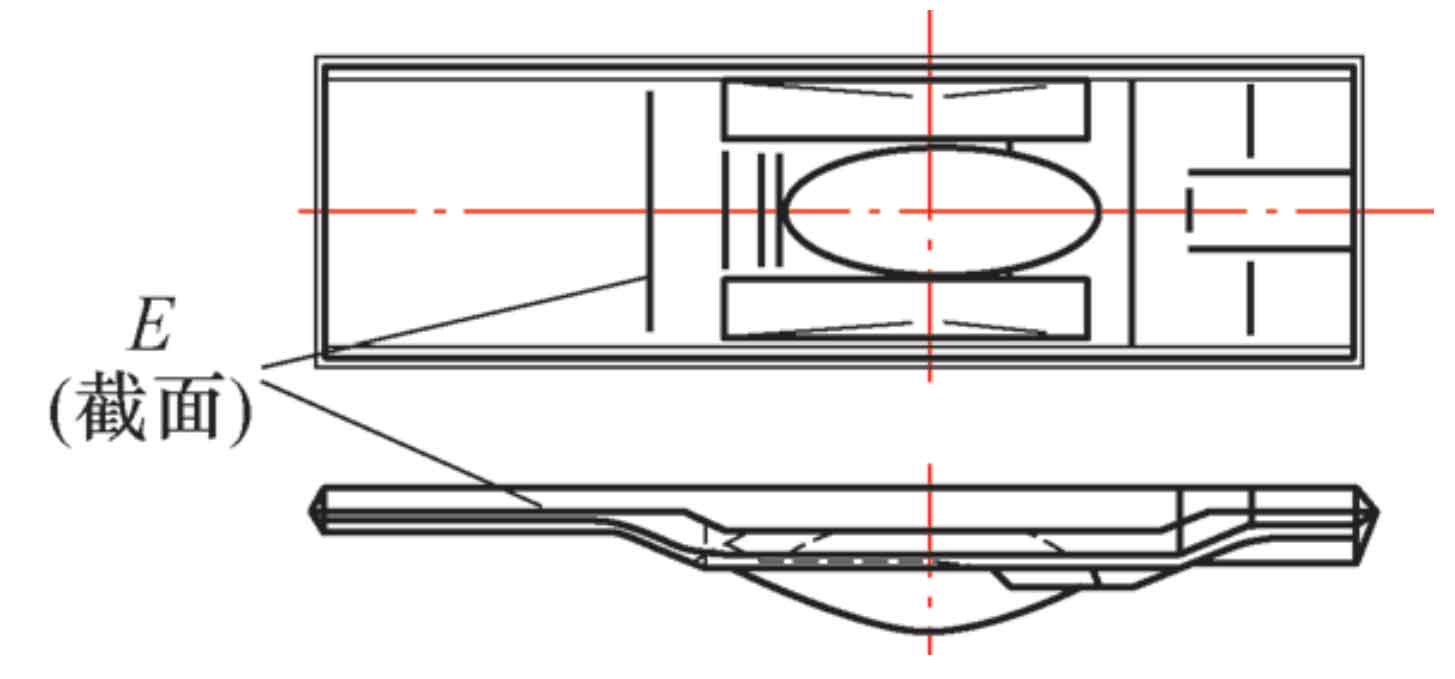

In order to find out the influence of the forging blank on the performance of the finished product, we used ZG30Cr06A square casting blank to analyze the specific parts of a certain type of mining support part. The sampling position of the mechanical properties of the sample is shown in the figure, and the mechanical properties of the sampling positions of the test mining support parts are shown in the table.

| Sampling location | Tensile strength/MPa | Yield strength/MPa | Elongation after fracture (%) | Impact absorbed energy KV/J |

| A | 816 | 621 | 11 | 13.9 |

| B | 814 | 622 | 12 | 14.5 |

| C | 799 | 605 | 8 | 25.1 |

| D | 870 | 675 | 13 | 18.3 |

| E | 871 | 645 | 12 | 16.3 |

It can be seen from the table that the mechanical properties of the part have not been significantly improved, especially the impact properties have even declined. The mechanical properties of the area with large deformation during forging are better. Forging can improve the comprehensive properties of the part, and a certain forging ratio should be guaranteed. Therefore, hot rolled or forged round steel with good quality should be preferred, so that the finished mining support parts will have enough forging ratio.

In addition, the selection of blank has great influence on the quality of forged products. It is necessary to avoid using casting method to make the blank close to the final part shape and then carry out the forging process. Because its forging is relatively small, it can not guarantee the forging penetration, and there may be a large number of as-cast structure residues. If there are shrinkage holes, pores and other defects in the ingot, there will be a great probability of regular shrinkage holes, pores and other defects in the original ingot, and then grow into irregular cracks, or shrinkage holes, pores and other defects are not in the forging deformation zone, Defects still exist after forging, affecting the toughness and fatigue strength of forgings. The comprehensive mechanical properties of such forgings will not be greatly improved, or even reduced, than that of castings. In addition, due to the lack of forging, there is a certain metal flow line outside the part, and the grain structure is good, while the internal part is still in the as-cast structure due to the lack of forging deformation, which will bring difficulties to the subsequent heat treatment and is not easy to control. After the heat treatment, there will be large mechanical property differences in different parts of the part, which will bring quality risks to the product.