1. Modeling process plan

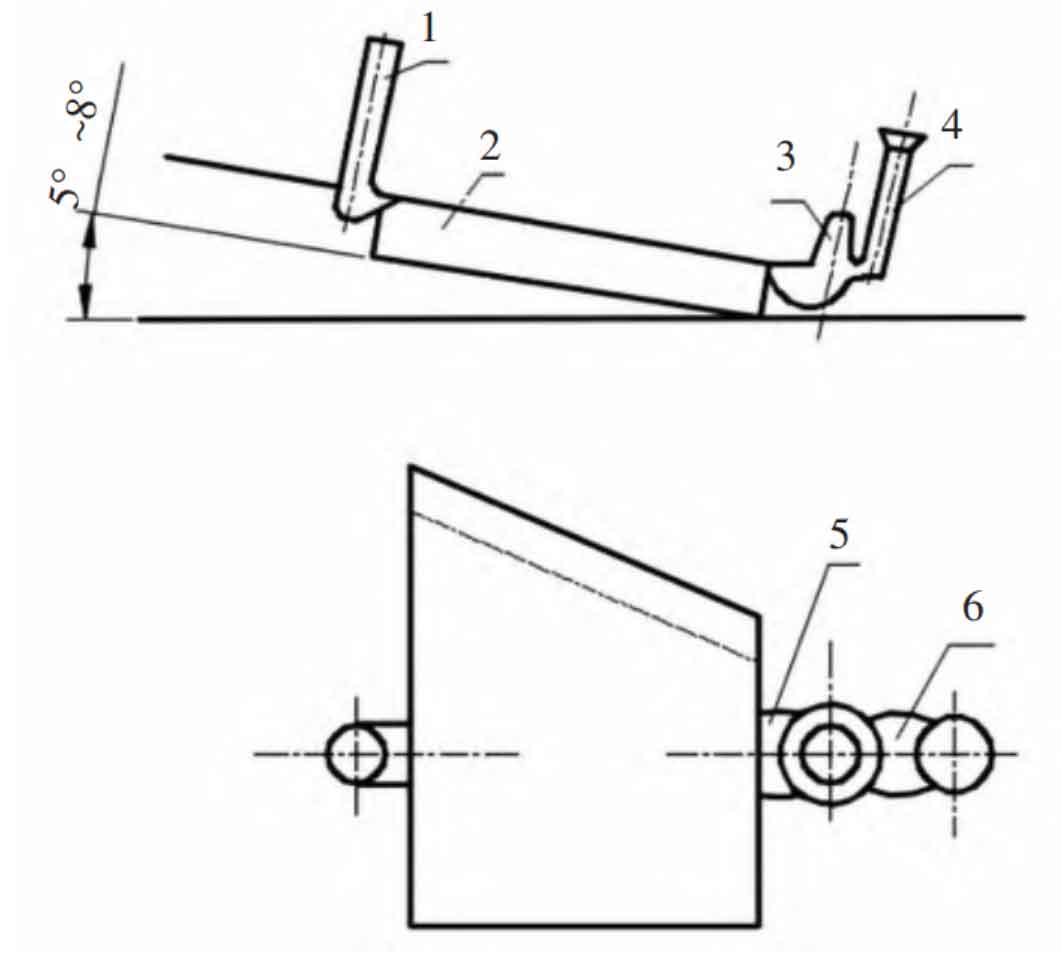

The original molding process plan adopts the clay sand manual molding method, and adopts the bottom pouring inclined pouring process plan, as shown in Figure 1.

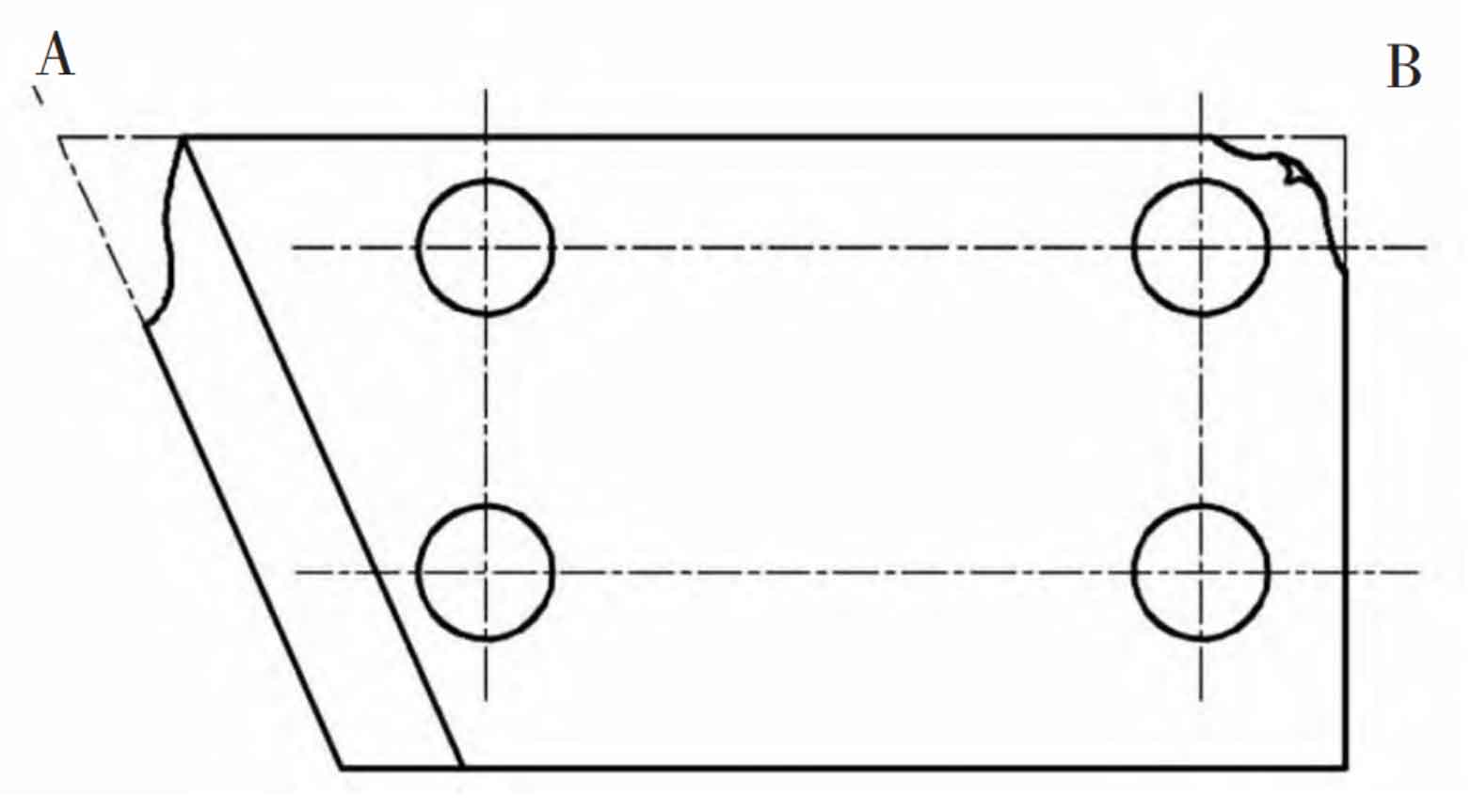

The main defects of the steel castings produced are cold shuts and misfires. The main defects are the sharp corners of the slope A and B as shown in Figure 2. The rejection rate is very high, sometimes as high as 100%. After the horizontal pouring, the effect is still not ideal. The main defects are cold shuts, insufficient pouring, sand inclusion and box expansion.

2. Cause analysis

1) The steel casting is made of medium chromium alloy steel. In order to prevent cracks, it is required to remove and grind the gate when cleaning, instead of cutting with flame. Therefore, the inner gate is opened thinly, the molten steel enters the mold slowly, and the mold filling time is long.

2) Due to the thin wall and large area of the steel casting, the liquid steel rising speed is relatively slow, and the front end of the molten steel into the mold loses too much heat during the inclined bottom pouring.

3) With the flat injection or downward sliding molding process, after the molten steel enters the mold, the molten steel is dispersed in a mixed flow state, the upper surface of the mold is baked for a long time, and the steel castings are more prone to cold shut, sand inclusion and expansion defects.

4) In order to ensure the principle conducive to sequential solidification, the steel castings shall be smooth and free from defects on the surface, and the steel castings shall be free from shrinkage porosity and shrinkage defects on the inside.