The original low pressure casting process of this type of cylinder head adopts the traditional low pressure casting method of raising liquid – filling – pressurization – solidification – pressure relief and cooling. Due to the complex casting structure, it is difficult for the inner runner to shrink to the top plane of the casting, and it is impossible to form a top-down solidification mode, which is easy to form a liquid phase isolated zone. Therefore, a self-feeding non-pressure low pressure casting process is developed and designed, and the gating system of the cylinder head casting is optimized.

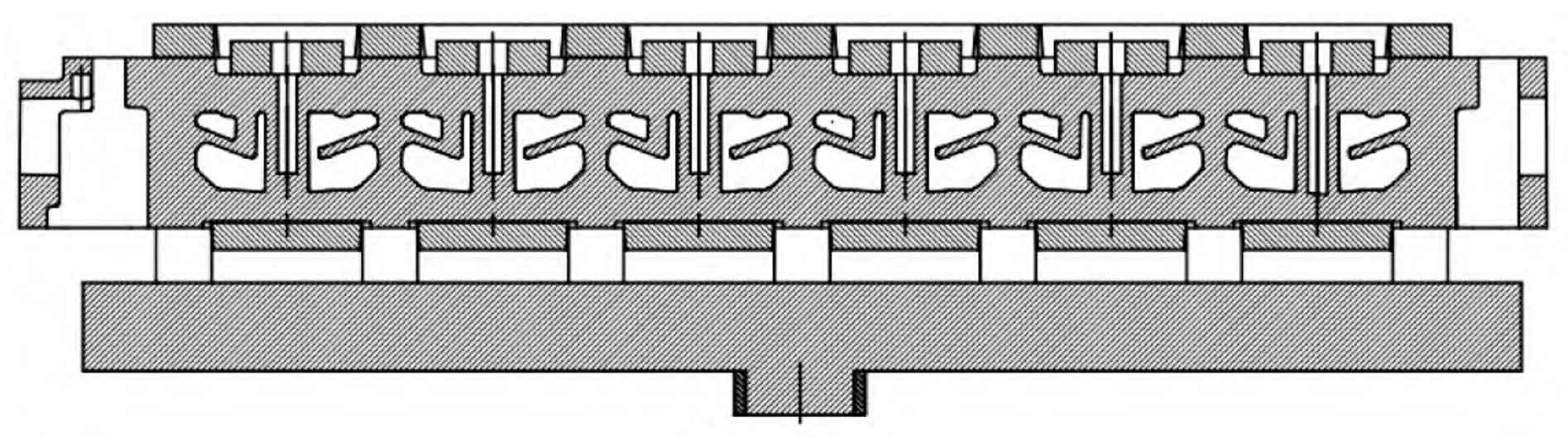

The gating system of the original process of the aluminum alloy cylinder head adopts Φ 45 mm inner runner, which is arranged at the hole position of the main wire. The thickness of the transverse runner is 80 mm. The ceramic filter is used for aluminum liquid filtration, with a liquid weight of 128 kg. The design of the gating system and feeding system is shown in Figure 1.

By using the casting simulation software MAGMA5.4, the casting and solidification process of the cylinder head is simulated and analyzed, and the boundary condition parameters such as aluminum alloy material and resin sand type are set. The aluminum alloy for the cylinder head casting is AlSi7Mg alloy (liquidus temperature 613 ℃, solidus temperature 557 ℃); Furan resin sand is selected for sand mold and sand core; The pouring temperature is 680 ℃; The temperature of sand mold and chill is 20 ℃ at room temperature. At the same time, input the traditional low-pressure pouring pressure curve, the filling rate is 0.001~0.001 2 MPa/s, the stabilizing time is 5~7 s, the pressurizing time is 3~5 s, the holding pressure is 0.016~0.018 MPa, and the holding time is>10 min.

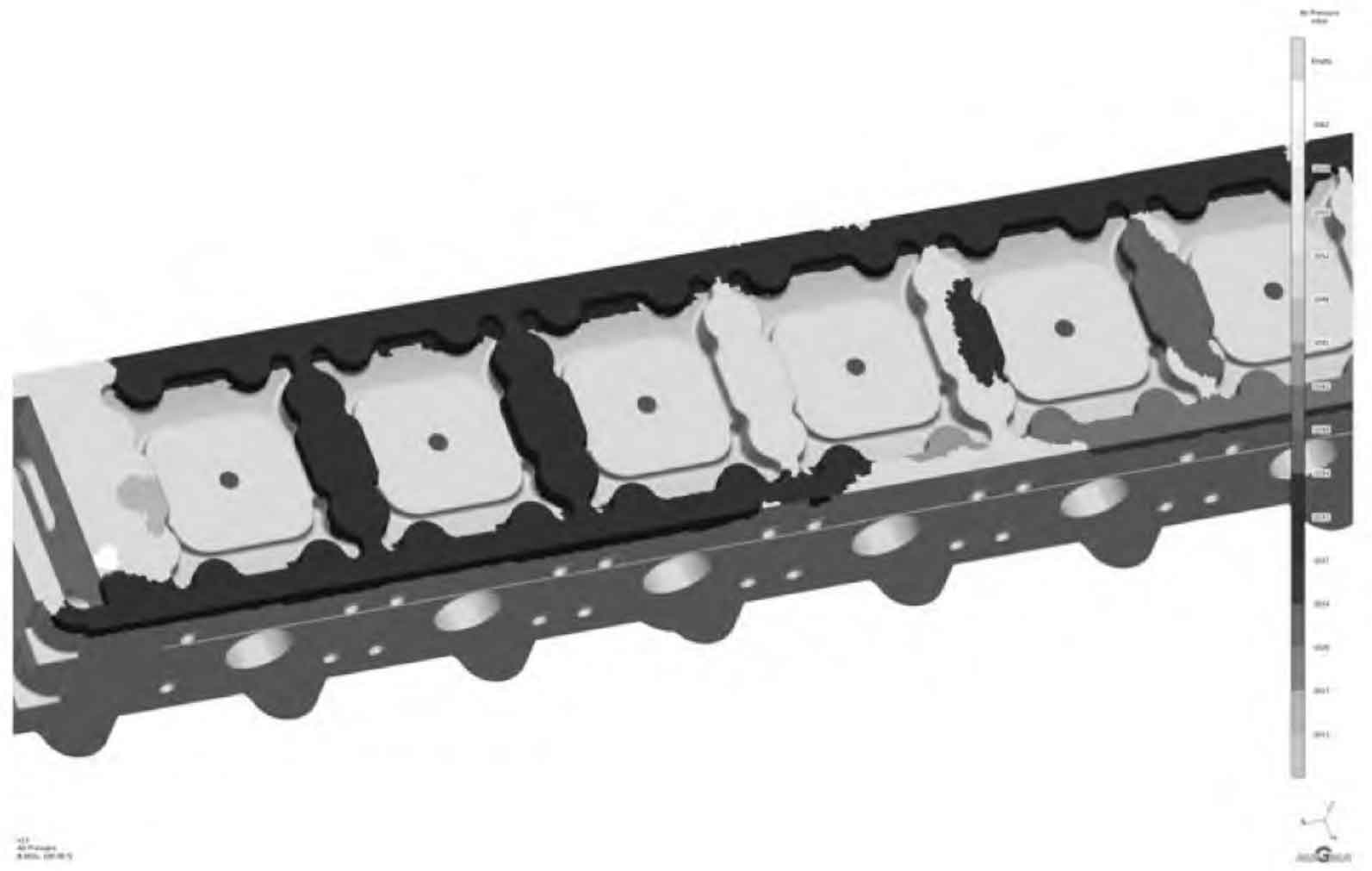

From the simulation results of the pouring process of the cylinder head casting, there is a risk of gas retention and suffocation in the top plane of the cylinder head casting. As shown in Figure 2, the gas pressure is greater than the atmospheric pressure (0.101 3 MPa), and the presence of a large range of cold iron causes the gas in the top plane of the cylinder head casting to be unable to be discharged, resulting in the formation of air holes in the top plane of the cylinder head casting.

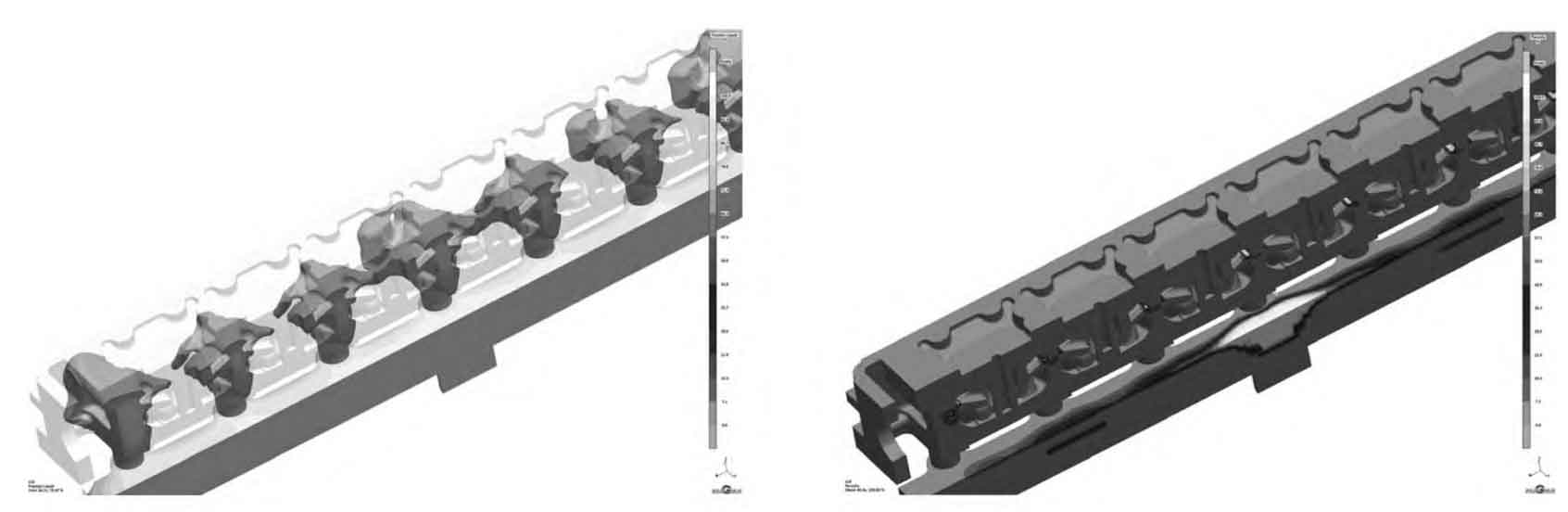

From the simulation results of the solidification process of the cylinder head casting, it can be seen that the inner runner of the cylinder head casting has the feeding capacity, and the cold iron has the rapid chilling capacity, which theoretically forms the solidification direction from top to bottom. However, due to the thick hot spot in the middle of the cylinder head casting, the feeding of the thick part of the cylinder head casting cannot be realized through directional solidification, which ultimately leads to the looseness of the main wire of the cylinder head casting, as shown in Figure 3.