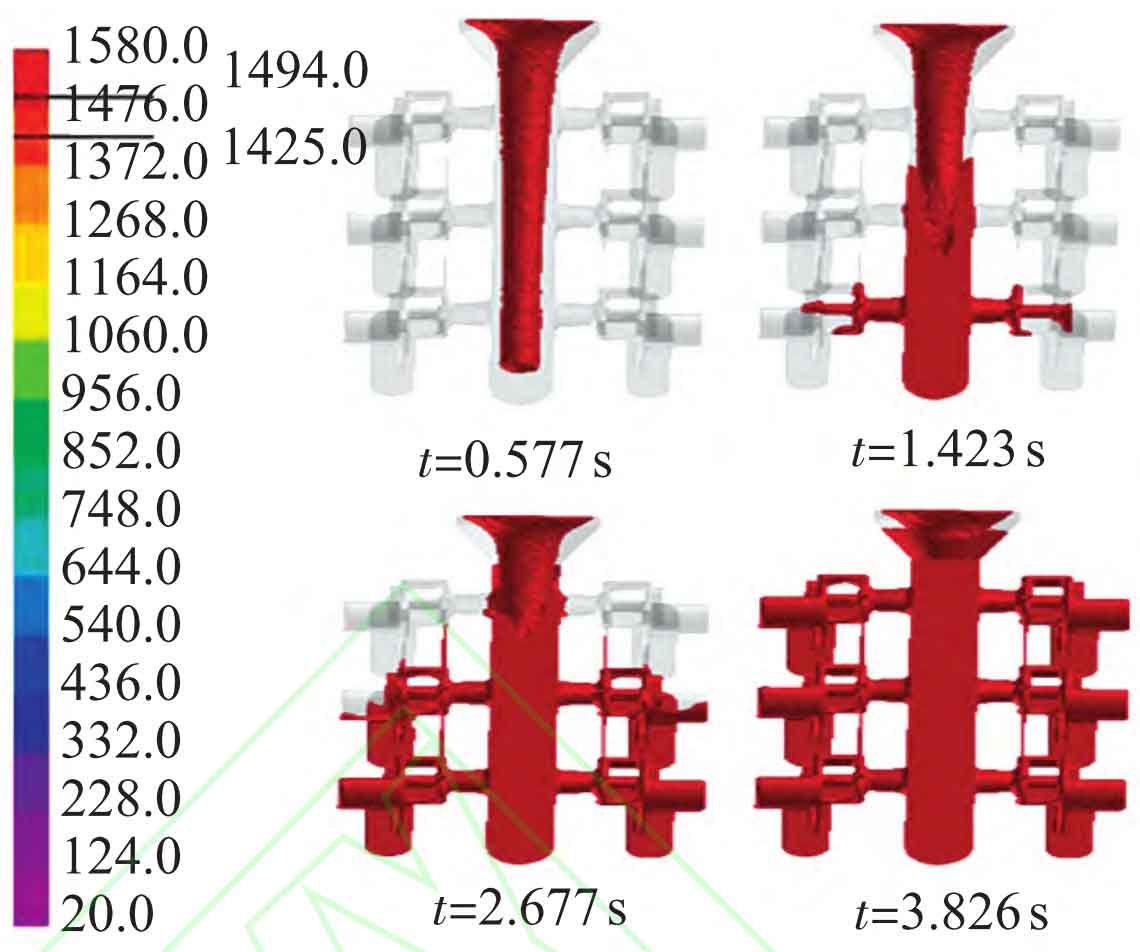

Fixed disk investment castings have different filling states during the initial process plan filling process. The filling state diagram for the first 4 seconds is shown in Figure 1.

From Figure 1 and the data, it can be seen that the filling process of the initial scheme is generally relatively smooth, with no severe impact of liquid metal on the inner wall of the mold shell during the process, and no local damage to the fixed disk investment casting caused by excessive pouring speed. Before 1.423 s, the liquid metal filled the sprue and entered the first group of workpiece cavities, filling was relatively stable, and by 3.826 s, the liquid metal was nearly fully filled.

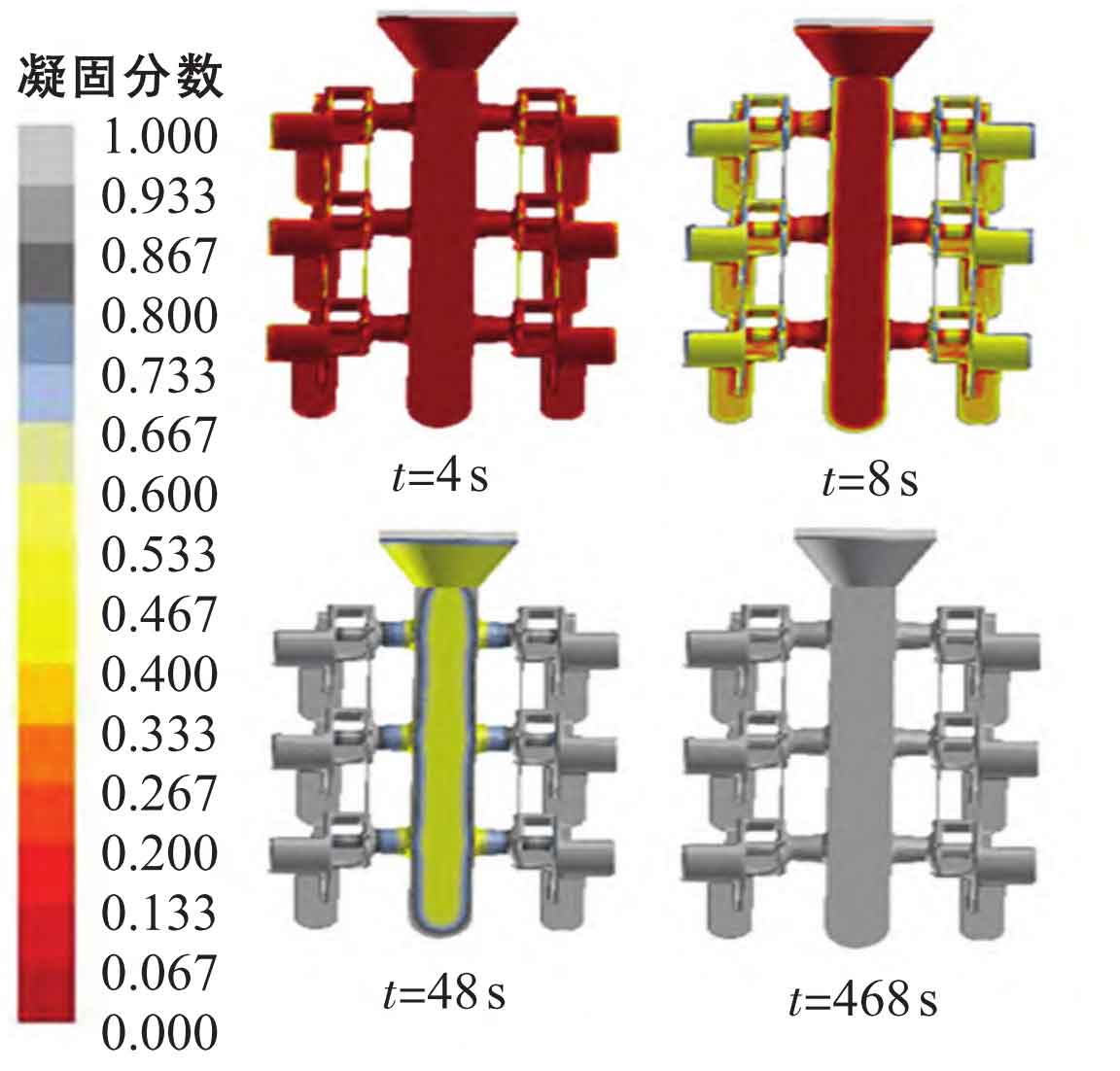

The solidification condition of the fixed disk investment casting during the pouring process directly affects the quality of the fixed disk investment casting product. The solidification rate state diagram of the initial process plan is shown in Figure 2. As can be seen from the figure, the pouring system begins to solidify at 48 seconds, and during the entire solidification process, the fixed disk investment castings are basically solidified in a sequence from the workpiece to the inner sprue. This solidification sequence is conducive to the solidification and molding of the fixed disk investment castings, as well as to the production of high-quality fixed disk investment castings. At 4 s, the outermost part of the fixed disk has already begun to solidify. At 48 s, the solidification fraction of the workpiece is approximately 1.0, indicating that the workpiece has basically completed solidification. The complete solidification of the entire pouring system takes 468 seconds, followed by natural cooling.

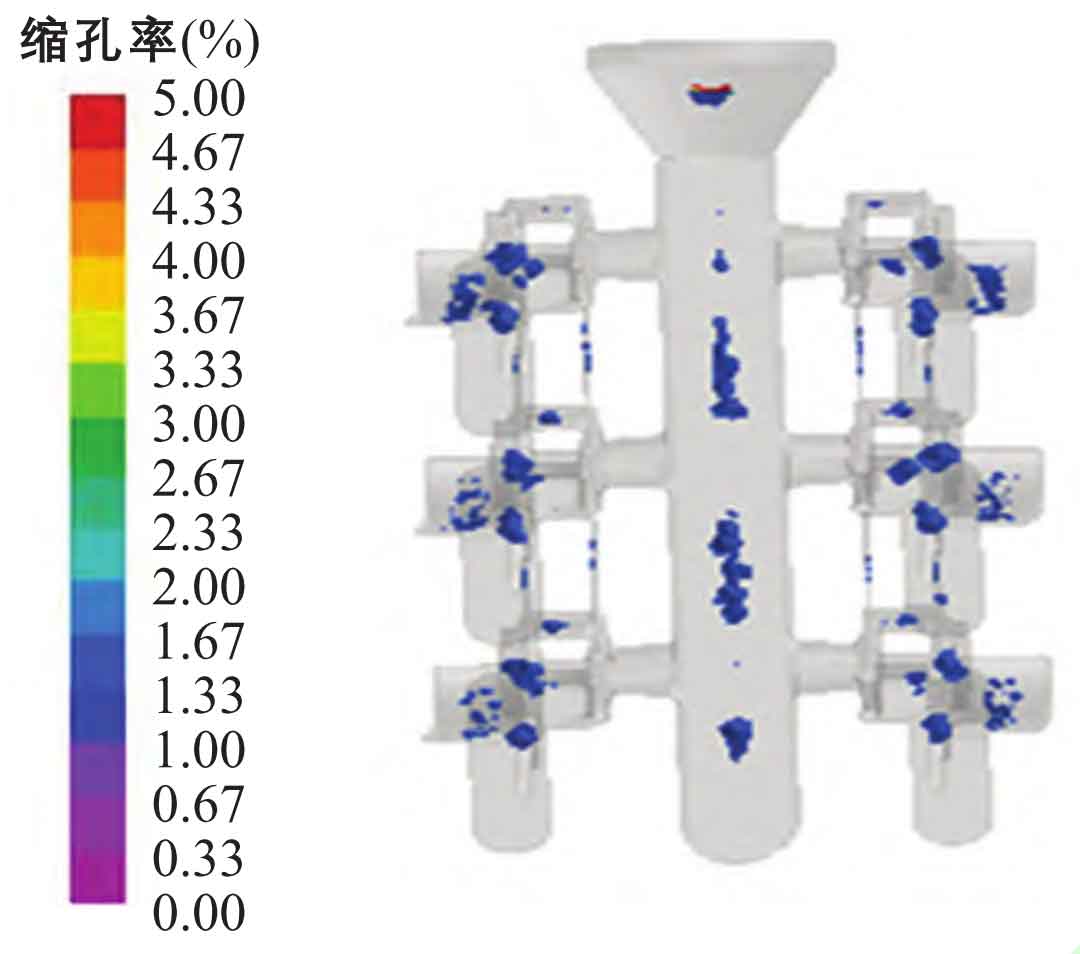

The initial process shrinkage distribution diagram is shown in Figure 3. The distribution of shrinkage cavities with a volume fraction greater than 1.0 predicted using numerical simulation technology under the initial process scheme of the fixed disk. From the analysis and simulation results, it can be seen that the phenomenon of shrinkage and porosity in the curved surface of the part is relatively serious, and this phenomenon occurs in the main runner and the curved part of the part. The existence of shrinkage porosity and porosity can have a negative impact on the quality of fixed disk investment castings, and in severe cases, it will directly lead to product scrapping. In actual production, it is necessary to avoid this problem as much as possible [8]. The numerical simulation results are the same as the causes of product defects in the actual production of the initial process plan, verifying the feasibility of the simulation analysis.