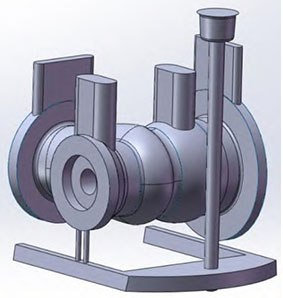

The seawater pipeline system of a ship is the only channel for seawater to enter the ship. Whether it is the cooling system of the engine, maintenance and cleaning of the hull, or the inlet and outlet control of deep-sea operations, all seawater needed for smooth navigation of the ship comes from the seawater pipeline system of the ship. As an important component of marine seawater pipeline systems, three-way valves play a crucial role in ensuring the smooth operation of ships due to their excellent service performance. The three-way valve plays a crucial role in the seawater pipeline system of ships. The structure of a three-way valve is complex and the service environment is harsh. It is mostly made of cast brass and cast bronze, and the three-way valve is prepared in one molding by casting methods. Therefore, the casting quality of three-way valves directly affects their service performance and service life. Common casting defects include porosity, sand holes, shrinkage cavities, shrinkage porosity, slag inclusion, and insufficient pouring. The formation of porosity, shrinkage porosity, and shrinkage cavities is related to the casting structure and pouring process, while other defects are mostly caused by improper operation or failure to follow the design process during the actual pouring process. Reasonable design of pouring system and casting process parameters is an effective way to reduce defects.

Numerical simulation research plays an increasingly important role in practical production. It can calculate the flow and temperature distribution of metal liquid at different times and positions through numerical simulation methods, thereby simulating the filling and solidification processes, predicting possible defects, guiding the design of pouring systems and the determination of casting process parameters, shortening the development cycle, and greatly reducing the design cost of casting processes. The difference in casting quality between two casting systems was compared, and it was found that the effects of casting temperature, mold temperature, and filling time on shrinkage and porosity were gradually reduced. Through the optimal casting system, the defects were ultimately basically eliminated. By redesigning the filling process of the pouring system, the problems of shrinkage porosity and dimensional deformation of castings have been reduced. The casting system was optimized based on the defects of the initial casting system, and the process parameters were optimized through orthogonal experiments. The castings cast according to the optimal parameters had no defects. The influence of different alloy compositions on the casting quality of wind turbine rotor hub was compared. The study showed that changes in alloy composition can cause different defects in the casting process. Through comparative analysis, a more suitable alloy composition for the current casting design was obtained. In addition, in addition to conventional casting, numerical simulation can also provide production guidance for special casting and reduce trial and error costs. An analysis was conducted on the die-casting process of aluminum alloy, and simulations were conducted on rapid prototyping and investment casting. Based on the optimized results obtained from numerical simulations, castings were successfully prepared, greatly accelerating the design process. In summary, using numerical simulation to guide the design of pouring systems and the determination of casting process parameters is a reliable casting design approach with high production significance.

Due to the service environment of the three-way valve being high-speed flowing seawater medium, it is required that the material of the three-way valve must be corrosion-resistant. Otherwise, in continuous operation for several months, the three-way valve is prone to failure due to corrosion, affecting the normal operation of the entire ship pipeline system. The common materials for three-way valves are cast brass and cast bronze. Aluminum bronze has high strength, conductivity, thermal conductivity, and wear resistance, and can be used as a structural material in engineering. Its reliable corrosion resistance not only resists the corrosion of atmospheric environment, high temperature, low temperature, and harsh chemical environment, but also has certain biological stability, which is conducive to its service in complex environments. In addition, aluminum bronze has a large volume shrinkage, showing obvious layer by layer solidification characteristics, good casting performance, and is easy to prepare castings with dense structure, but it is prone to shrinkage porosity.

The numerical simulation process of the casting process involves dividing the model into finite elements using the finite element method, and calculating the state of the model at different time points based on fluid flow and heat dissipation equations. After visualization processing, the calculation results are displayed in the form of temperature field and solid phase percentage. By analyzing the temperature differences and solidification sequence during the metal liquid casting process, the possible defects such as hot spots, shrinkage porosity, and shrinkage holes in the pouring system can be analyzed.

(1) Based on the geometric shape and structural characteristics of the three-way valve castings, two types of pouring systems, bottom pouring and bottom pouring rain pouring, were designed. The results showed that the bottom pouring rain pouring system corresponded to better quality of the castings. After adjusting the distribution of the bottom pouring rain shower type internal runner, it was found that concentrating the internal runner in the thin-walled area resulted in a more favorable temperature distribution for sequential solidification of the casting, thereby reducing casting defects and improving casting quality.

(2) By combining orthogonal experiments and numerical simulations, it was found that the effects of three pouring parameters, namely pouring temperature, pouring speed, and sand mold preheating temperature, on the porosity of castings decreased in sequence. The optimal combination of pouring parameters was pouring temperature of 1100 ℃, pouring speed of 4.5 kg/s, and sand mold preheating temperature of 150 ℃.