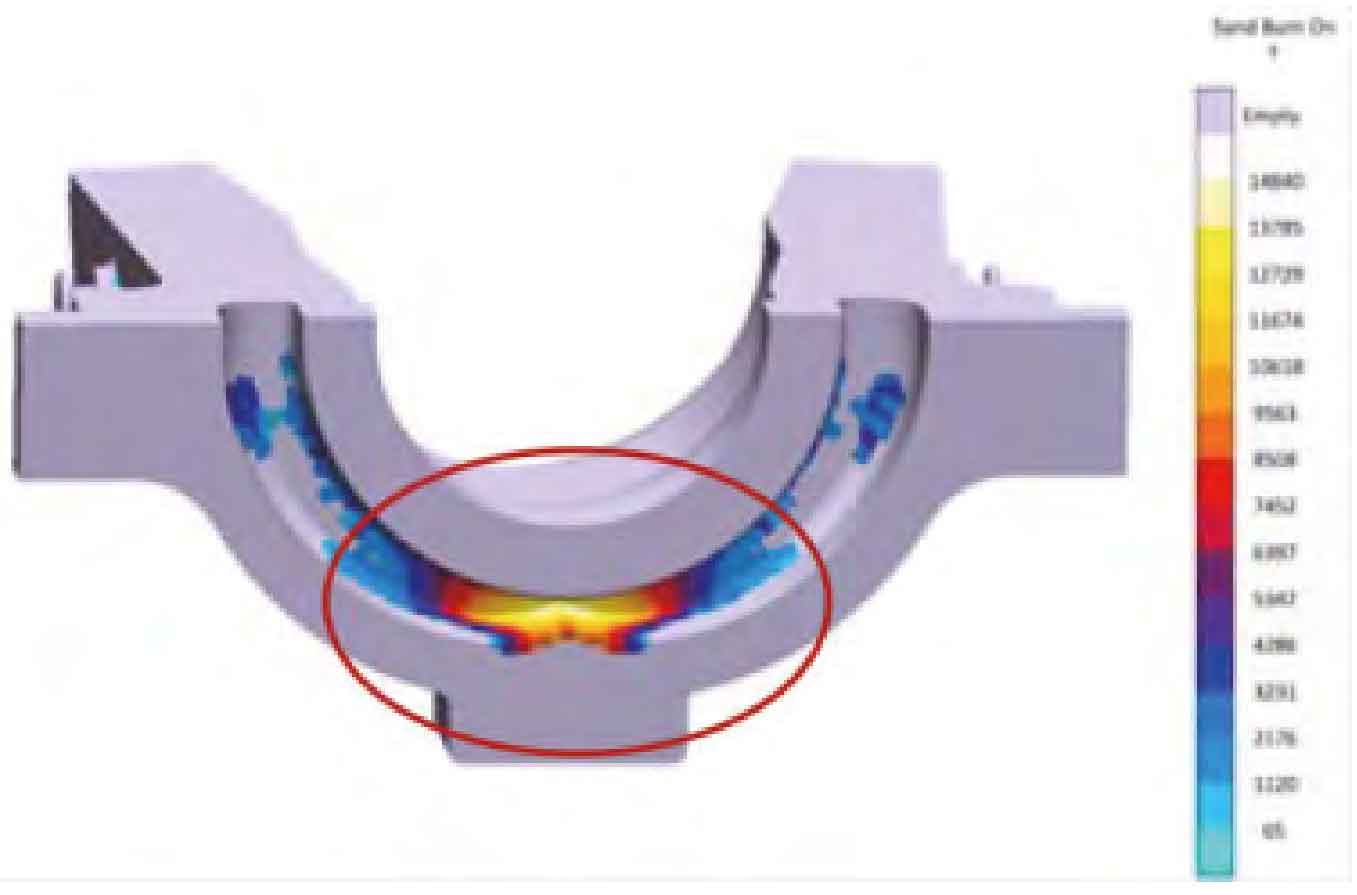

Due to the small space and large wall thickness in the steam inlet chamber of the inner chamber of the intermediate pressure inner cylinder, the surface of the sand mold after pouring is subjected to long-term high-temperature baking of the molten steel, and the defects of sand sticking and slag inclusion are easily formed in the chamber; The steel casting has a large wall thickness and a large hot spot at the root of the wall riser, which is prone to sand adhesion, as shown in the figure. Therefore, the sand mold for the steel casting part is prepared with chrome iron ore sand with high fire resistance. In particular, the sand core of the steam inlet chamber is vibrated and compacted using a vibrating sand machine to ensure compactness, so as to ensure that the molding sand here has a high fire resistance.

A tie bar is provided at the back flange of the steel casting to reduce stress concentration caused by wall thickness differences during solidification; The middle split is provided with exhaust holes and slag collecting grooves to enhance the exhaust capacity.