Spheroidal graphite iron (SG iron), also known as ductile iron, is a type of cast iron known for its unique microstructure, which significantly influences its mechanical properties. The microstructure of spheroidal graphite iron is characterized by spherical graphite nodules dispersed in a matrix of ferrite, pearlite, or a combination of both. This article delves into the microstructural analysis of spheroidal graphite iron and its implications for mechanical performance.

Introduction

The mechanical performance of spheroidal graphite iron is largely determined by its microstructure. Understanding the relationship between microstructure and mechanical properties is crucial for optimizing the performance of spheroidal graphite iron components in various applications, particularly in the automotive and heavy machinery industries.

Microstructure of Spheroidal Graphite Iron

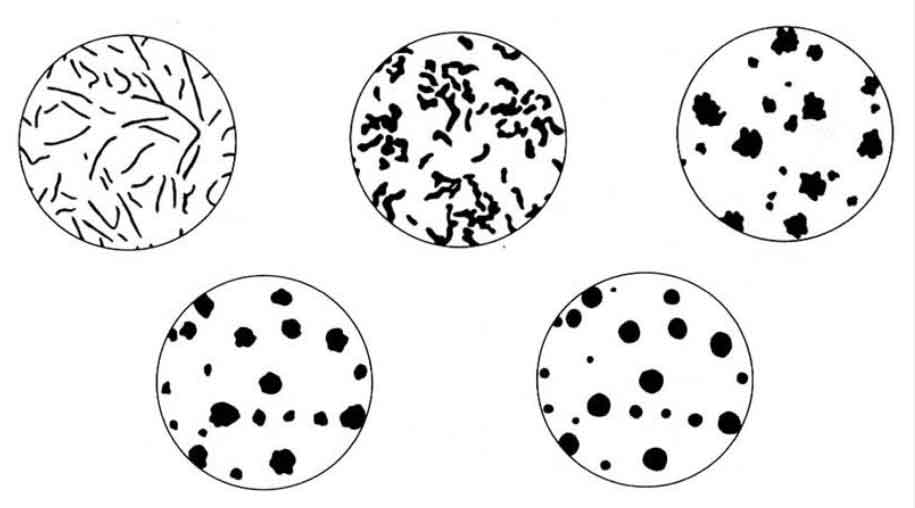

The microstructure of spheroidal graphite iron comprises graphite nodules embedded in a metallic matrix. The shape, size, and distribution of these nodules, as well as the matrix composition, play a critical role in determining the mechanical properties of the material.

Graphite Nodules

Graphite nodules are formed during the solidification process when magnesium or cerium is added to the molten iron. These elements promote the formation of spherical graphite nodules instead of the flake-like graphite found in gray cast iron. The nodules act as crack-arresters, enhancing the ductility and toughness of spheroidal graphite iron.

Metallic Matrix

The metallic matrix of spheroidal graphite iron can be ferritic, pearlitic, or a combination of both. The matrix composition affects the strength, hardness, and wear resistance of the material.

- Ferritic Matrix: Consists of pure iron with small amounts of carbon and other elements. It provides good ductility and impact resistance but lower strength and hardness.

- Pearlitic Matrix: Composed of alternating layers of ferrite and cementite. It offers higher strength and hardness but reduced ductility compared to a ferritic matrix.

- Mixed Matrix: Contains both ferritic and pearlitic regions, providing a balance between strength, hardness, and ductility.

Table 1: Characteristics of Different Matrix Structures in Spheroidal Graphite Iron

| Matrix Type | Composition | Key Properties |

|---|---|---|

| Ferritic | Pure iron with minor elements | High ductility, good impact resistance, lower strength and hardness |

| Pearlitic | Alternating ferrite and cementite | High strength, high hardness, reduced ductility |

| Mixed | Combination of ferritic and pearlitic | Balanced properties of strength, hardness, and ductility |

Implications for Mechanical Performance

Tensile Strength

The tensile strength of spheroidal graphite iron is influenced by both the graphite nodules and the matrix structure. A pearlitic matrix generally provides higher tensile strength compared to a ferritic matrix due to the presence of hard cementite layers.

Table 2: Typical Tensile Strength of Spheroidal Graphite Iron with Different Matrix Structures

| Matrix Type | Tensile Strength (MPa) |

|---|---|

| Ferritic | 400 – 600 |

| Pearlitic | 600 – 900 |

| Mixed | 500 – 750 |

Ductility

Ductility is the ability of a material to deform plastically without fracturing. spheroidal graphite iron with a ferritic matrix exhibits higher ductility due to the absence of brittle cementite phases. The presence of spherical graphite nodules also enhances ductility by preventing crack propagation.

Table 3: Typical Elongation of Spheroidal Graphite Iron with Different Matrix Structures

| Matrix Type | Elongation (%) |

|---|---|

| Ferritic | 15 – 25 |

| Pearlitic | 5 – 10 |

| Mixed | 10 – 15 |

Impact Resistance

Impact resistance is crucial for applications where the material is subjected to sudden or repeated loading. spheroidal graphite iron with a ferritic matrix offers superior impact resistance due to its ability to absorb and dissipate energy.

Wear Resistance

Wear resistance is a measure of a material’s ability to withstand surface degradation due to friction and mechanical interaction. A pearlitic matrix, with its hard cementite phases, provides higher wear resistance compared to a ferritic matrix.

Microstructural Analysis Techniques

Optical Microscopy

Optical microscopy is used to examine the size, shape, and distribution of graphite nodules and the matrix structure. It provides valuable information on the overall microstructure and any defects present.

Scanning Electron Microscopy (SEM)

SEM offers higher magnification and resolution than optical microscopy, allowing for detailed analysis of the microstructure. It is particularly useful for observing the morphology of graphite nodules and the matrix phases.

X-ray Diffraction (XRD)

XRD is used to identify the crystalline phases present in the spheroidal graphite iron matrix. It provides insights into the proportions of ferrite, pearlite, and other phases, which correlate with the mechanical properties.

Energy Dispersive X-ray Spectroscopy (EDS)

EDS, often used in conjunction with SEM, provides elemental composition analysis. It helps in identifying the distribution of alloying elements within the microstructure.

Case Study: Microstructural Optimization for Automotive Components

A study on optimizing the microstructure of spheroidal graphite iron for automotive components revealed that a mixed matrix structure offers the best balance of properties for applications such as crankshafts and suspension parts. By controlling the cooling rate and heat treatment processes, manufacturers can achieve a desired microstructure that enhances performance and longevity.

Table 4: Performance Comparison of Spheroidal Graphite Iron with Different Matrix Structures in Automotive Components

| Component | Matrix Type | Performance Characteristics |

|---|---|---|

| Crankshafts | Mixed | High strength, good ductility, wear resistance |

| Suspension Parts | Ferritic | High ductility, excellent impact resistance |

| Gears | Pearlitic | High strength, high wear resistance |

Conclusion

The microstructural analysis of spheroidal graphite iron is essential for understanding its mechanical performance and optimizing its properties for various applications. The balance between graphite nodules and matrix composition plays a critical role in determining the tensile strength, ductility, impact resistance, and wear resistance of spheroidal graphite iron. By leveraging advanced microstructural analysis techniques, manufacturers can tailor the properties of spheroidal graphite iron to meet the specific demands of different applications, particularly in the automotive and heavy machinery industries.