Introduction

Investment casting, also known as lost-wax casting, is a manufacturing process that has gained prominence in producing custom medical implants. The method’s ability to produce high-precision components with intricate geometries makes it ideal for creating personalized implants that meet the unique anatomical requirements of individual patients. This analysis explores the role of investment casting in the medical field, focusing on its benefits in the creation of custom implants.

Benefits of Investment Casting for Medical Implants

- High Precision and Accuracy:

- Investment casting can produce components with tight tolerances and fine details, crucial for medical implants that must fit precisely within the human body.

- Complex Geometries:

- The process allows for the creation of complex shapes and intricate internal structures that are often required for medical implants, such as orthopedic and dental implants.

- Material Versatility:

- Investment casting supports a wide range of biocompatible materials, including titanium, stainless steel, and cobalt-chromium alloys, which are commonly used in medical implants.

- Surface Finish:

- The smooth surface finish achieved through investment casting reduces the need for extensive post-processing and enhances the biocompatibility of the implants.

- Customization and Personalization:

- The method facilitates the production of patient-specific implants based on individual anatomical data, leading to better fit, comfort, and functionality.

The Process of Creating Custom Medical Implants

- Data Acquisition:

- The process begins with obtaining detailed anatomical data of the patient using imaging techniques such as CT scans or MRI.

- This data is used to create a 3D digital model of the implant.

- Design and Simulation:

- The 3D model is designed and optimized using CAD software.

- Simulations may be conducted to ensure the design meets mechanical and biological requirements.

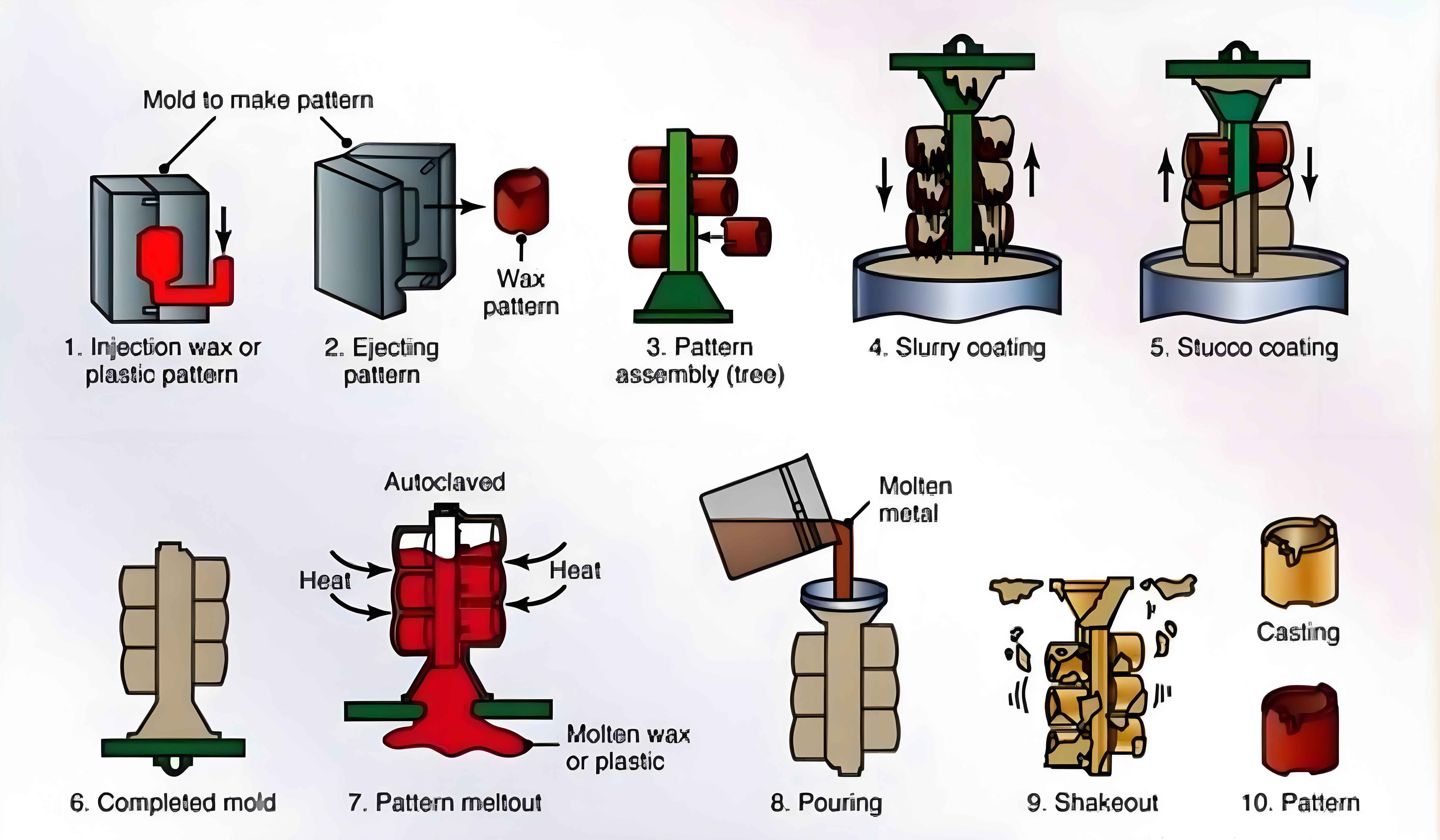

- Pattern Creation:

- A wax or polymer pattern of the implant is created using 3D printing or traditional pattern-making techniques.

- The pattern is an exact replica of the final implant.

- Mold Making:

- The wax pattern is coated with a ceramic slurry to create a ceramic shell or mold.

- The mold is built up in layers to achieve the necessary strength.

- Wax Removal and Casting:

- The ceramic mold is heated to remove the wax, leaving a cavity in the shape of the implant.

- Molten metal is poured into the mold to cast the implant.

- Finishing and Inspection:

- After cooling, the ceramic mold is broken away, and the cast implant is cleaned.

- The implant undergoes finishing processes such as machining and polishing.

- Rigorous inspection and testing ensure the implant meets medical standards.

Applications of Custom Medical Implants

- Orthopedic Implants:

- Custom hip and knee replacements, spinal implants, and bone plates tailored to individual patient anatomy.

- Dental Implants:

- Patient-specific dental implants and abutments for improved fit and comfort.

- Craniofacial Implants:

- Implants used in reconstructive surgery to restore facial structure and function after trauma or disease.

- Cardiovascular Implants:

- Custom heart valves and stents designed to match the patient’s vascular structure.

- Hearing Implants:

- Customized cochlear implants and hearing aids for better auditory outcomes.

Advantages Over Traditional Manufacturing Methods

- Reduced Surgical Time:

- Custom implants fit more accurately, reducing the time required for surgical adjustments during implantation.

- Improved Patient Outcomes:

- Better fit and function of custom implants lead to faster recovery times and improved overall patient satisfaction.

- Enhanced Biocompatibility:

- Investment casting allows for the use of high-quality, biocompatible materials, reducing the risk of rejection and complications.

- Scalability and Efficiency:

- The process is efficient for both single, highly customized implants and small batch production, making it cost-effective for personalized medical solutions.

Conclusion

Investment casting plays a crucial role in the production of custom medical implants, offering unparalleled precision, customization, and material versatility. By leveraging advanced imaging and digital design technologies, this method enables the creation of implants that are tailored to the specific needs of individual patients, leading to better clinical outcomes and enhanced quality of life. As medical technology continues to advance, the role of investment casting in the field of personalized medicine is expected to grow, driving further innovations in patient care.