Spheroidal graphite iron is widely used in various industries due to its excellent mechanical properties and good corrosion resistance. However, its performance in aggressive environments, such as marine, acidic, and alkaline conditions, is of particular interest. This article explores the corrosion resistance of spheroidal graphite iron in such environments, the factors influencing its performance, and potential strategies to enhance its durability.

Introduction

Corrosion is a natural process that can significantly affect the longevity and reliability of materials used in harsh environments. For spheroidal graphite iron, understanding the factors that contribute to its corrosion resistance is crucial for improving its performance in applications such as pipelines, automotive components, and marine structures.

Factors Influencing Corrosion Resistance

The corrosion resistance of spheroidal graphite iron is influenced by several factors, including its microstructure, alloying elements, and the environmental conditions it is exposed to.

Microstructure

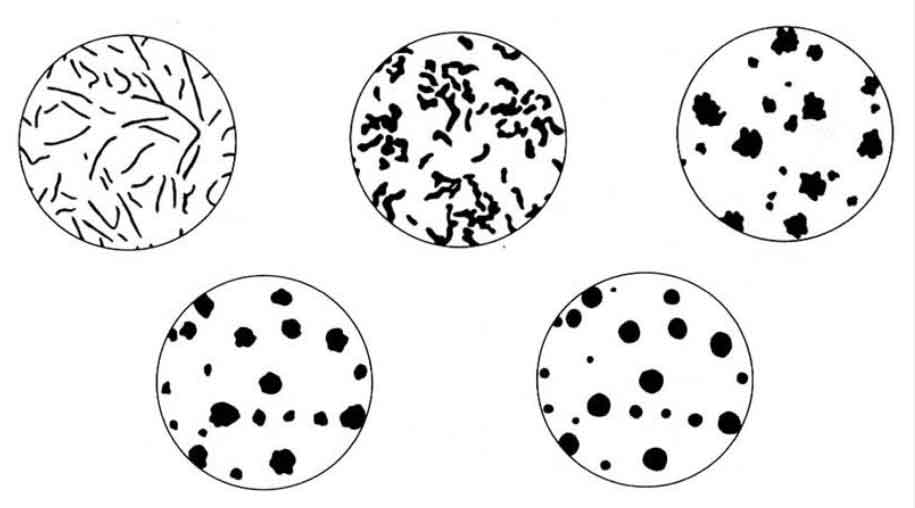

The microstructure of spheroidal graphite iron, characterized by spherical graphite nodules dispersed in a metallic matrix, plays a significant role in its corrosion behavior. The distribution and size of graphite nodules, along with the matrix composition, determine the material’s susceptibility to corrosion.

Alloying Elements

The presence of alloying elements such as silicon, copper, nickel, and chromium can enhance the corrosion resistance of spheroidal graphite iron. These elements form protective oxide layers on the surface, which act as barriers against corrosive agents.

Environmental Conditions

The type and concentration of corrosive agents, temperature, and pH levels of the environment also impact the corrosion resistance of spheroidal graphite iron. Aggressive environments, such as those containing chlorides, sulfates, and acids, pose greater challenges.

Corrosion Behavior in Different Environments

Marine Environments

Marine environments are highly corrosive due to the presence of salts, particularly chlorides, which accelerate the corrosion process. spheroidal graphite iron exposed to marine conditions often forms rust (iron oxide), which can compromise its structural integrity.

Table 1: Corrosion Rate of Spheroidal Graphite Iron in Marine Environment

| Time (months) | Corrosion Rate (mm/year) |

|---|---|

| 1 | 0.12 |

| 6 | 0.15 |

| 12 | 0.18 |

| 24 | 0.22 |

Acidic Environments

Acidic environments, such as those found in chemical processing industries, can cause severe corrosion in spheroidal graphite iron. Acids like sulfuric acid and hydrochloric acid are particularly aggressive, leading to rapid material degradation.

Table 2: Corrosion Rate of Spheroidal Graphite Iron in Acidic Environment (1M HCl)

| Time (hours) | Corrosion Rate (mm/year) |

|---|---|

| 1 | 1.0 |

| 5 | 1.3 |

| 10 | 1.6 |

| 24 | 2.0 |

Alkaline Environments

Alkaline environments are generally less corrosive to spheroidal graphite iron compared to acidic environments. However, the presence of hydroxides can still lead to the formation of rust and pitting over time.

Table 3: Corrosion Rate of Spheroidal Graphite Iron in Alkaline Environment (1M NaOH)

| Time (days) | Corrosion Rate (mm/year) |

|---|---|

| 1 | 0.05 |

| 5 | 0.07 |

| 10 | 0.09 |

| 20 | 0.12 |

Enhancing Corrosion Resistance

Alloying Additions

Adding alloying elements such as silicon, copper, nickel, and chromium can significantly enhance the corrosion resistance of spheroidal graphite iron. These elements form stable oxide layers on the surface, which protect the underlying material from corrosive agents.

Table 4: Effect of Alloying Elements on Corrosion Resistance

| Alloying Element | Typical Addition (%) | Corrosion Resistance Improvement |

|---|---|---|

| Silicon | 2.0 – 3.0 | Forms protective silica layer |

| Copper | 0.5 – 1.5 | Enhances resistance to chlorides |

| Nickel | 0.5 – 2.0 | Improves resistance in acidic environments |

| Chromium | 0.1 – 0.5 | Forms protective chromia layer |

Protective Coatings

Applying protective coatings, such as epoxy, polyurethane, or galvanization, can provide an additional barrier against corrosive agents. These coatings are particularly effective in marine and acidic environments.

Cathodic Protection

Cathodic protection involves using sacrificial anodes or impressed current systems to protect spheroidal graphite iron structures from corrosion. This method is widely used in pipelines, marine structures, and underground storage tanks.

Case Study: Spheroidal Graphite Iron Pipes in Water Distribution Systems

A case study on the use of spheroidal graphite iron pipes in water distribution systems demonstrates the importance of corrosion resistance. In environments with high chloride content, pipes alloyed with copper and coated with epoxy showed significantly lower corrosion rates compared to unalloyed, uncoated pipes.

Table 5: Performance Comparison of Spheroidal Graphite Iron Pipes in Water Distribution Systems

| Pipe Type | Corrosion Rate (mm/year) | Service Life (years) |

|---|---|---|

| Unalloyed, uncoated | 0.25 | 20 |

| Alloyed with Cu, coated with epoxy | 0.05 | 50 |

Conclusion

The corrosion resistance of spheroidal graphite iron is a critical factor in determining its suitability for use in aggressive environments. By understanding the effects of microstructure, alloying elements, and environmental conditions, it is possible to enhance the durability and performance of spheroidal graphite iron. The use of protective coatings, alloying additions, and cathodic protection are effective strategies for mitigating corrosion and extending the service life of spheroidal graphite iron components.