Casting shrinkage defects can significantly impact the quality and reliability of castings. Minimizing these defects requires the implementation of best practices and techniques throughout the casting process. This article explores the best practices and techniques that can effectively reduce casting shrinkage defects and enhance the overall quality of castings.

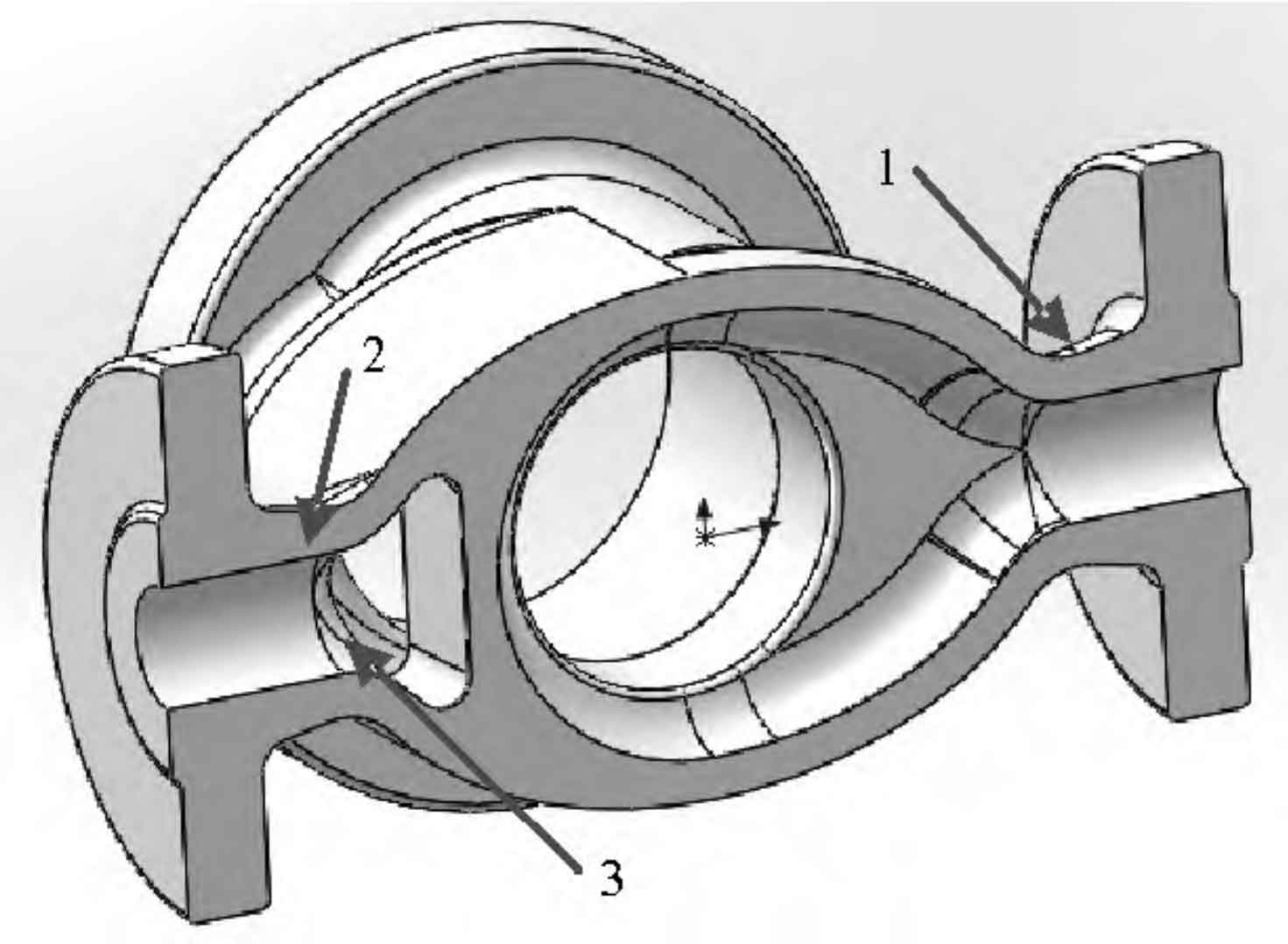

- Optimized Gating and Riser Design: Proper gating and riser design play a crucial role in minimizing casting shrinkage defects. Optimize the gating system to ensure a smooth and controlled flow of molten metal, promoting uniform solidification. Design risers in such a way that they provide adequate feeding and compensate for the shrinkage during solidification.

- Controlled Pouring Temperature: The pouring temperature of the molten metal can significantly affect casting shrinkage. Maintain a controlled pouring temperature within the recommended range to optimize solidification behavior and reduce the risk of shrinkage defects. Avoid excessively high temperatures that can lead to rapid solidification and shrinkage porosity.

- Optimal Cooling Rate: The cooling rate of the casting influences the solidification process and the occurrence of shrinkage defects. Control the cooling rate by proper design of the mold, optimized placement of cooling channels, and appropriate mold materials. Gradual and controlled cooling helps to minimize thermal gradients and shrinkage-related stresses.

- Feeding Systems and Risers: Implement effective feeding systems and risers to ensure sufficient molten metal supply during solidification. Use risers strategically to provide a continuous supply of molten metal, compensating for the volume reduction due to shrinkage. Consider the size, shape, and placement of risers to optimize their feeding efficiency.

- Alloy Selection and Modification: The choice of alloy and its composition can impact the susceptibility to shrinkage defects. Select alloys with lower solidification shrinkage and better feeding characteristics. Consider modifying the alloy composition by adding elements or using grain refinement techniques to control the solidification behavior and reduce shrinkage defects.

- Mold and Core Design: Optimize the design of the mold and cores to minimize shrinkage defects. Ensure proper venting to allow for the escape of gases during solidification. Use high-quality refractory materials and coatings to improve mold and core properties, reducing thermal gradients and enhancing solidification control.

- Process Monitoring and Control: Implement robust process monitoring and control techniques to identify and address potential shrinkage defects during casting. Utilize non-destructive testing methods, such as X-ray imaging and ultrasonic testing, to detect internal defects. Continuously monitor and adjust process parameters to optimize solidification behavior and minimize shrinkage.

- Simulation and Modeling: Utilize advanced simulation and modeling tools to predict and analyze casting shrinkage. Solidification simulation software can provide insights into the solidification behavior and help optimize process parameters. Modeling techniques enable the evaluation of different design and process scenarios before actual casting, reducing the risk of shrinkage defects.

- Quality Assurance and Inspection: Implement stringent quality assurance measures and inspection techniques to ensure the detection and control of shrinkage defects. Conduct visual inspections, dimensional checks, and non-destructive testing to identify and address any shrinkage-related issues.

By incorporating these best practices and techniques, foundries can minimize casting shrinkage defects and improve the overall quality of their castings. It is essential to continuously evaluate and optimize the casting process to reduce shrinkage-related risks and enhance the integrity and performance of the final products.