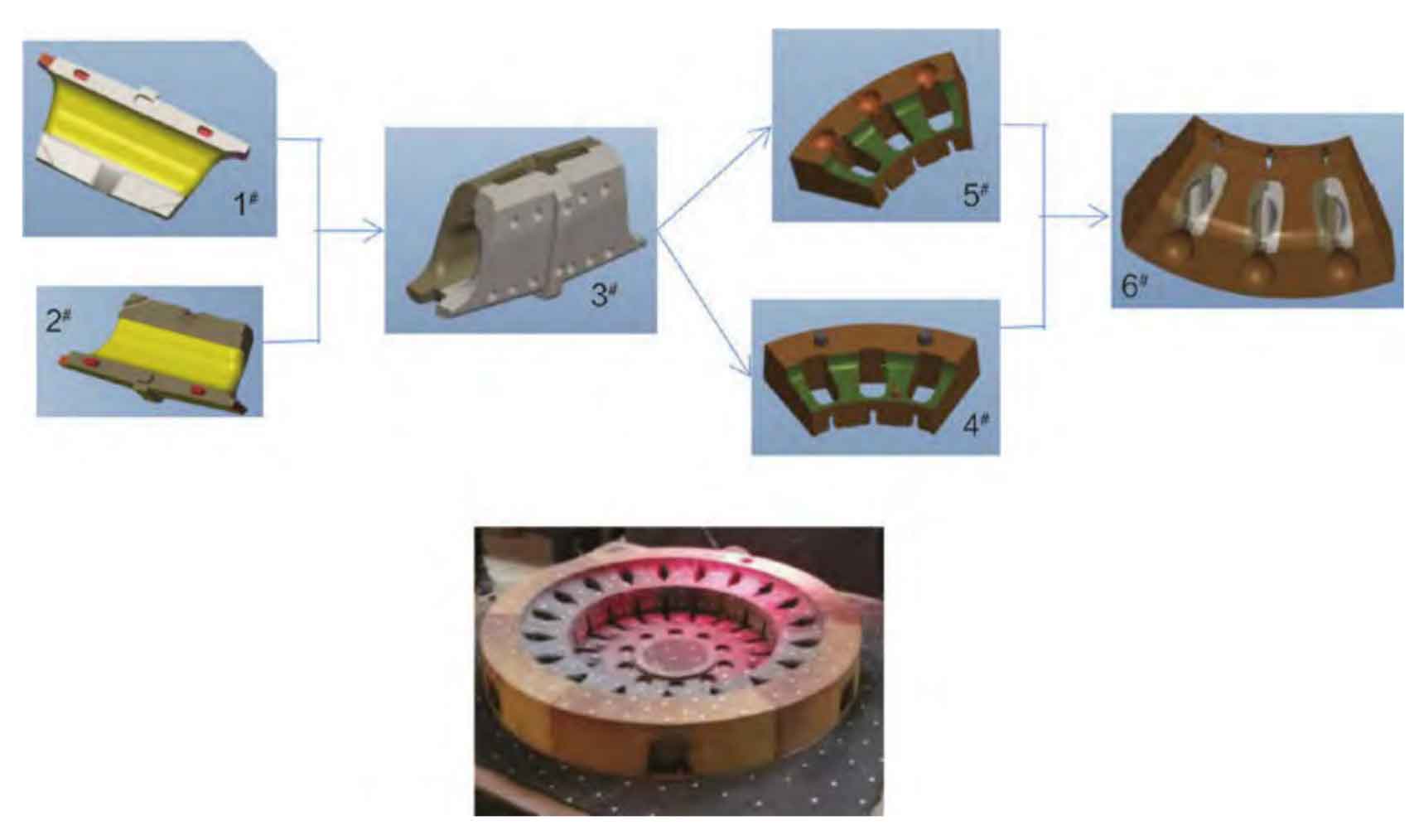

The process scheme of sand core is shown in Figure 2. Each tooth is composed of 1 # and 2 # sand cores and assembled into 3 # sand cores, 3 # sand cores fall into 4 # and 5 # positioning sand cores and assembled into 6 # sand cores, and 6 # sand cores fall into the bottom box. With this process, the seam of nodular cast iron at the tooth is small, and it is easy to ensure the contour of the tooth of nodular cast iron.

The upper and lower sand molds are made of resin sand, and the 1 #, 2 #, 4 # and 5 # sand cores are made of hot-core box coated sand.