Abstract

Cast steel joints have become widely used in critical connections of long-span spatial structures due to their unique properties. This article discusses the application of cast steel joints in bridge engineering, particularly their innovative use in large-scale intersecting nodes of arch-shaped cable towers in a highway landscaped bridge. By employing cast steel joints, the design achieves both aesthetic appeal and avoids residual welding stress issues commonly encountered in traditional welded joints. This approach offers valuable insights for similar engineering projects.

Introduction

In recent years, cast steel joints have gained significant popularity in the construction of long-span spatial structures due to their ability to combine the material-saving and aesthetic advantages of tubular intersections while mitigating the welding residual stress issues commonly associated with traditional welded joints. With advancements in casting technology, cast steel joints now exhibit excellent plasticity, toughness, and weldability, making them ideal for complex structural connections.

Bridge engineering has witnessed a growing trend towards more aesthetically pleasing and structurally intricate designs, often requiring nodes that can withstand complex loading conditions. This article focuses on the application of cast steel joints in a highway landscaped bridge, highlighting their benefits and design considerations.

Properties of Cast Steel Joints

Material Composition

Cast steel is categorized into cast carbon steel and cast low-alloy steel. Due to their inferior quenchability and mechanical properties, cast carbon steel is less commonly used in structural applications. Instead, cast low-alloy steel, which incorporates alloying elements such as manganese (Mn), silicon (Si), and chromium (Cr), is preferred for its enhanced strength, plasticity, toughness, and weldability.

Table 1 presents the chemical composition requirements for two commonly used cast steel grades (GS-16Mn5 and GS-20Mn5) according to the German standard DIN 17182.

| Grade | C (%) | Si (%) | Mn (%) | P (%) | S (%) | Cr (%) | Mo (%) | Ni (%) |

|---|---|---|---|---|---|---|---|---|

| GS-16Mn5 | 0.15 – 0.20 | ≤ 0.60 | 1.00 – 1.50 | ≤ 0.020 | ≤ 0.015 | ≤ 0.3 | ≤ 0.15 | ≤ 0.40 |

| GS-20Mn5 | 0.17 – 0.23 | ≤ 0.60 | 1.00 – 1.50 | ≤ 0.020 | ≤ 0.015 | ≤ 0.3 | ≤ 0.15 | ≤ 0.40 |

Table 2 summarizes the mechanical properties of these grades under various heat treatment conditions and wall thicknesses.

| Grade | Heat Treatment | Wall Thickness (mm) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation (%) | Impact Energy (J) |

|---|---|---|---|---|---|---|

| GS-16Mn5 | Normalized | ≤ 50 | ≥ 260 | 430 – 600 | ≥ 25 | ≥ 65 |

| > 50 ≤ 100 | ≥ 230 | 430 – 600 | ≥ 25 | ≥ 45 | ||

| GS-20Mn5 | Normalized | ≤ 50 | ≥ 300 | 500 – 650 | ≥ 22 | ≥ 55 |

| > 50 ≤ 100 | ≥ 280 | 500 – 650 | ≥ 22 | ≥ 40 | ||

| Quenched & Tempered | ≤ 50 | ≥ 360 | 500 – 650 | ≥ 24 | ≥ 70 |

Types and Characteristics

Cast steel joints are available in various forms, including tree-type, hinged, and hybrid nodes, each with unique advantages.

- Tree-type Cast Steel Joints: Replace traditional tubular intersections with butt welds, distributing welding stress and improving structural integrity.

- Hinged Cast Steel Joints: Simplify connections at member ends, enhancing aesthetic appeal.

- Hybrid Cast Steel Joints: Combine the benefits of tree-type and hinged joints.

Compared to traditional tubular intersections, cast steel joints offer the following advantages:

- Versatility: Can be custom-made to fit complex geometries and internal cavities.

- High Load-bearing Capacity: Semi-solid or hollow design with thicker walls, resulting in higher strength and deformation resistance.

- Reduced Stress Concentration: Eliminates the need for complex welds, thus mitigating stress concentrations.

- Excellent Weldability: Stringent control over C, S, and P content ensures superior material properties.

- Broad Application Range: Suitable for various locations, shapes, and sizes.

Production Process of Cast Steel Joints

The production of cast steel joints involves three primary stages: casting, heat treatment, and post-processing.

Casting Process

The casting process comprises pattern making, molding, smelting, and pouring.

- Pattern Making: Patterns are typically made from wood, with strict control over dimensions, angles, and surface finish.

- Molding: Uses stable surface sand, often coated with a suitable release agent to prevent sand adhesion.

- Smelting: Involves the use of high-quality scrap steel and careful control over the smelting process to ensure material purity.

- Pouring: Steel is poured into the mold at a controlled rate to avoid turbulence and ensure even filling.

Heat Treatment

Heat treatment improves mechanical properties and relieves casting stresses. The process includes normalizing, quenching, and tempering, with temperatures and durations specified by the relevant standards.

Post-processing

Post-processing steps include shakeout, gating system removal, defect repair, grinding, shot blasting, and rust prevention.

Quality Control

Quality control is vital for producing defect-free cast steel joints. Key control points include:

- Pattern Quality: Verified through 3D coordinate measurements and inspection reports.

- Material Composition: Strict adherence to standards such as DIN 17182, with chemical and mechanical property reports.

- Internal Quality: Ensuring no porosity, shrinkage, blowholes, or cracks, with ultrasonic testing as necessary.

Application in Bridge Engineering

Engineering Background

A highway overpass bridge designed as a double-arch, single-pylon, double-cable-plane steel box girder cable-stayed bridge (span arrangement: 46m + 46m; bridge width: 11.8m) features cast steel joints in its complex tower intersections.

Design Considerations

The tower, constructed from steel tubes filled with concrete, intersects at a critical point requiring high structural integrity. Traditional welded tubular intersections would introduce significant stress concentrations and welding residuals. Therefore, cast steel joints were adopted.

- Material Specification: GS-20Mn5 grade cast steel, meeting DIN 17182 standards for chemical composition and mechanical properties.

- Design Details: The cast steel joint, with a wall thickness 2.5 times that of the connecting tubes, incorporates thickened waists, hollowed interiors with cross-sectional bracing, and smooth transitions to facilitate cleaning.

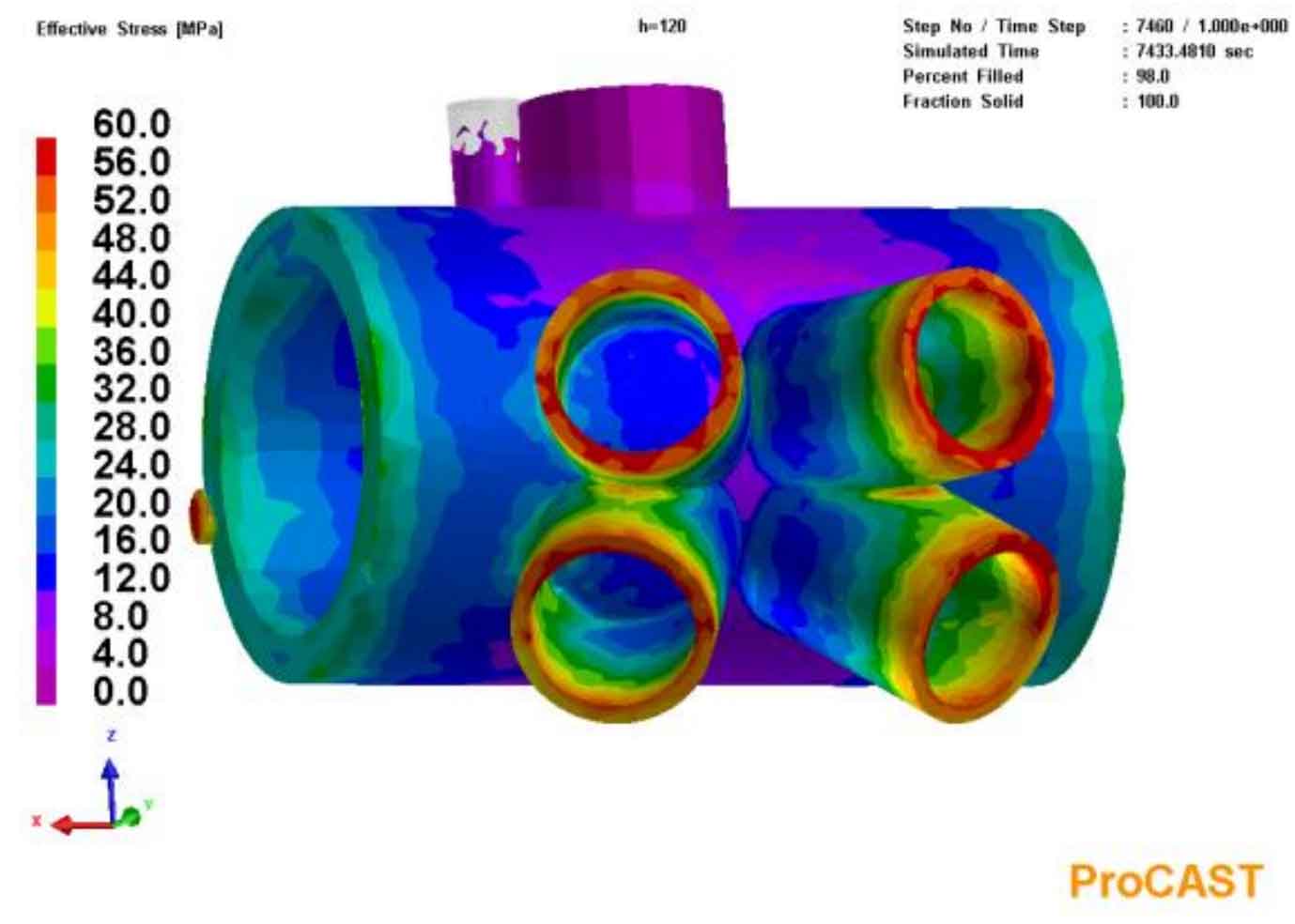

Stress Analysis

Finite element analysis revealed that the cast steel joint experiences low stress levels (maximum stress < 80 MPa), with significant safety margins. This compares favorably to traditional welded joints, which would experience much higher stress concentrations.

Case Study: Cast Steel Joint in Intersecting Tower

Bridge Design

The double-arch cable-stayed bridge employs cast steel joints at the intersection of the tower legs to address the complex loading conditions. The design ensures even stress distribution and mitigates welding-induced residual stresses.

Joint Configuration

- Material: GS-20Mn5 cast steel with optimized chemical composition and mechanical properties.

- Geometry: Thick-walled (5 cm), hollow design with internal cross-bracing and smooth transitions to prevent stress concentrations.

- Connections: Facilitates welding to the main tower tubes with designed interfaces.

Stress Analysis Results

Finite element analysis confirmed that the cast steel joint experiences low stress levels, with the maximum stress occurring in the limbs at ~80 MPa. This ensures the joint operates within its elastic range, avoiding fatigue and ensuring structural safety.

Advantages and Challenges

Advantages

- Aesthetic Appeal: Customizable geometries enhance the overall bridge design.

- Structural Integrity: Eliminates welding-induced stress concentrations.

- High Load-bearing Capacity: Thick walls and optimized geometries ensure exceptional strength.

- Versatility: Suitable for complex intersections and varying load conditions.

Challenges

- High Cost: Material and production processes are relatively expensive.

- Design Complexity: Requires detailed finite element analysis and possibly experimental validation.

- Welding Challenges: Stringent weld procedure qualifications are necessary to ensure joint integrity.

Future Directions

Standardization

As cast steel joints gain popularity, the development of standardized design, casting, and construction guidelines is crucial. This will facilitate wider adoption and ensure consistency in quality and performance.

Fatigue Analysis

Further research is needed to fully understand the fatigue behavior of cast steel joints in bridge applications, particularly under cyclic loading conditions.

Innovations in Casting Technology

Advancements in casting technology, such as 3D printing and simulation software, can improve joint designs, reduce costs, and enhance structural performance.

Environmental Considerations

Exploring sustainable casting processes and material recycling strategies will be essential for promoting the use of cast steel joints in environmentally conscious projects.

Conclusion

Cast steel joints offer significant advantages in bridge engineering, particularly in complex intersecting nodes. Their aesthetic appeal, structural integrity, and versatility make them ideal candidates for demanding design challenges. With continued research and standardization efforts, cast steel joints are poised to play an increasingly important role in the construction of modern, high-performance bridges.