Lost wax casting is precise and versatile manufacturing process used to create complex metal components. Despite its advantages, the process can be susceptible to various casting defects. These defects can significantly impact the quality and performance of the final product. This article explores common casting defects in lost wax casting and provides strategies for reducing these defects to improve overall casting quality.

Introduction to Lost Wax Casting

Lost wax casting involves creating a wax model of the desired part, coating it with a ceramic shell, and then melting out the wax to leave a mold cavity. Molten metal is poured into the cavity, and once the metal solidifies, the ceramic shell is removed to reveal the metal casting. This process is ideal for producing components with intricate geometries and fine details.

Key Steps in Lost Wax Casting

- Pattern Creation: Making a wax model using injection molding or manual carving.

- Assembly: Attaching multiple wax models to a central wax sprue to form a tree-like structure.

- Shell Building: Dipping the wax assembly into a ceramic slurry and coating it with sand to build a strong ceramic shell.

- Dewaxing: Heating the ceramic shell to remove the wax, leaving a hollow cavity.

- Metal Pouring: Pouring molten metal into the ceramic mold.

- Shell Removal: Breaking away the ceramic shell to reveal the metal casting.

- Finishing: Cleaning and removing any excess material from lost wax casting.

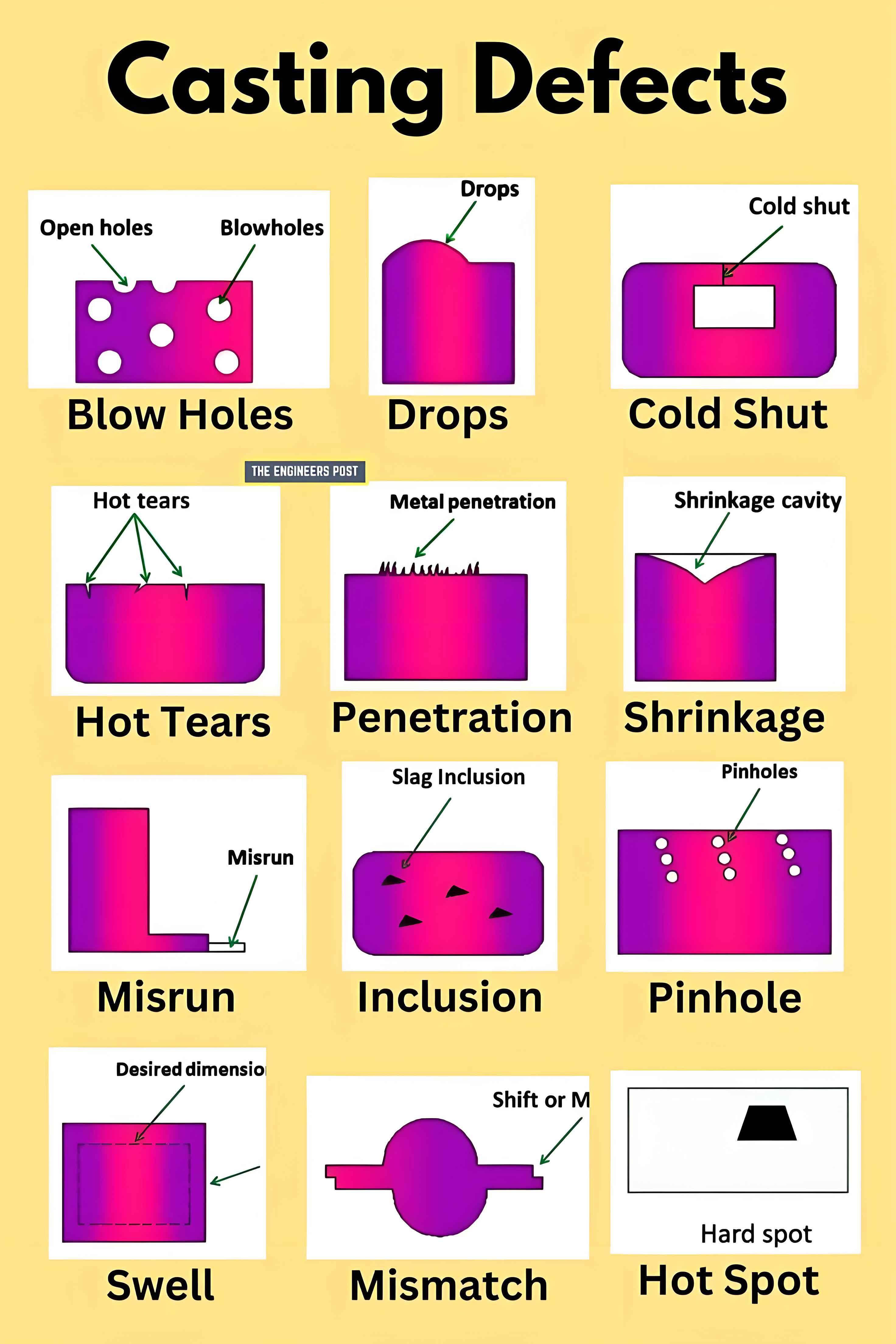

Common Casting Defects in Lost Wax Casting

1. Porosity

Porosity occurs when gas bubbles become trapped in the metal during solidification, resulting in small holes or voids within lost wax casting. This defect can weaken the casting and reduce its structural integrity.

2. Shrinkage

Shrinkage defects occur when the metal contracts during cooling and solidification, leading to internal voids or cracks. These defects are often found in areas where the metal solidifies last.

3. Inclusions

Inclusions are foreign materials, such as sand, slag, or oxides, that become entrapped within the metal during pouring. Inclusions can compromise the mechanical properties of lost wax casting.

4. Misruns

Misruns occur when the molten metal does not completely fill the mold cavity, resulting in incomplete or missing sections of lost wax casting. This defect is often caused by insufficient pouring temperature or poor mold design.

5. Cold Shuts

Cold shuts are formed when two streams of molten metal meet but do not fuse together properly, creating a weak seam or line. This defect is typically caused by low pouring temperature or poor gating system design.

Strategies for Reducing Casting Defects

To reduce casting defects in lost wax casting, it is important to focus on optimizing each step of the process. Here are some key strategies:

1. Improving Wax Pattern Quality

Techniques:

- High-Quality Wax: Using high-quality wax materials to create smooth and precise patterns.

- Proper Storage: Storing wax patterns in controlled environments to prevent deformation.

- Inspection: Inspecting wax patterns for defects before assembly.

Benefits:

- Reduced risk of pattern defects transferring to the final casting.

- Improved dimensional accuracy and surface finish.

2. Optimizing Ceramic Shell Building

Techniques:

- Controlled Slurry: Using a well-controlled ceramic slurry composition to build strong and uniform shells.

- Proper Drying: Ensuring proper drying conditions to avoid cracks and inconsistencies in the shell.

- Reinforcement: Reinforcing critical areas of the shell to withstand the thermal and mechanical stresses during pouring.

Benefits:

- Reduced risk of shell cracking and failure.

- Improved mold stability and accuracy.

3. Enhancing Dewaxing Process

Techniques:

- Autoclave Dewaxing: Using autoclaves to efficiently remove wax without damaging the ceramic shell.

- Proper Heating: Ensuring uniform and controlled heating to prevent shell damage.

- Wax Recovery: Implementing wax recovery systems to reuse wax and reduce waste.

Benefits:

- Reduced risk of shell damage during dewaxing.

- Improved mold integrity and reduced waste.

4. Optimizing Metal Pouring

Techniques:

- Controlled Pouring Temperature: Maintaining the optimal pouring temperature to ensure complete mold filling.

- Proper Gating System: Designing an efficient gating system to ensure smooth and continuous metal flow.

- Vacuum Casting: Using vacuum casting techniques to minimize gas entrapment and reduce porosity.

Benefits:

- Reduced risk of misruns, cold shuts, and porosity.

- Improved casting quality and consistency.

5. Efficient Finishing Processes

Techniques:

- Inspection: Thoroughly inspecting castings for defects before finishing.

- Automated Finishing: Using automated grinding, polishing, and cleaning systems to improve consistency and reduce labor costs.

- Surface Treatments: Implementing surface treatments such as shot blasting and chemical finishing to enhance surface quality.

Benefits:

- Reduced risk of surface defects and improved surface finish.

- Enhanced overall casting quality.

Tables and Lists for Key Processes and Techniques

Table 1: Common Casting Defects in Lost Wax Casting

| Defect | Description | Causes |

|---|---|---|

| Porosity | Gas bubbles trapped in metal creating voids | Insufficient degassing, high pour temp |

| Shrinkage | Internal voids or cracks due to metal contraction | Inadequate feeding, poor mold design |

| Inclusions | Foreign materials entrapped in the metal | Contaminated melt, improper pouring |

| Misruns | Incomplete filling of mold cavity | Low pour temp, poor gating system |

| Cold Shuts | Weak seams from improperly fused metal streams | Low pour temp, poor gating system |

Table 2: Strategies for Reducing Casting Defects

| Strategy | Techniques | Benefits |

|---|---|---|

| Improving Wax Pattern Quality | High-quality wax, proper storage, inspection | Reduced pattern defects, improved accuracy |

| Optimizing Ceramic Shell Building | Controlled slurry, proper drying, reinforcement | Reduced shell cracking, improved mold stability |

| Enhancing Dewaxing Process | Autoclave dewaxing, proper heating, wax recovery | Reduced shell damage, improved mold integrity |

| Optimizing Metal Pouring | Controlled pour temp, proper gating system, vacuum casting | Reduced misruns, cold shuts, porosity |

| Efficient Finishing Processes | Inspection, automated finishing, surface treatments | Reduced surface defects, improved finish quality |

List: Key Benefits of Reducing Casting Defects

- Improved Mechanical Properties: Enhanced strength, durability, and reliability of castings.

- Increased Yield: Higher production yield due to fewer defective castings.

- Cost Savings: Reduced scrap and rework costs, leading to overall cost savings.

- Enhanced Surface Finish: Improved surface quality and appearance of the final product.

- Consistency: Greater consistency in lost wax casting quality and performance.

Case Studies: Successful Implementation of Defect Reduction Strategies

Case Study 1: Automotive Industry

An automotive manufacturer implemented high-quality wax materials and automated wax injection systems to produce precise and consistent patterns for engine components. By optimizing the wax pattern quality and reinforcing critical areas of the ceramic shell, they significantly reduced the occurrence of pattern and shell-related defects. The improved process control resulted in higher yield and better overall casting quality.

Case Study 2: Aerospace Sector

A leading aerospace company adopted vacuum casting and advanced gating system designs to produce turbine blades with reduced porosity and cold shuts. By maintaining precise pouring temperatures and using vacuum technology, they minimized gas entrapment and ensured complete mold filling. The result was a significant reduction in porosity and improved mechanical properties of lost wax castings.

Case Study 3: Medical Device Manufacturing

A medical device manufacturer utilized autoclave dewaxing and controlled slurry composition to produce orthopedic implants. The use of autoclave dewaxing ensured efficient wax removal without damaging the ceramic shell, while the controlled slurry composition provided consistent shell strength and quality. These improvements led to a reduction in shell-related defects and enhanced the overall quality of the implants.

Conclusion

Reducing casting defects in lost wax casting requires a comprehensive approach that involves optimizing each step of the process. By focusing on improving wax pattern quality, optimizing ceramic shell building, enhancing the dewaxing process, and optimizing metal pouring and finishing processes, manufacturers can significantly reduce the occurrence of casting defects. The implementation of these strategies leads to improved casting quality, increased yield, and overall cost savings. As advancements in technology and process control continue, the potential for further reducing defects and enhancing the quality of lost wax casting will only grow, ensuring that this versatile manufacturing method remains a key player in producing high-precision and high-performance metal components.