1. Determination of pouring speed

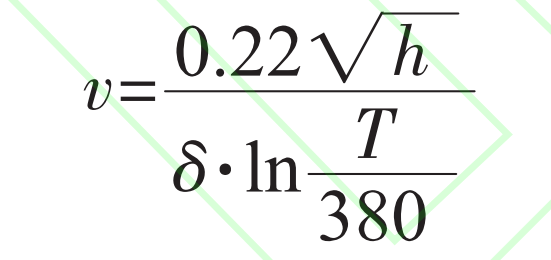

The pouring speed was calculated using the Kalgin formula in the experiment:

Where: v is the pouring speed of molten metal for mold filling, cm/s; H is the height of the fixed disk investment casting, cm; δ Is the wall thickness of the fixed disk investment casting, cm; T is the pouring temperature of the alloy, ℃. The pouring speed is calculated to be v=266.105mm/s. Considering the influence of parameter calculation, the pouring speed is simulated at a speed of 300mm/s.

2. Main process parameters

Referring to relevant experiments, the liquidus temperature is taken as 1494 ℃, and the solidus temperature is taken as 1425 ℃; The entire mold shell has a thickness of about 6 mm and is a sealed solid consisting of 6 layers of quartz sand refractory and silica sol. Considering the quality and efficiency of fixed disk investment casting, the entire pouring process is completed in air using a top pouring method, with the mold shell preheated to 1000 ℃ at the beginning; Maintain a pouring speed of 300 mm/s and pour at a temperature of 1580 ℃. The fixed disk investment casting is cooled by natural cooling; Pouring direction: Set the gravity direction to the negative x direction.