Introduction

The integrated exhaust technology of cylinder head is a major breakthrough in cylinder head casting technology, and the integrated casting of cylinder head and exhaust manifold has become the mainstream energy-saving and emission reduction preferred technology in recent years. In traditional engine design, the cylinder head and exhaust manifold are designed separately. The development of the exhaust manifold requires a large investment, the manufacturing cost is high, and the casting process is limited Due to the requirements of exhaust duct flow field and thermal stress, the scrap rate is also high, resulting in difficulties such as high overall cost, large space size, and long product development cycle. With the increase of emission requirements, this technology has become a standard technology for China VI emissions. It has excellent effects on reducing engine cold start emissions, not only achieving comprehensive energy-saving and emission reduction effects, but also further reducing engine costs. Although cylinder head integrated exhaust technology has many advantages, its casting difficulty is also incomparable to traditional cylinder heads. The well connected water channel structure puts higher requirements on the casting process, especially low-pressure casting. The main molding methods for cylinder heads include gravity casting, low-pressure casting, etc. Among them, low-pressure casting is widely used due to its high automation rate and high material utilization rate. However, in actual production, many casting defects such as cold shut, cracks, insufficient pouring, shrinkage, porosity, oxide inclusions, etc. may occur on the surface and inside of castings. This article analyzes the causes of cold shut defects in the typical low-pressure casting IEM cylinder head forming process, and proposes preventive and control measures to improve the product qualification rate and achieve good economic benefits.

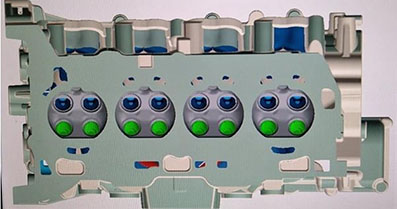

The engine cylinder head is a small cylinder head produced using low-pressure metal casting technology, with similar materials AC4B aluminum alloy, with a total casting weight of approximately 16Kg and dimensions of approximately 458 * 288 * 142. The waterway, airway, and oil chamber are all formed by sand cores made of resin sand. The product adopts the bottom injection low-pressure casting process, forming metal molds with upper and lower, left and right, front and rear parting. The casting pressure, temperature, time, cooling, etc. are all automatically controlled by the pouring machine. After the casting is completed, the appearance quality is manually inspected. The waterway sand core adopts hot core box technology Art forming, core shooting temperature, pressure, time, and sintering time are automatically controlled by the core making machine. After sintering, the sintering thickness and sand core appearance are manually inspected. Cold shut is mainly a defect formed during the filling and solidification process of castings due to poor fluidity of aluminum liquid and unreasonable mold temperature, which hinders the flow of aluminum liquid in the mold cavity. The main manifestation of this defect is the incomplete surface or contour of the cylinder head defect, which affects the overall strength, machining quality, and product performance of the casting to a certain extent, resulting in product scrap. Faced with the existing problems, the project team has identified two improvement directions based on the mechanism of cold insulation: 1) improving the fluidity of aluminum liquid; 2) Improve the rationality of temperature field distribution in molds; At the same time, the project team brainstormed and further analyzed the cold insulation defects, suspecting that factors affecting the cold insulation defects on the outer wall of the small end sensor may include mold differences, equipment differences, manual time, filling pressure time, cooling time flow rate, and aluminum liquid temperature Degree, paint detachment status, mold exhaust groove, small end structure.

conclusion

1) When designing products, full consideration should be given to avoiding possible problems during casting filling and solidification processes. In the process structure design, the exhaust groove, reinforcement ribs and other process structures should be reasonably designed by combining previous projects and CAE analysis methods. At the same time, corresponding problem avoidance tables should be formed to provide experience accumulation for subsequent models.

2) In the process of problem analysis and solution, Six Sigma and other analytical tools can be fully utilized to systematically analyze and verify the causes and problems, which is conducive to quickly discovering and systematically solving problems, and avoiding the recurrence of problems caused by inadequate analysis.