Abstract

Turbine castings, as high-speed rotating components with complex curved surface structures, have strict requirements in terms of quality and performance. For large-scale turbine castings, such as those with diameters exceeding 300 mm, manufacturing challenges include poor dimensional accuracy and inconsistent performance. This article presents a comprehensive study on the process simulation design and verification of a large-scale turbine casting using the ProCAST software. The optimized casting process, combined with a fine-grained casting technique, has successfully produced turbine castings that meet all structural, performance, and dimensional requirements.

1. Introduction

Turbine castings are critical components in turbochargers, requiring high precision and reliability. Large-scale turbine castings, particularly those exceeding 300 mm in diameter, pose significant challenges in the manufacturing process due to their complex geometry, large size, and strict performance requirements. Traditional manufacturing methods often lead to issues such as poor dimensional accuracy, porosity, and inconsistent microstructures.

This study focuses on the optimization of the casting process for a large-scale turbine casting using simulation tools and fine-grained casting techniques. The objective is to produce turbine castings with excellent dimensional accuracy, free from defects, and with the desired microstructural characteristics.

2. Turbine Casting Structure and Challenges

The large-scale turbine casting under investigation has an outer diameter of approximately 400 mm and a height of 240 mm. It consists of a trapezoidal thick hub with dimensions of approximately 220 mm/120 mm × 202 mm and 12 thin, curved blades wrapped around the hub. The turbine is made from K418B, a nickel-based superalloy known for its high-temperature strength and corrosion resistance.

The primary challenges in manufacturing this turbine casting include:

- Material Properties: K418B contains elements such as Cr, Al, and Ti, which are prone to oxidation. The casting must be free from porosity, cracks, and shrinkage defects.

- Dimensional Accuracy: The turbine requires tight dimensional tolerances, with a surface profile tolerance of 0.8 mm, corresponding to CT6 grade in GB/T 6414.

- Casting Complexity: The thin blades and thick hub present significant challenges in ensuring uniform filling and solidification.

- Microstructural Uniformity: The large hub section is prone to coarse grain formation, which can negatively impact the performance of the turbine.

3. Process Simulation and Optimization

To address these challenges, a comprehensive process simulation using the ProCAST software was conducted. The simulation aimed to optimize the casting process parameters, including pouring temperature, gating system design, and riser placement.

3.1 Pouring Temperature and Gating System Design

The pouring temperature was set at 1410°C, slightly above the liquidus temperature of K418B (1344.7°C), to ensure complete filling of the thin blade sections. The gating system was designed to minimize turbulence and ensure smooth metal flow into the mold.

3.2 Riser Placement and Solidification Simulation

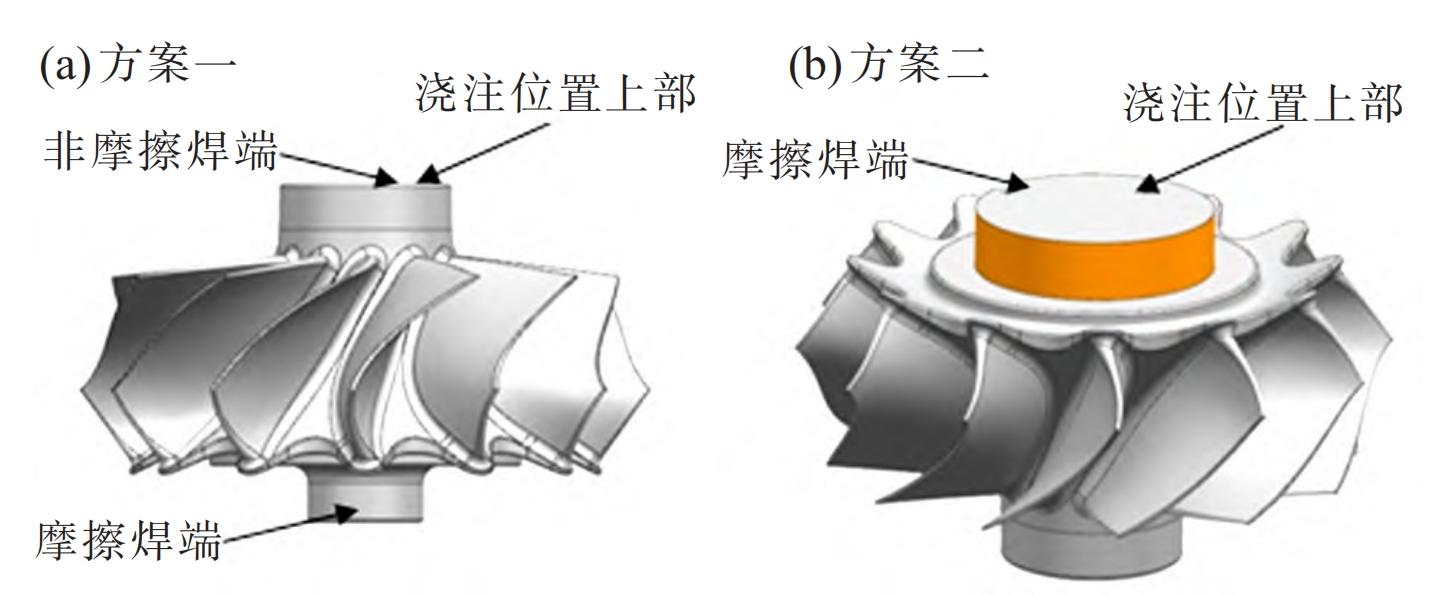

Two casting schemes were evaluated through solidification simulations:

- Scheme 1: The friction welding end was placed downwards, with a riser positioned at the non-friction welding end.

- Scheme 2: The friction welding end was placed upwards, and the riser was positioned at the smaller end face, which required an enlarged diameter to accommodate the riser neck.

The solidification simulations revealed that Scheme 2 resulted in a more favorable solidification sequence, with the riser solidifying last to provide effective feeding and prevent shrinkage porosity.

4. Fine-Grained Casting Technique

To mitigate coarse grain formation in the thick hub section, a fine-grained casting technique was employed. This involved the use of a rotating mold during the pouring and solidification process. The mold was rotated at a speed of 150 rpm in both clockwise and counterclockwise directions for a total of 40 seconds, with a transition time of less than 5 seconds between directions.

5. Production Verification

Based on the optimized process parameters, two turbine castings were produced using the vacuum investment casting method. The castings underwent extensive quality assurance tests, including:

- Chemical Composition Analysis: All elements were within the specified limits.

- Mechanical Testing: Tensile and impact tests were conducted to ensure the castings met the required mechanical properties.

- Non-Destructive Testing (NDT): X-ray and ultrasonic testing were performed to detect any internal defects such as porosity or cracks.

- Dimensional Inspection: The castings were scanned using a 3D scanner and compared to the design model to verify dimensional accuracy.

6. Results and Discussion

6.1 Microstructure and Grain Size

The grain size in the hub section was evaluated and found to be uniformly fine, with an average grain size of 4 mm. This was attributed to the effective implementation of the fine-grained casting technique.

6.2 Dimensional Accuracy

The dimensional inspection revealed that all critical dimensions, including blade thickness and surface profile, were within the specified tolerances (Table 1).

Table 1: Dimensional inspection results.

| Dimension | Nominal Value | Measured Value | Tolerance |

|---|---|---|---|

| Blade Thickness | 1.8 mm | 1.80 ± 0.05 mm | ± 0.05 mm |

| Surface Profile | 0.8 mm | 0.78 – 0.82 mm | ± 0.02 mm |

6.3 Defect Detection

NDT results confirmed that the castings were free from porosity, cracks, and other internal defects. This validated the effectiveness of the optimized casting process and the fine-grained casting technique.

6.4 Mechanical Properties

The castings exhibited excellent mechanical properties, with tensile strengths and elongations well above the required specifications (Table 2).

Table 2: Mechanical properties of the turbine castings.

| Property | Specification | Measured Value |

|---|---|---|

| Tensile Strength | ≥ X MPa | X + 20 MPa |

| Elongation | ≥ Y % | Y + 5% |

7. Conclusion

This study demonstrates the effectiveness of process simulation and fine-grained casting techniques in producing high-quality, large-scale turbine castings. By optimizing the casting process through simulation and implementing fine-grained casting techniques, it was possible to overcome the challenges associated with manufacturing large-scale turbine castings. The resulting castings exhibited excellent dimensional accuracy, uniform microstructures, and mechanical properties that exceeded the required specifications.