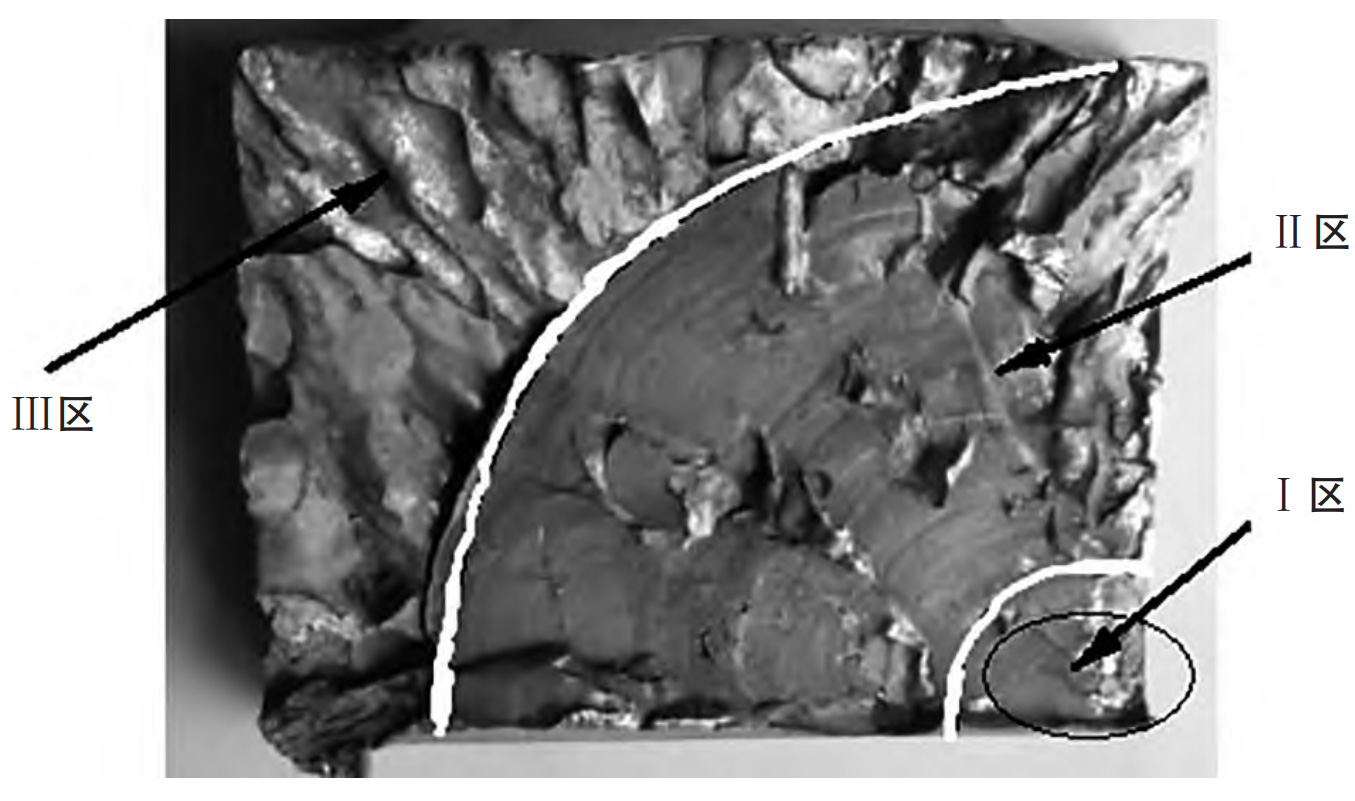

Based on the above investigation, it is determined that the fracture at the axle hole of the front support steel casting is fatigue fracture. There are two reasons for this: firstly, improper casting process, and secondly, improper heat treatment process.

1. Improper casting process

Due to the small length and size of the riser neck, improper position, and fast cooling speed, defects such as shrinkage porosity and cracks occur at the shaft holes with thicker wall thickness during casting of the front support of the steel casting. Due to the lack of testing at this location, defective products were assembled into the finished boom product. This part is a crucial load-bearing part of the boom, which forms fatigue fracture under alternating loads.

2. Improper heat treatment process

Due to the large thickness and insufficient normalizing and insulation time of the faulty area, the Weinstein structure was not effectively eliminated, resulting in coarse grains, significantly reduced plasticity and impact toughness, and ultimately fracture.