Casting shrinkage is a complex phenomenon influenced by various factors that impact the solidification and cooling processes during metal casting. Understanding the underlying science behind casting shrinkage is essential for improving the quality and reliability of castings. This article provides a comprehensive analysis of the science behind casting shrinkage, exploring the mechanisms, factors, and principles involved in this phenomenon.

- Solidification and Cooling Behavior: Delve into the solidification and cooling behavior of molten metal during casting processes. Understand the nucleation and growth of solid phases, the formation of dendritic structures, and the development of grain boundaries. Explore the impact of cooling rates on the microstructure and subsequent shrinkage behavior.

- Thermal Contraction and Volume Change: Explore the thermal contraction and volume change that occur during the solidification and cooling of molten metal. Understand how the density variation with temperature affects the overall casting dimensions and the occurrence of shrinkage defects. Learn about the role of alloy composition, phase transformations, and thermal expansion coefficients in determining shrinkage behavior.

- Solidification Shrinkage and Liquid Shrinkage: Investigate the two main types of shrinkage in casting processes: solidification shrinkage and liquid shrinkage. Understand how solidification shrinkage occurs due to the reduction in volume during the phase change from liquid to solid. Explore the mechanisms of liquid shrinkage, including the contraction of the liquid metal as it cools and the compaction of the dendritic network.

- Influence of Alloy Composition: Learn about the influence of alloy composition on casting shrinkage. Understand the role of eutectic and peritectic reactions, alloy solidification range, and alloying elements in affecting the shrinkage behavior. Explore the impact of impurities, segregation, and microstructure on the susceptibility to shrinkage defects.

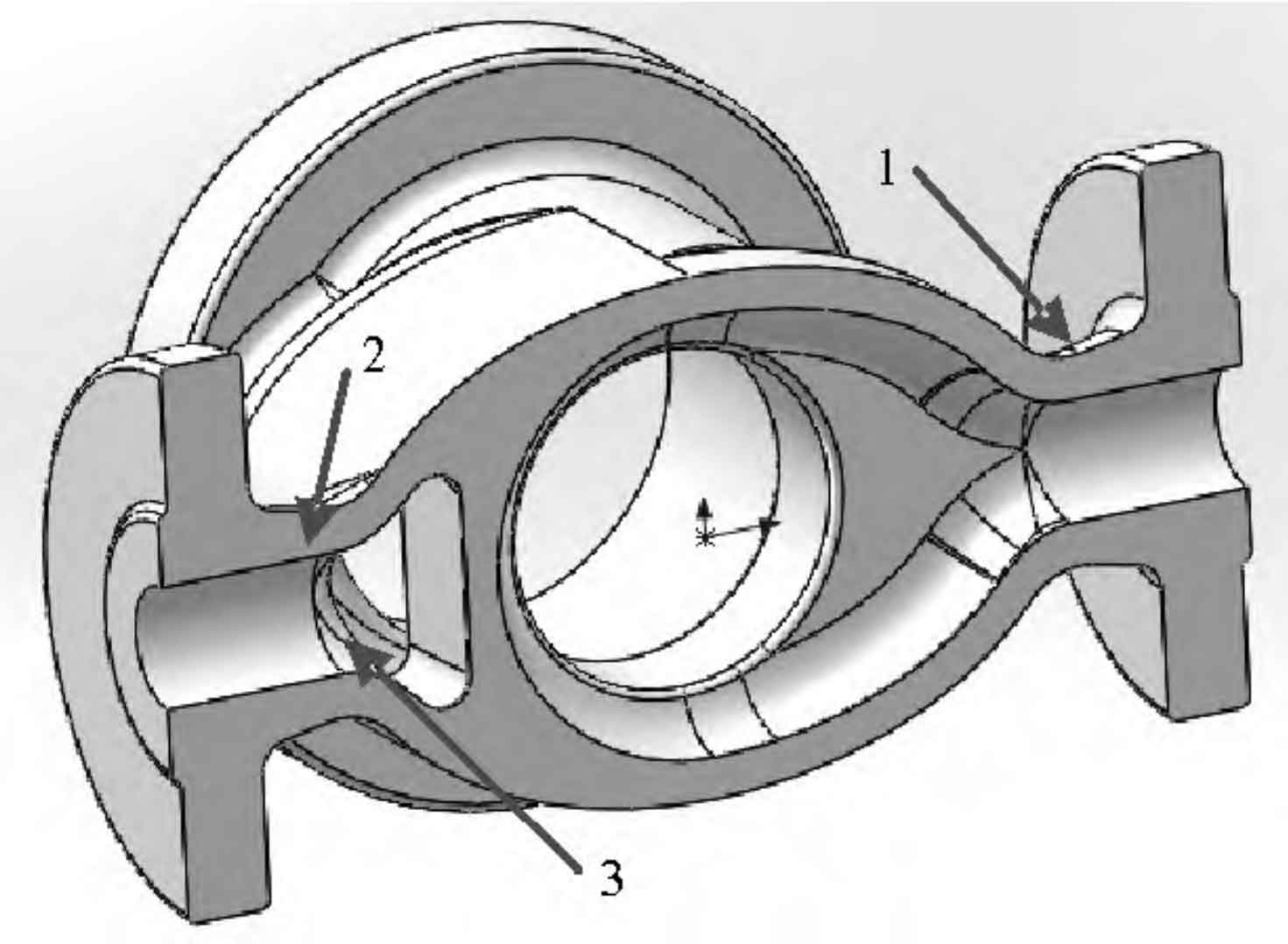

- Factors Affecting Shrinkage Defects: Identify the various factors that can contribute to shrinkage defects in castings. Explore the influence of pouring temperature, cooling rate, mold material, mold design, and gating system on the occurrence and severity of shrinkage. Understand how these factors affect the solidification behavior, feeding capabilities, and overall shrinkage resistance of the casting.

- Simulation and Modeling Approaches: Discover the use of simulation and modeling techniques in predicting and analyzing casting shrinkage. Learn about the application of solidification simulation software, such as finite element analysis (FEA) and computational fluid dynamics (CFD), in understanding the shrinkage behavior and optimizing process parameters.

By comprehensively analyzing the science behind casting shrinkage, foundry professionals, engineers, and researchers can gain insights into the complex mechanisms and factors influencing shrinkage defects. This knowledge can be utilized to optimize casting processes, improve alloy design, and implement effective strategies to minimize shrinkage and enhance the quality of castings.