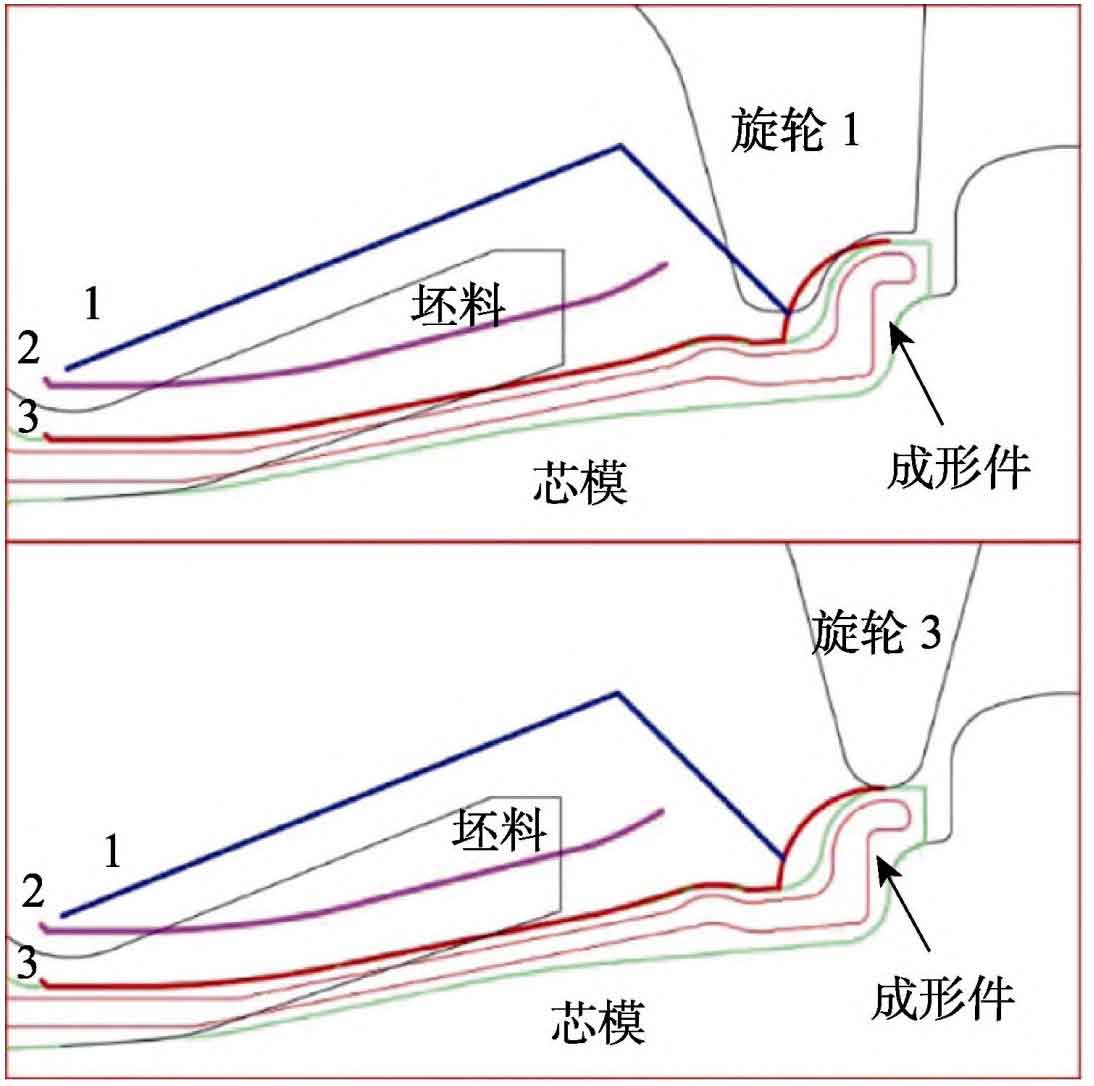

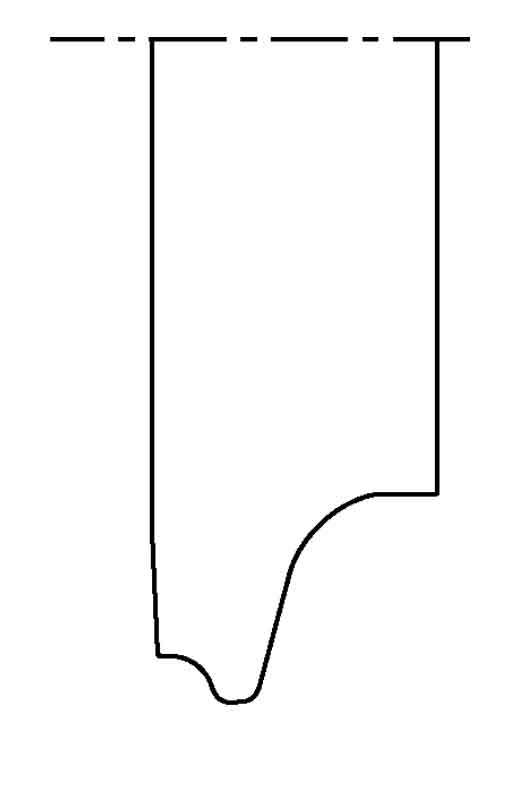

The geometry and size of the cast spinning wheel of the aluminum alloy wheel directly affect the contact area between the cast spinning wheel and the blank and the spinning pressure. In order to ensure sufficient deformation of the material in the forming process of the inner wheel flange, ensure the uniformity of deformation and inhibit the metal backflow, a special-shaped (conformal) spinning wheel as shown in Figure 1 is designed according to the core die terminal structure, and the shape of the working part of the casting spinning wheel is consistent with the shape of the outer side of the inner wheel flange. On the basis of the existing forming scheme (process), an improved forming scheme is proposed by replacing the original spinning wheel 1 with a special-shaped (conformal) spinning wheel. The principle of the improved forming scheme is shown in Figure 2a.

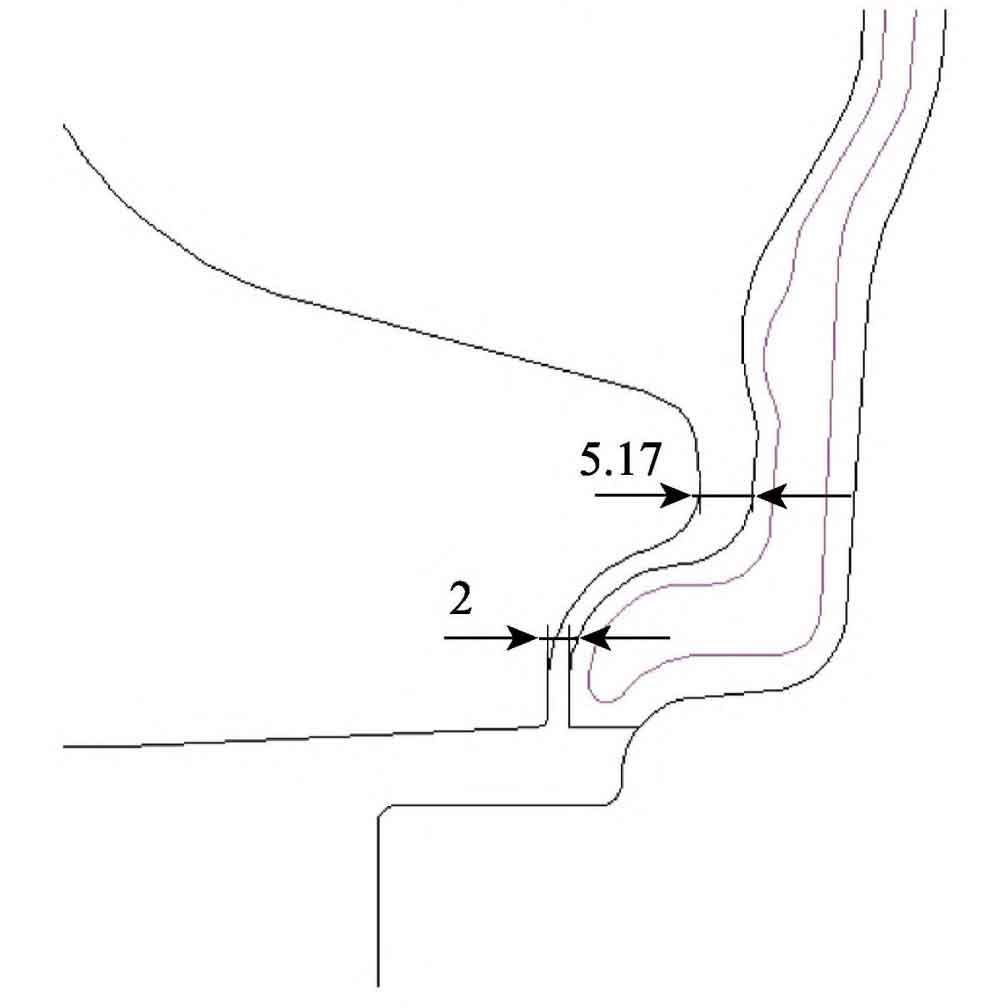

In the improved forming scheme, when the casting roller 2 is about to exit, the profile wheel moves to the corner position at the end of the mandrel, and the final position of the profile wheel is shown in Fig. 2b. That is, in the process of forming the inner rim, the special-shaped roller 1 and the roller 3 work together to make the material fully extrude to the fillet, ensuring that the extrusion deformation is sufficient and the structure is refined.

On this basis, starting from the hump forming part, the feed speed of the casting roller 3 in the improved scheme considers two cases.

| Spinning forming scheme | Spinning wheel feed speed/(mm · min ^ -1) Spinning wheel 2 | Spinning wheel feed speed/(mm · min ^ -1) Spinning wheel 3 |

| Existing process (scheme) | 500 | 500 |

| Improvement plan A1 | 500 | 500-1000 |

| Improvement plan A2 | 500 | 500 |

1) Option A1. During the forming process, the feed speed of the casting spinning wheel 3 is reduced from 500 mm/min to 100 mm/min, that is, the end spinning wheel is slowly fed. The purpose of reducing the feed speed of the casting roller 3 is to ensure that there is enough time to complete the deformation of the inner rim.

2) Option A2. The feed speed of casting spinning wheel 3 is always 500 mm/min. The feed parameters of the spinning wheel of the improved forming scheme are shown in the table.